Photocatalytic material of gold nanorod coated with palladium nanoparticles at both ends and preparation method of photocatalytic material

A photocatalytic material and technology of gold nanorods, which are applied in the field of catalyst preparation, can solve problems such as the disadvantage of using gold nanorods, and achieve the effects of broad application prospects, mild reaction conditions and simple preparation methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The synthesis of gold nanorods includes the preparation of seed solution and the preparation of growth solution. Preparation of seed solution. HAuCl 4 ·3H 2 O was added to cetyl ammonium bromide (CTAB) solution to form Au(III)-CTAB complex, and NaBH 4 For reduction, react under certain conditions for a period of time before use. During the preparation of the seed solution, under stirring conditions, take HAuCl at a molar ratio of 1:(2~5):(300~500) 4 ·3H 2 O, cetyl ammonium bromide (CTAB) and NaBH 4 Add water until well combined. During the synthesis of the gold nanorods, during the preparation of the seed solution, NaBH was added 4 Afterwards, it needs to be vigorously stirred for 0.5-2 minutes. The reaction condition is to stand still at 25-45°C for 30-150 minutes, preferably at 30-35°C for 30-90 minutes.

[0041] Preparation of growth solution. Dissolve the surfactant cetyl ammonium bromide and sodium oleate in hot water at 30-90°C (preferably 40-90°C). After...

Embodiment 1

[0048] Example 1: Preparation of gold nanorods

[0049] Preparation of seed solution, take 0.1M CTAB solution 10mL and 0.5mM chloroauric acid solution 5mL, place in a weighing bottle with a capacity of 30mL, wait for the two to mix evenly, inject 1mL of fresh 6mM sodium borohydride solution into it , stir vigorously for 30s, and let stand at 27°C for 30min before use;

[0050] For the preparation of the growth solution, measure 250mL of ultrapure water at 60°C, place it in a conical flask with a capacity of 500mL, then weigh 7g of cetyl ammonium bromide and 1.534g of sodium oleate, and add them to the above conical flask In the bottle, stir until all the raw materials are dissolved; when the solution is cooled to room temperature, add 20 mL of 4 mM silver nitrate to the solution, and let stand at room temperature for 15 min; then add 250 mL of 1 mM chloroauric acid solution to the solution, and stir at 700 rpm for 60 min; Add 3.2mL of concentrated hydrochloric acid (37wt%) to...

Embodiment 2

[0061]Gold nanorod sample described in embodiment 1 (the mol ratio of described gold nanorod and chloropalladium acid is 1:1) is dispersed in the cetyl ammonium chloride solution of concentration 0.1M volume 50mL, takes out gold therefrom Dilute 2 mL of nanorod colloid to 20 mL; under stirring conditions, add 100 μL of 0.1M chloropalladium acid and 400 μL of 10 mM silver nitrate to the solution at the same time; next, add 60 μL of 25 mM ascorbic acid to the solution; the solution is reacted at 27 ° C 12h, the mol ratio of the gold nanorod and the nano-palladium particle in the photocatalytic material coated at the two ends of the gained gold nanorod and the nano-palladium particle is 1:1;

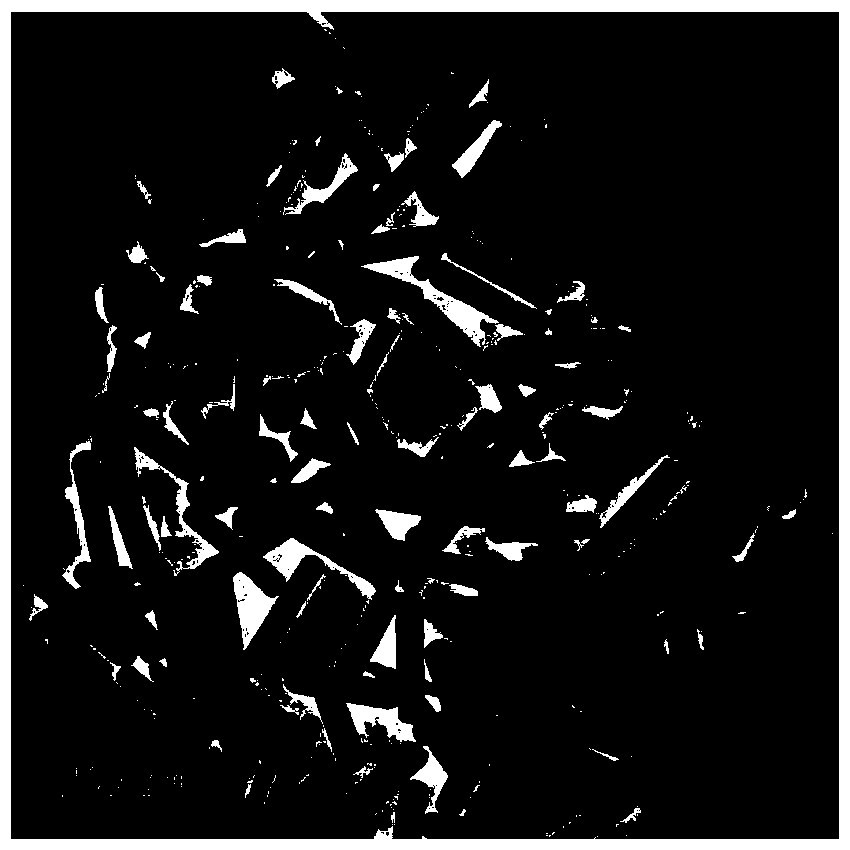

[0062] Figure 4 It is the TEM photo of the photocatalytic material prepared in Example 2, and the results show that the photocatalytic material prepared is wrapped with nano-palladium particles (particle diameter is about 12.6-15.1nm) at the two ends of the gold nanorod, and the middle of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com