Novel compound rock wool and aerogel insulation board and preparation method thereof and compound board

An aerogel, thermal insulation board technology, applied in thermal insulation, glass manufacturing equipment, manufacturing tools and other directions, can solve the problems of cumbersome preparation process, easy to burn, unable to be installed on the wall, etc., to shorten the preparation process, control the amount of addition, The effect of improving thermal insulation performance and water repellency performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment example 1

[0031] A preparation method of composite rock wool aerogel insulation board, which comprises the following steps:

[0032] Preparation of rock wool thread: crush the ore into a cupola at a temperature of 1470°C to 1570°C, fill with liquid oxygen and melt, and the magma is thrown out by a four-roll centrifuge at a high speed of 6200 to 8000 revolutions / min. Form rock wool silk;

[0033] Prepare the rock wool bundle: spray phenolic resin binder synchronously when spinning the cotton in the four-roll centrifuge, spray silica aerogel evenly on the opening above the cotton collector, and the rock wool yarn is continuously collected during the centrifugal rotation of the cotton collector. Until the exit of the cotton collector, a composite rock wool aerogel rock wool bundle is formed;

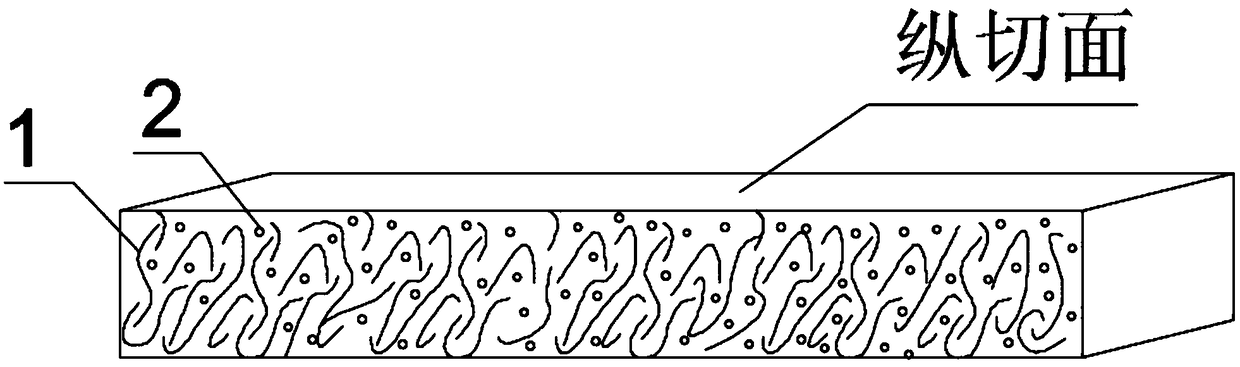

[0034] Preparation of rock wool board: a plurality of rock wool bundles are pleated and laid flat by a pendulum machine, and then sent to a cotton pressing machine and a curing furnace, and the composite r...

