Epoxy resin foaming agent, epoxy resin composition and preparation and application thereof

A technology of epoxy resin and diepoxy compound, applied in the direction of organic chemistry, etc., can solve the problems of difficult to meet the low temperature construction, poor compatibility, high thermal conductivity, short storage period, high impact strength, high mechanical strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Preparation of blowing agent

[0057] 1) Under the protection of an inert gas, mix o-phenylenediamine and 1,6-hexanediol diglycidyl ether with a molar ratio of 1:0.95 evenly, raise the temperature to 65°C, and react for 1.5h;

[0058] 2) The components in (1) and sodium nitrite are mixed evenly according to the molar ratio of 1:0.95, and the sulfuric acid aqueous solution with a concentration of 60wt% is added at the same time. The molar ratio of sulfuric acid aqueous solution and nitrous acid is 1:3, and the temperature is controlled at -10 DEG C, reaction 3.5h, obtains the epoxy blowing agent of the present invention;

[0059] Blowing Agent Structural Characterization

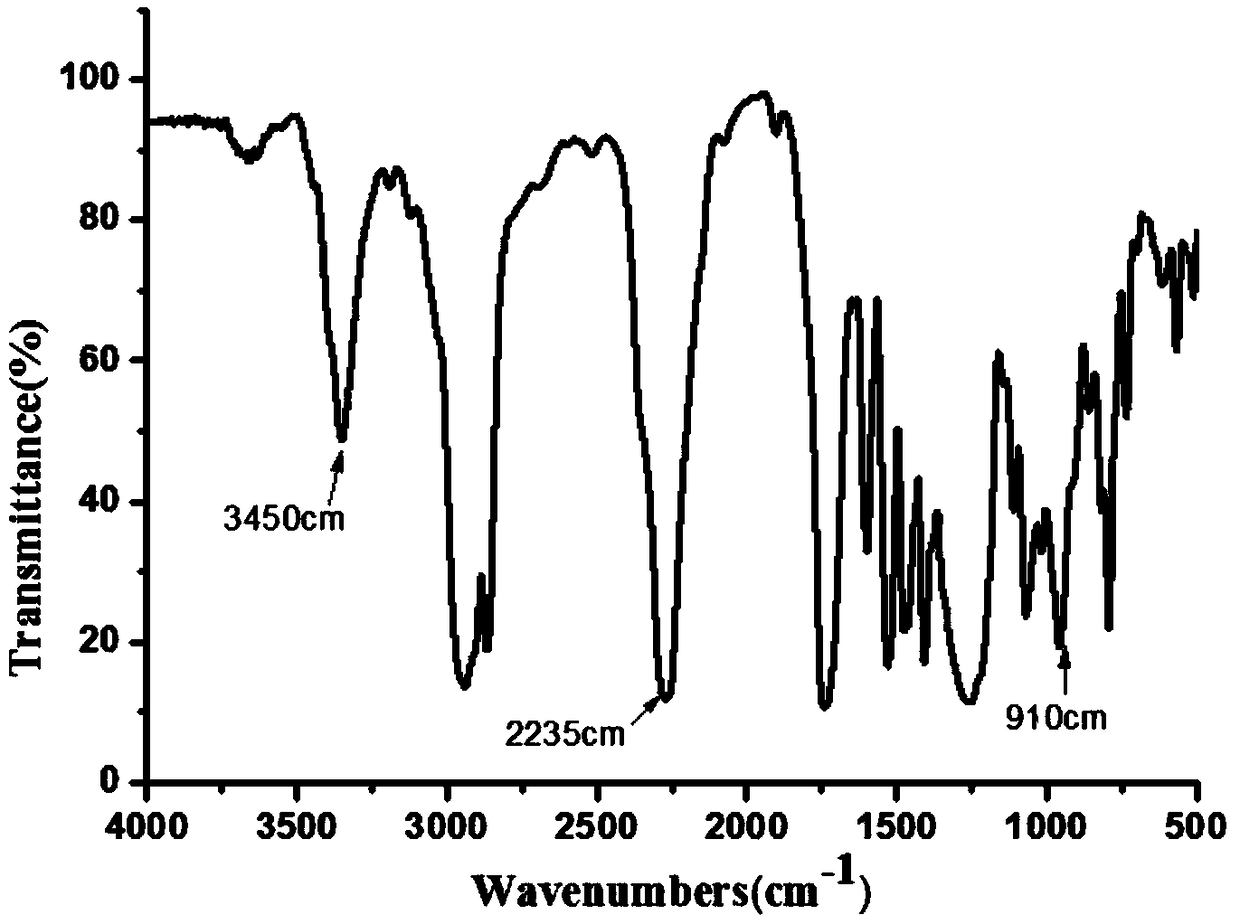

[0060] Such as figure 1 As shown in the FT-IR infrared spectrogram, it can be seen that after the reaction is completed, the 3500cm -1 The absorption peak of the primary amine in o-phenylenediamine disappears, while at 3450cm -1 The absorption peak of the secondary amine group is formed at 2235cm ...

