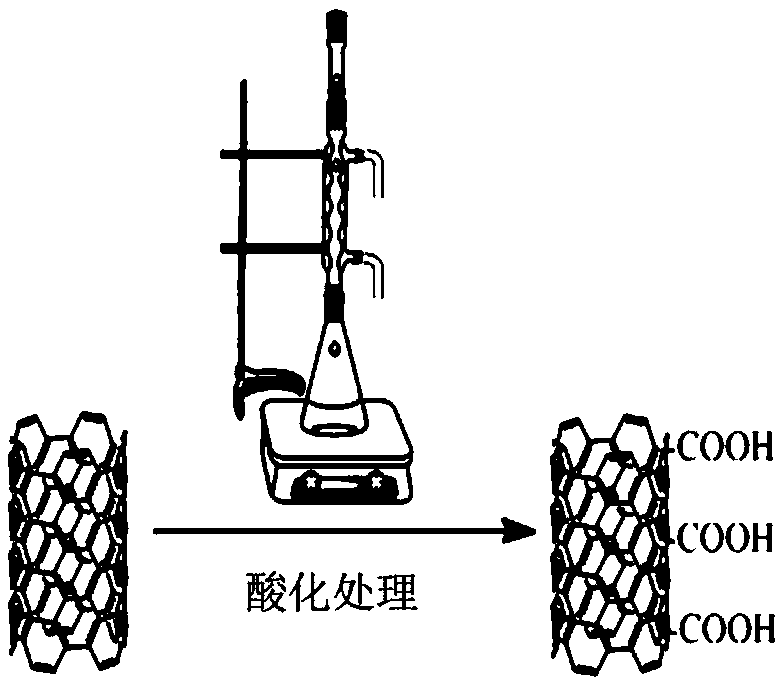

Preparation method of modified ultrafiltration membrane co-coated by utilizing dopamine and functional CNTs (Carbon Nanotubes)

A technology of carbon nanotubes and ultrafiltration membranes, applied in chemical instruments and methods, ultrafiltration, membranes, etc., can solve the problems of increased membrane resistance, poor antibacterial performance, and low flux, so as to prolong service life and improve flux , the effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1. In this embodiment, the preparation method of the modified ultrafiltration membrane co-coated with dopamine and functionalized carbon nanotubes is carried out according to the following steps:

[0034] Step 1. Put 12g polysulfone, 4g PEG200 and 84g N,N-dimethylformamide into a 250mL Erlenmeyer flask. Seal the mouth of the flask with plastic wrap. Place the Erlenmeyer flask on a magnetic heating stirrer at 60℃. , Magnetic stirring for 8h at 400r / min, and degassing at room temperature for 24h to form a homogeneous casting solution;

[0035] Step 2. Stick a PET non-woven fabric with a thickness of 40 μm on a smooth glass plate with adhesive tape, adjust the height of the doctor blade to 80 μm, and use the doctor blade to evenly coat the casting liquid formed in step 1 on the non-woven fabric. Stay at room temperature for 1 min, then place the entire glass plate in N-methylpyrrolidone deionized water with a concentration of 3wt% at 25°C to complete the gel process;...

Embodiment 2

[0040] Embodiment 2. In this embodiment, the preparation method of co-coating modified ultrafiltration membrane with dopamine and functionalized carbon nanotubes is carried out according to the following steps:

[0041] Step 1. Add 12g polyethersulfone, 4g PVPk30 and 84g N-methylpyrrolidone into a 250mL Erlenmeyer flask, seal the mouth of the flask with plastic wrap, and place the Erlenmeyer flask on a magnetic heating stirrer at 60°C, 400r / Magnetic stirring for 8 hours under the condition of min, and degassing at room temperature for 24 hours to form a homogeneous casting solution;

[0042] Step 2. Stick a PET non-woven fabric with a thickness of 80 μm on a smooth glass plate with adhesive tape, adjust the height of the doctor blade to 120 μm, and use a doctor blade to uniformly coat the casting liquid formed in step 1 on the non-woven fabric. Stay at room temperature for 1 min, then place the entire glass plate in N-methylpyrrolidone deionized water with a concentration of 3wt% ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com