A kind of method of highly efficient full degradation polycaprolactone

A polycaprolactone, full-degradation technology, applied in the field of fusion enzyme application, can solve the problems of pollution, slow degradation of polycaprolactone waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The cloning of embodiment 1 gene

[0037] Using the Lip gene sequence (from T.lanuginosus, the nucleotide sequence shown in SEQ ID NO.3) as a template, using primer 5'-AGAGAGGCTGAAGCTGAATTCCGGCCTGTTCGACGAGCGGT-3' and primer 5'-AGGTGGGGTTGGGTGCGCTGCTGGTTGTCGTAGGTCCATCACTCTGAAAT-3' to perform PCR amplification to obtain the fusion The Lip fragment of the enzyme Lip-Cut; using the Cut gene sequence (from T.Terrestris, the nucleotide sequence shown in SEQ ID NO.4) as a template, using primer 5'-ACCCAACCCCACCTCCAGTGGCTGCCCGAATGCCACCAAGGCCCCAACACAGCCA-3' and primer 5'-GAGATGAGTTTTTGTTCTAGAAATCAATGATGATGATGATGATGAGCATCACCAATCTT- Perform PCR amplification at 3' to obtain the Cut fragment containing the linker of the fusion enzyme Lip-Cut; use the Lip fragment and the Cut fragment of the bifunctional fusion enzyme Lip-Cut as templates, use primer 5'-AGAGAGGCTGAAGCTGAATTCCGGCCTGTTCGACGAGCGGT-3' and primer 5'- GAGATGAGTTTTTGTTCTAGAAATCAATGATGATGATGATGATGAGCATCACCAATCTT-3' was ampl...

Embodiment 2

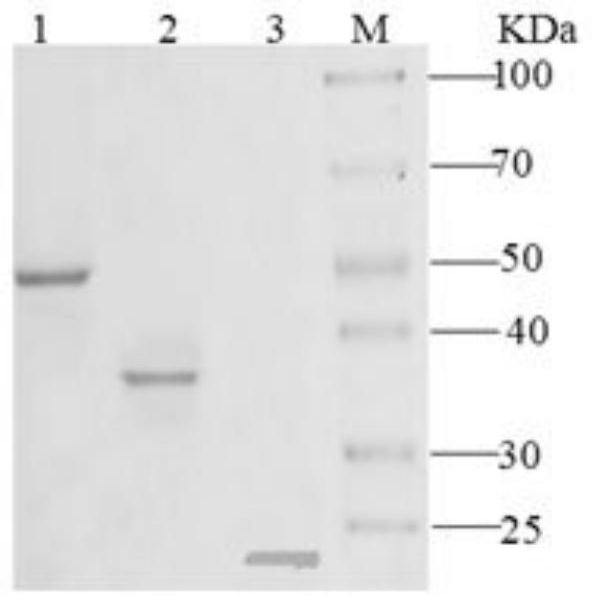

[0039] Embodiment 2 Lip, the expression and purification of Cut and Lip-Cut in P.pastoris KM71H

[0040] The positive clone DH5α with correct sequencing was inoculated into a test tube containing 3 mL of LB liquid medium, and cultured at 37°C with shaking at 200 rpm / min for about 12 hours. The mini-extraction of recombinant expression plasmids pPICZαA-Lip, pPICZαA-Cut and pPICZαA-Lip-Cut was extracted using EasyPure Plasmid MiniPrepKit of Beijing Quanshijin Biotechnology Co., Ltd. Transfer the extracted recombinant expression plasmids pPICZαA-Lip, pPICZαA-Cut and pPICZαA-Lip-Cut into P. pastoris KM71H, coat a plate containing 100 μg / mL Zeocin to screen positive clones, and insert the screened positive clones into Cultivate 100μg / mL Zeocin in 3mL YPD liquid medium on a shaker for 16-18h; inoculate the cultured bacteria solution into 50mL sterilized BMGY medium at a ratio of 1:100-1:50, at 28°C, 200rpm / min Shake culture to OD 600 =6.0-8.0; Centrifuge the bacterial solution at ...

