Method for preparing biological crust sand-fixing material

A technology of biological crust and preparation steps, which is applied in the direction of soil conditioning materials, chemical instruments and methods, organic fertilizers, etc., can solve the problems of environmental secondary pollution, poor sand-fixing effect, and scarcity of raw materials, and achieve low cost and improved environmental protection. Water and water retention performance, the effect of preventing the evaporation of water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

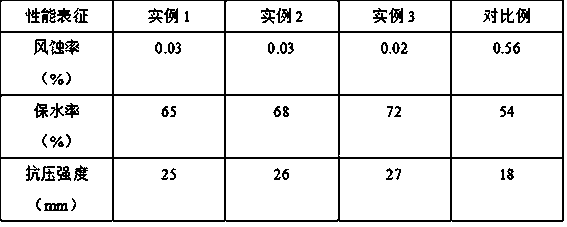

Examples

example 1

[0024]Take 100g of attapulgite stick clay and mix it with 1kg of sulfuric acid solution with a molar concentration of 3mol / L, and keep stirring at 300r / min for 10h. After the reaction is over, centrifuge to collect the precipitate, wash the precipitate with deionized water until the pH of the washing solution is 6, and then The precipitate was placed in a drying oven, dried at 100°C to constant weight, then put into a mortar and ground, and passed through a 200-mesh sieve to obtain modified attapulgite. Take 100g of urea, 30g of modified attapulgite, and 60g of biomass heat To dissolve the oil, put 200g of 37% formaldehyde solution into a beaker, stir at 300r / min for 20min, adjust the pH to 8.0 with 10% sodium hydroxide solution, keep stirring at 75°C for 40min, and then use the mass fraction Adjust pH to 5 for 5% formic acid solution, keep stirring at 80°C for 40 minutes, then adjust pH to 8.0 with 10% sodium hydroxide solution, add 60 g of biomass pyrolysis oil, keep stirring...

example 2

[0026] Take 150g of attapulgite stick clay and mix it with 1kg of sulfuric acid solution with a molar concentration of 3mol / L, and keep stirring at 350r / min for 13h. After the reaction is over, centrifuge to collect the precipitate, wash the precipitate with deionized water until the pH of the washing solution is 6, and then The precipitate was placed in a drying oven, dried to constant weight at 103°C, put into a mortar and ground, and passed through a 200-mesh sieve to obtain modified attapulgite. Take 150g of urea, 45g of modified attapulgite, and 90g of biomass heat To remove oil, put 300g of 37% formaldehyde solution into a beaker, stir at 350r / min for 25min, adjust the pH to 8.3 with 10% sodium hydroxide solution, keep stirring at 78°C for 40min, and then use the mass fraction Adjust pH to 5 for 5% formic acid solution, keep stirring at 80°C for 40 minutes, then adjust pH to 8.0 with 10% sodium hydroxide solution, add 60 g of biomass pyrolysis oil, keep stirring at 70°C f...

example 3

[0028] Take 200g of attapulgite stick clay and mix it with 2kg of sulfuric acid solution with a molar concentration of 4mol / L, and continue stirring at 400r / min for 15h. After the reaction is over, centrifuge to collect the precipitate, wash the precipitate with deionized water until the pH of the washing solution is 7, and then The precipitate was placed in a drying oven, dried to constant weight at 105°C, put into a mortar and ground, and passed through a 200-mesh sieve to obtain modified attapulgite. Take 200g of urea, 60g of modified attapulgite, and 120g of biomass heat To remove oil, put 400g of 37% formaldehyde solution into a beaker, stir at 400r / min for 30min, adjust the pH to 8.5 with 10% sodium hydroxide solution, keep stirring at 80°C for 50min, and then use the mass fraction Adjust pH to 6 for 5% formic acid solution, keep stirring at 85°C for 50 minutes, then use 10% sodium hydroxide solution to adjust pH to 8.5, add 120g of biomass pyrolysis oil, keep stirring at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com