specific Embodiment example 2

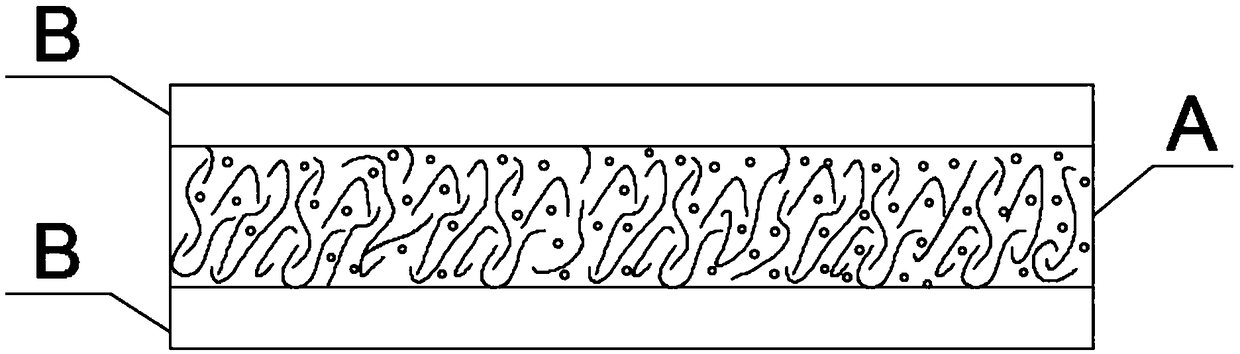

[0040] The present invention also proposes a composite rock wool aerogel thermal insulation belt including specific implementation case 1, which is formed by slitting the composite rock wool aerogel thermal insulation board according to the required thickness, changing the horizontal filaments into vertical filaments, and improving the tensile strength , To ensure the surface flatness.

specific Embodiment example 3

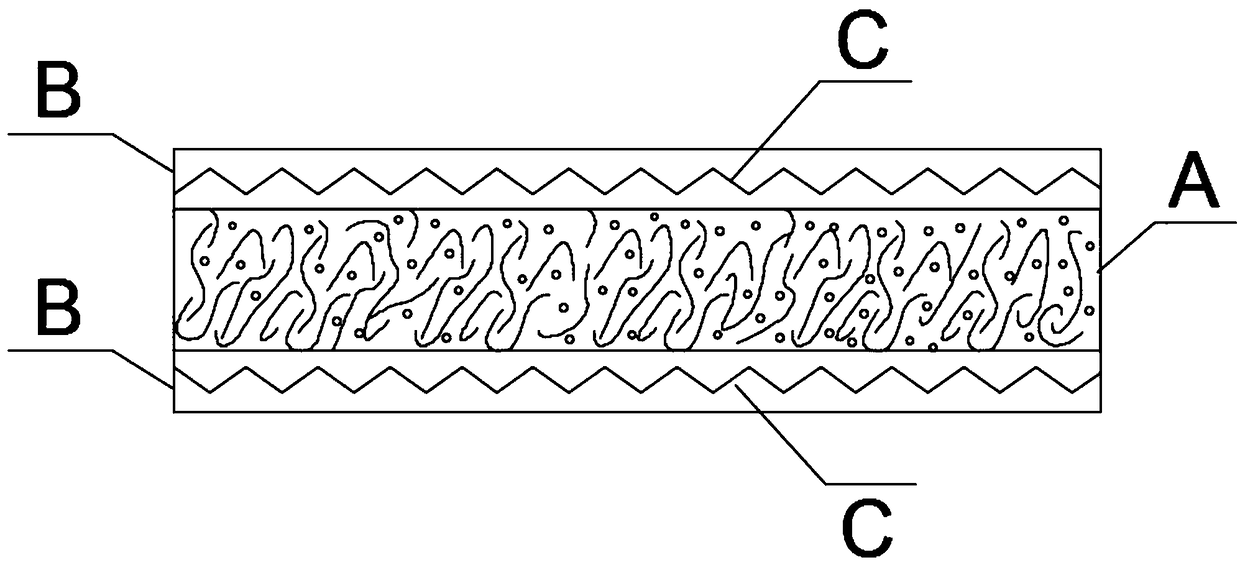

[0042] The present invention also proposes a composite board containing the composite rock wool aerogel insulation belt of specific implementation case 2 (also called a rock wool belt combination board), which includes a composite rock wool aerogel insulation board body A, a mortar layer B, and a grid The cloth C is characterized in that: the mortar layer B is located on both sides of the longitudinal section of the main body A of the composite rock wool aerogel insulation board, and a layer of mesh cloth C is also provided in the mortar layer, which has the function of reinforcement and crack resistance.

[0043] Specific implementation case 2 and specific implementation case 3 include the above composite rock wool aerogel insulation tape and its composite board, which not only has excellent thermal insulation performance and low thermal conductivity, but also can effectively improve the adhesion between the product and the mortar. The working principle of the attachment force is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com