Preparation method for similarly coralloid NiSe@NC and application thereof

A coral-like, trimesic acid technology, applied in electrodes, electrolysis process, electrolysis components, etc., can solve the problem that the advantages of synergistic effect cannot be fully utilized, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

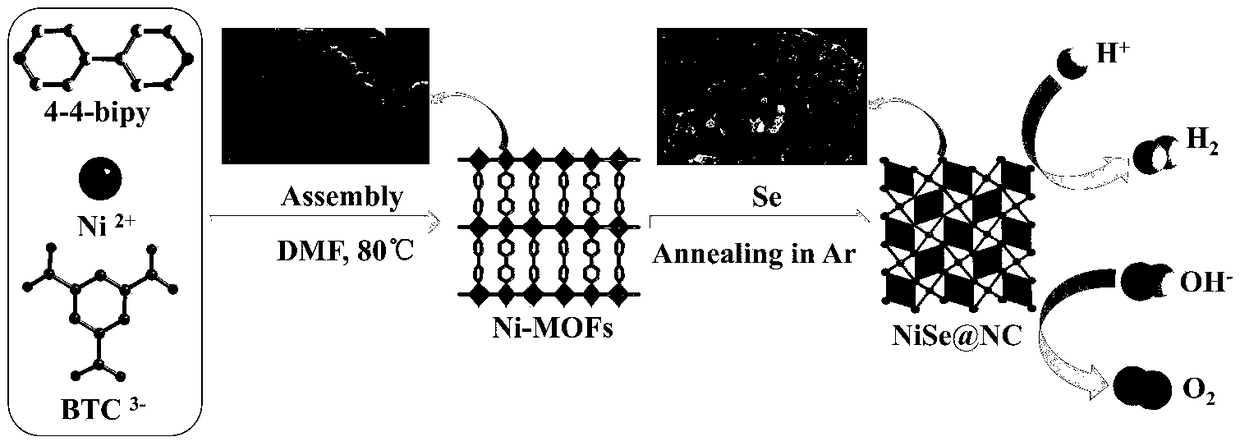

[0038] This embodiment relates to a preparation method similar to coral-like NiSe@NC, such as figure 1 As shown, it specifically includes the following steps:

[0039] Add 1 mmol of trimesic acid, 1 mmol of nickel nitrate hexahydrate, and 1 mmol of 4,4’-bipyridine to 20 mL of DMF in sequence, stir for half an hour, then transfer to a 10 mL vial, heat to 80°C, and react for 3 days. After waiting for the reaction system to drop to room temperature, take out the reaction vessel, wash the obtained green crystals with DMF and absolute ethanol three times, and then vacuum-dry them at 80°C for 24 hours to obtain Ni-MOFs;