Embodiment 2

[0066] Preparation of blowing agent

[0067] 1) Under the protection of an inert gas, mix m-phenylenediamine and 1,4-butanediol diglycidyl ether with a molar ratio of 1:1.05 evenly, raise the temperature to 75°C, and react for 1.5h;

[0068] 2) The components in (1) and sodium nitrite are mixed evenly according to the molar ratio of 1:1.05, while adding a sulfuric acid aqueous solution with a concentration of 80wt%, the molar ratio of the sulfuric acid aqueous solution to nitrous acid is 1:6, and the temperature is controlled at -5 DEG C, react for 4.7h, get the epoxy blowing agent of the present invention;

[0069] Blowing Agent Structural Characterization

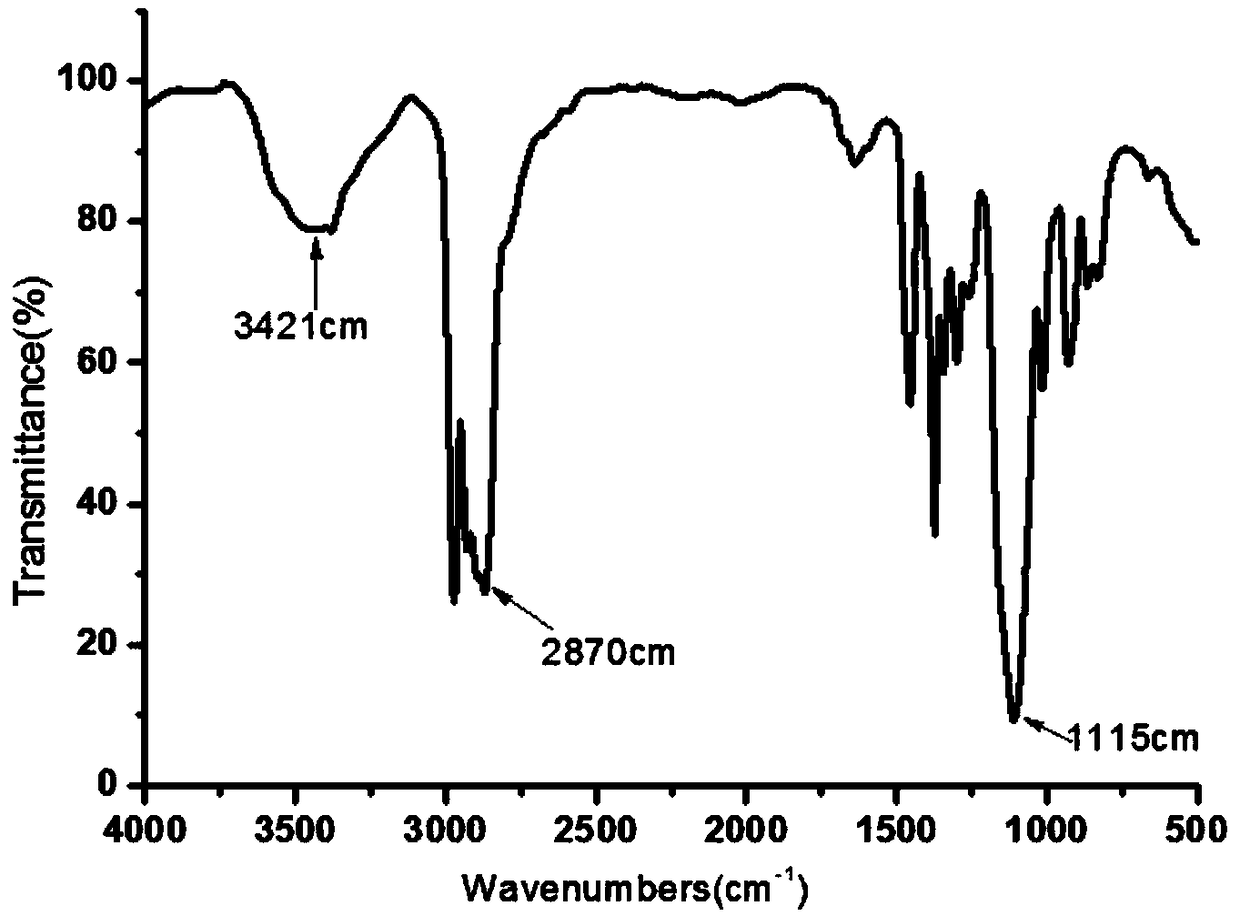

[0070] Such as figure 2 As shown in the FT-IR infrared spectrogram, it can be seen that after the reaction is completed, the 3579cm -1 The absorption peak of the primary amine in o-phenylenediamine disappears, while at 3421cm -1 The secondary amine group absorption peak is formed at 2870cm -1 for-N ⊕ ≡ N- stretchin...

