A kind of carbon microsphere copper-silver alloy, modified lubricating grease, preparation method and application

A technology of copper-silver alloy and carbon microspheres, which is applied in lubricating compositions, additives, petroleum industry, etc., can solve the problems of reduced surface roughness and increased friction coefficient of materials, and achieves reduced friction, high strength and hardness, green and pollution-free The Effect of Atom Utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] (1) Add copper nitrate, silver nitrate and glucose into distilled water according to the molar ratio of 2.83:1:17.6, and mix well to obtain mixed solution 1;

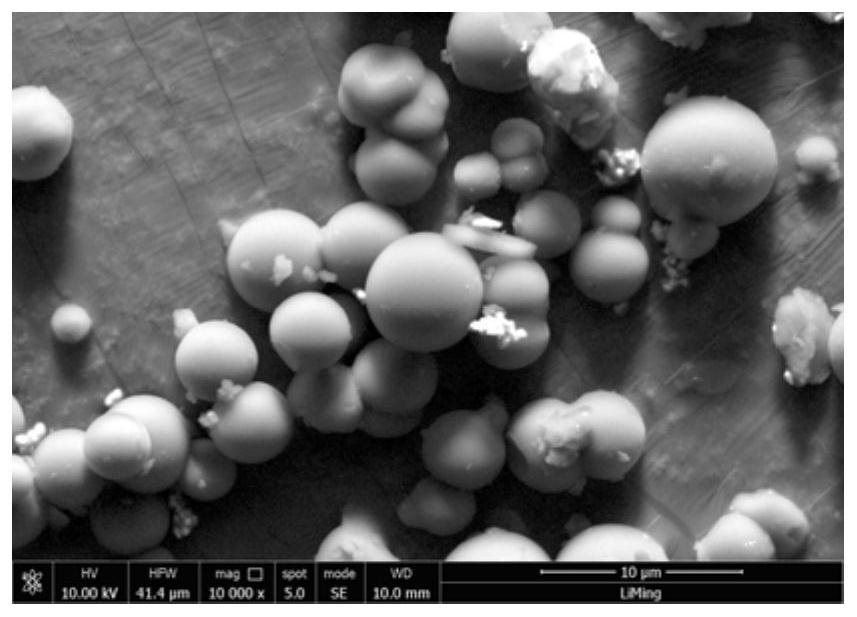

[0055] (2) Add L-ascorbic acid solution to the mixed solution 1 prepared in step (1), and mix evenly to obtain a mixed solution 2, wherein the molar ratio of copper nitrate to L-ascorbic acid is 2.83:12.6, and glucose in the mixed solution 2 The concentration is 0.5mol / L; the mixed solution 2 is poured into a stainless steel autoclave lined with polytetrafluoroethylene, and subjected to a hydrothermal reaction at 180°C for 6 hours; after the reaction, it is cooled naturally, and then washed with deionized water and ethanol respectively, 80 ℃ vacuum drying for 6h to obtain carbon microsphere copper-silver alloy ( figure 1 );

[0056] (3) Add part of the base oil (2 / 3 of the total mass of the base oil) and lithium lauryl stearate soap into the reaction kettle, stir and heat up until the base oil and lithium lauryl...

Embodiment 2

[0060] (1) Add copper nitrate, silver nitrate and glucose into distilled water according to the molar ratio of 2.83:1:17.6, and mix well to obtain mixed solution 1;

[0061] (2) Add L-ascorbic acid solution to the mixed solution 1 prepared in step (1), and mix evenly to obtain a mixed solution 2, wherein the molar ratio of copper nitrate to L-ascorbic acid is 2.83:12.6, and the glucose in the mixed solution 2 The concentration of the mixture is 0.5mol / L; pour the mixed solution 2 into a stainless steel autoclave lined with polytetrafluoroethylene, and conduct a hydrothermal reaction at 180°C for 7 hours; after the reaction, cool it naturally, and then wash it with deionized water and ethanol respectively, and wash it with deionized water and ethanol for 80 ℃ vacuum drying for 6 hours to obtain carbon microsphere copper-silver alloy;

[0062] (3) Add part of the base oil (2 / 3 of the total mass of base oil) and lithium lauryl stearate soap into the reaction kettle, stir and heat...

Embodiment 3

[0066] (1) Add copper nitrate, silver nitrate and glucose into distilled water according to the molar ratio of 2.83:1:17.6, and mix well to obtain mixed solution 1;

[0067] (2) Add L-ascorbic acid solution to the mixed solution 1 prepared in step (1), and mix evenly to obtain a mixed solution 2, wherein the molar ratio of copper nitrate to L-ascorbic acid is 2.83:12.6, and the glucose in the mixed solution 2 The concentration of the mixture is 0.5mol / L; the mixed solution 2 is poured into a stainless steel autoclave lined with polytetrafluoroethylene, and subjected to a hydrothermal reaction at 180°C for 8 hours; after the reaction, it is naturally cooled, and then washed with deionized water and ethanol respectively, 80 ℃ vacuum drying for 6h; obtain carbon microsphere copper-silver alloy;

[0068] (3) Add part of the base oil (2 / 3 of the total mass of the base oil) and lithium lauryl stearate soap into the reaction kettle, stir and heat up until the base oil and lithium lau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com