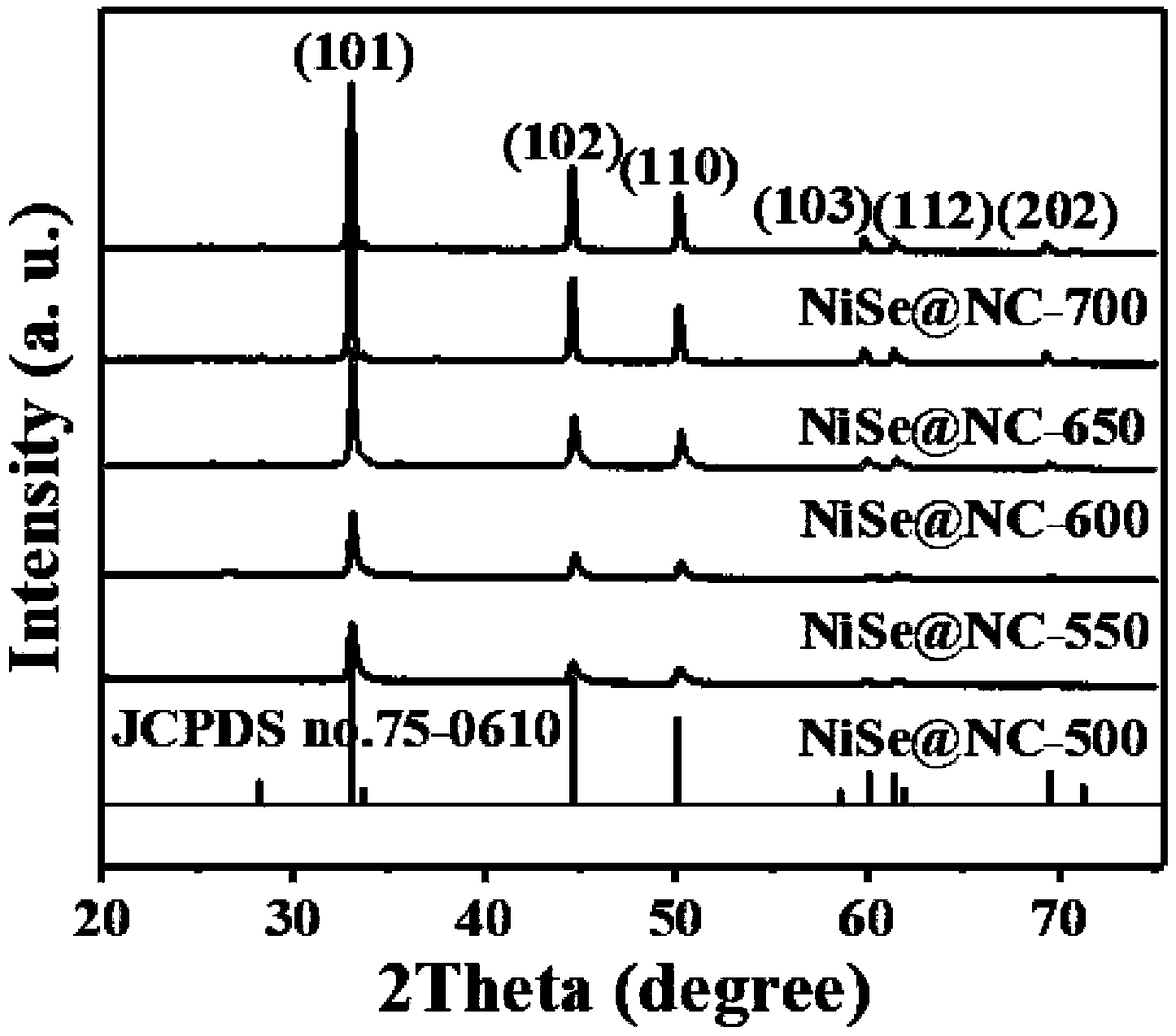

[0040] Take 200mg of Ni-MOFs and 200mg of commercial selenium powder, grind and mix them evenly with a mortar and pestle, transfer them to a square porcelain boat, and then in an argon atmosphere from room temperature to 2°C min -1 The heating rate was heated to 500 °C to obtain coral-like NiSe@NC, which was denoted as NiSe@NC-500.

Embodiment 2

[0042] This embodiment relates to a method for preparing coral-like NiSe@NC, which specifically includes the following steps:

[0043]Add 1 mmol of trimesic acid, 1 mmol of nickel nitrate hexahydrate, and 1 mmol of 4,4’-bipyridine to 20 mL of DMF in sequence, stir for half an hour, then transfer to a 30 mL vial, heat to 80°C, and react for 3 days. After waiting for the reaction system to drop to room temperature, take out the reaction vessel, wash the obtained green crystals with DMF and absolute ethanol three times, and then vacuum-dry them at 80°C for 24 hours to obtain Ni-MOFs;

[0044] Take 200mg of Ni-MOFs and 200mg of commercial selenium powder and mix them evenly with a mortar and pestle. -1 The heating rate was heated to 550 °C, and the coral-like NiSe@NC was obtained, which was denoted as NiSe@NC-550.

Embodiment 3

[0046] This embodiment relates to a method for preparing coral-like NiSe@NC, which specifically includes the following steps:

[0047] Add 1 mmol of trimesic acid, 1 mmol of nickel nitrate hexahydrate, and 1 mmol of 4,4’-bipyridyl into 20 mL of DMF in sequence, stir for half an hour, then transfer to a 10 mL vial, heat to 80°C, and react for 3 days. After waiting for the reaction system to drop to room temperature, take out the reaction vessel, wash the obtained green crystals with DMF and absolute ethanol three times, and then vacuum-dry them at 80°C for 24 hours to obtain Ni-MOFs;

[0048] Take 200mg of Ni-MOFs and 200mg of commercial selenium powder and mix them evenly with a mortar and pestle. -1 The heating rate is heated to 600 °C, and the coral-like NiSe@NC is obtained, which is denoted as NiSe@NC-600.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com