Preparation method of a high-adhesion high-strength pavement repair material

A pavement repairing and high-adhesion technology, applied in the field of pavement maintenance, can solve the problems of poor bonding effect, poor mechanical strength, poor toughness, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

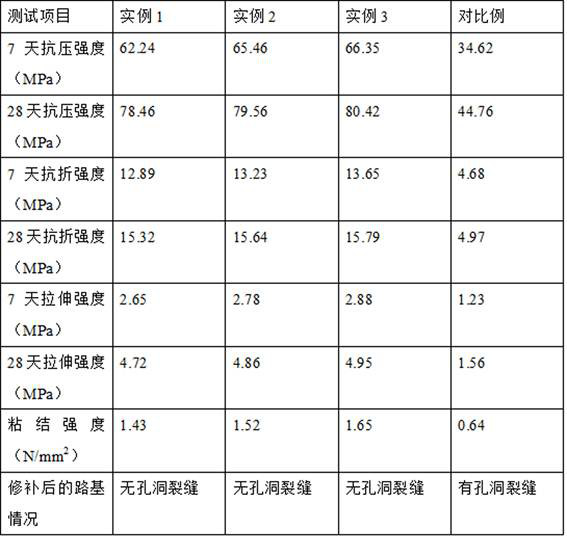

example 1

[0025]Put shrimp shells and crab shells of equal mass into an oven, dry them for 6 hours at a temperature of 55°C, put them into a grinding tank for grinding after drying, pass through a 200-mesh sieve to obtain sieved products, and sieve the sieved materials and distilled water according to the mass Put the mixture into a beaker at a ratio of 1:5, put the beaker into a water bath and let it stand at a constant temperature for 50 minutes at a water bath temperature of 60°C; add hydrochloric acid with a mass fraction of 5% to the above beaker dropwise, and adjust the pH value to 3. Soak at room temperature for 2 hours, add dropwise sodium hydroxide solution with a mass fraction of 20% to the above beaker after soaking, adjust the pH value to 10, increase the temperature of the water bath to 90°C, and filter at a constant temperature for 5 hours to obtain a filter cake. The cake was washed 4 times with distilled water, put into an oven and dried at 70°C for 3 hours to obtain a dr...

example 2

[0027] Put shrimp shells and crab shells of equal mass into an oven, dry them for 7 hours at a temperature of 57°C, put them into a grinding tank for grinding after drying, pass through a 200-mesh sieve to obtain sieved products, and sieve the sieved materials and distilled water according to the mass Put the mixture into a beaker at a ratio of 1:5, put the beaker into a water bath, and let it stand at a constant temperature for 55 minutes under the condition of a water bath temperature of 65°C; add hydrochloric acid with a mass fraction of 7% to the above beaker dropwise, and adjust the pH value to 3. Soak at room temperature for 2.5 hours. After soaking, add dropwise sodium hydroxide solution with a mass fraction of 22% to the above beaker, adjust the pH value to 11, increase the temperature of the water bath to 95°C, and filter at a constant temperature for 5.5 hours to obtain a filter cake. Wash the filter cake 6 times with distilled water, put it in an oven and dry it at 7...

example 3

[0029] Put shrimp shells and crab shells of equal mass into an oven, dry them for 8 hours at a temperature of 60°C, put them into a grinding tank for grinding after drying, and pass through a 200-mesh sieve to get the sieved product, and sieve the sieved product and distilled water according to the mass Put the mixture into a beaker at a ratio of 1:5, put the beaker into a water bath, and let it stand at a constant temperature for 60 minutes under the condition of a water bath temperature of 70°C; add hydrochloric acid with a mass fraction of 8% to the above beaker, and adjust the pH value to 4. Soak at room temperature for 3 hours, after soaking, add dropwise sodium hydroxide solution with a mass fraction of 25% to the above beaker, adjust the pH value to 12, increase the temperature of the water bath to 100°C, and filter at a constant temperature for 6 hours to obtain a filter cake. The cake was washed 8 times with distilled water, put into an oven and dried at 80°C for 5 hou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com