Embodiment 3

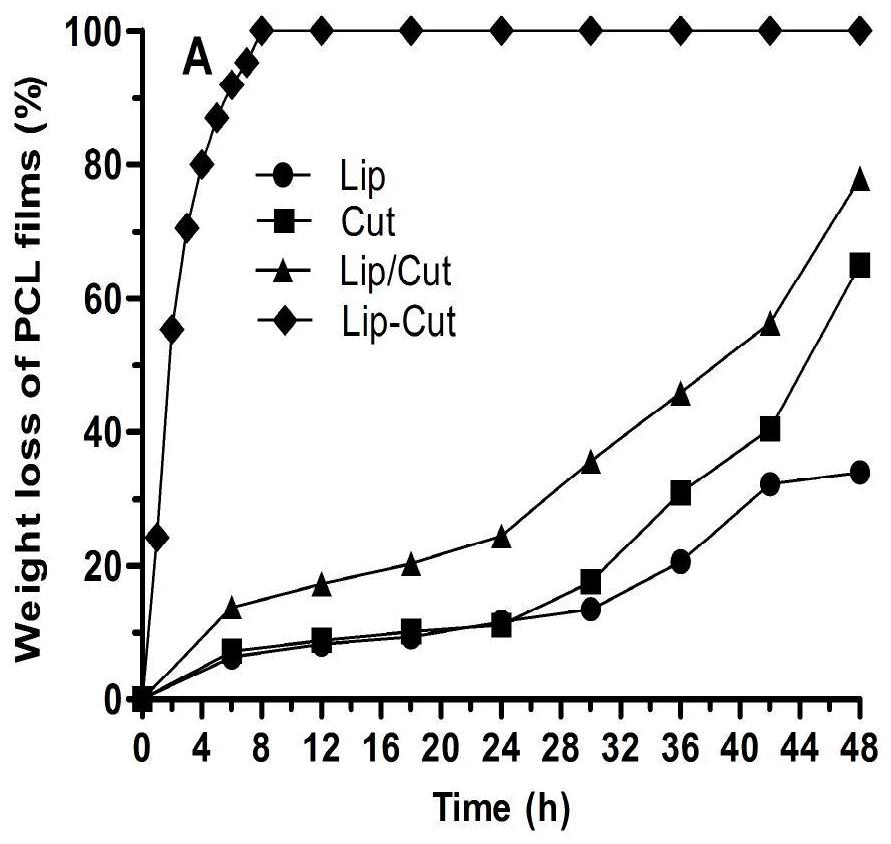

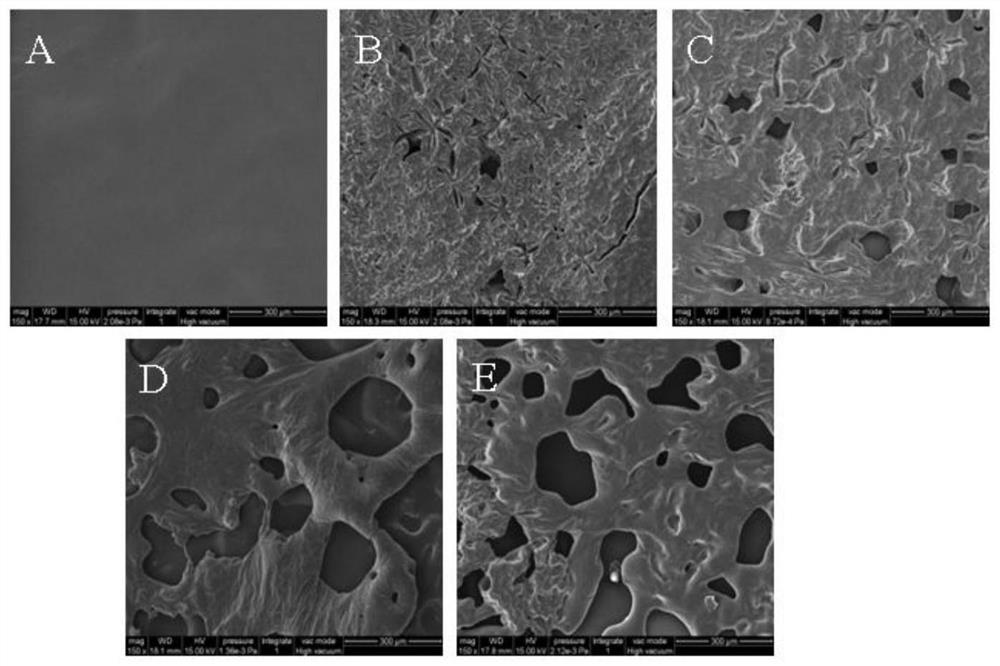

[0042] Using the bifunctional fusion enzyme Lip-Cut to degrade PCL, the steps are:

[0043] 1) Weigh 1g of polycaprolactone (PCL) and dissolve it in 100mL of chloroform, and use a magnetic stirrer RH-KT / C to stir the various polyesters evenly for about 12 hours;

[0044] 2) Put the various solutions that are completely dissolved into polytetrafluoroethylene containers and evaporate naturally for later use;

[0045] 3) Peel off the prepared various polymer films from the container, and cut it into about 5×10mm 2 samples, and then dried in a constant temperature drying oven, preserved and set aside;

[0046] 4) Add 1mL pH8.00.05M phosphate buffer (K 2 HPO 4 -KH 2 PO 4 ), various polymer films after accurate weighing, Lip, Cut and Lip-Cut with the same number of molecules (0.869nmol), at the optimum temperature (35℃Lip, 40℃Lip-Cut, 40℃ , 50°C Cut) and 150rpm / min for 48 hours of hydrolysis respectively. During the experiment, samples were taken regularly, and the control gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com