Embodiment 3

[0076] Preparation of blowing agent

[0077] 1) Under the protection of an inert gas, mix m-phenylenediamine and 1,2-cyclohexanediol diglycidyl ether with a molar ratio of 1:1, heat up to 70°C, and react for 1.8 hours;

[0078] 2) Mix the components in (1) and sodium nitrite uniformly according to the molar ratio of 1:1, and simultaneously add a hydrochloric acid aqueous solution with a concentration of 10wt%, the molar ratio of the hydrochloric acid aqueous solution to nitrous acid is 1:5, and the temperature is controlled at 5 DEG C, react 4h, obtain epoxy blowing agent of the present invention;

[0079] Blowing Agent Structural Characterization

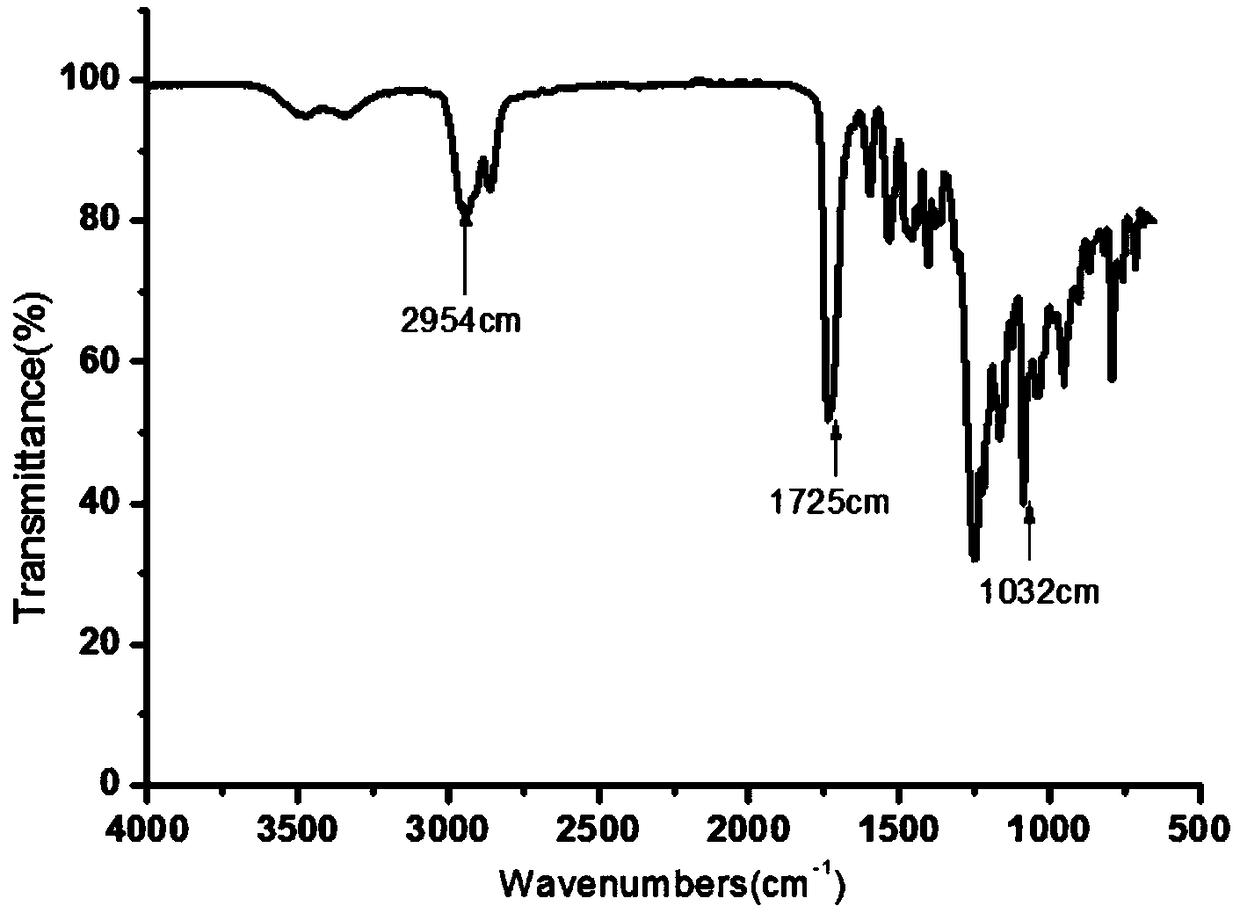

[0080] Such as image 3 As shown in the FT-IR infrared spectrogram, it can be seen that after the reaction is completed, the 3271cm -1 The absorption peak of the primary amine in o-phenylenediamine disappears, while at 2954cm -1 The absorption peak of the secondary amine group is formed at 1725cm -1 for-N ⊕ ≡ N- stretching sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com