Foam cobalt in-situ vulcanization nanoflower spherical Co4S3@Co hydrogen evolution material and method for preparing same

A foam, hydrogen evolution technology, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve the problems of poor material cycle stability, high hydrogen evolution overpotential, and achieve high stability, simple process, The effect of excellent electrocatalytic hydrogen production performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

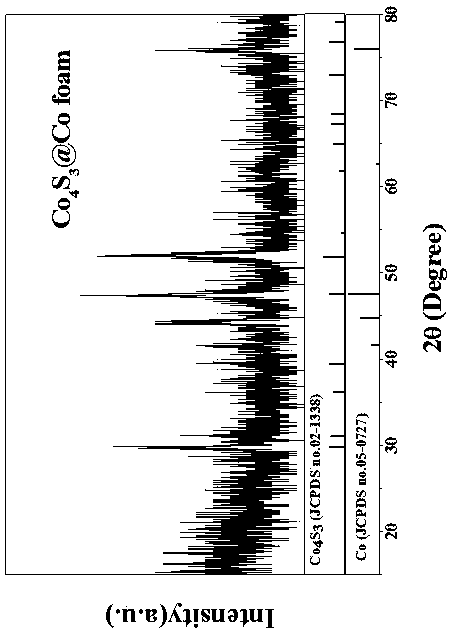

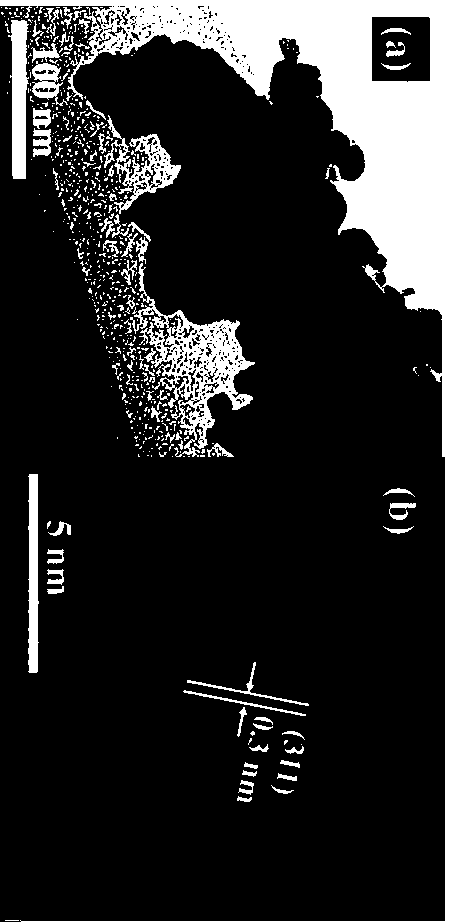

Embodiment 1

[0031] (1) Cut the foamed cobalt into 2×2.5 cm strips, place them in acetone, absolute ethanol and distilled water for ultrasonic cleaning for 10 min, and etch the cleaned foamed cobalt in 1% nitric acid for 15 minutes. min, washed with distilled water; (2) Accurately weigh the product obtained in step (1), and weigh thiosemicarbazide according to the ratio of cobalt source to sulfur source material as 2: 3; (3) Weigh the product in step (2) Dissolve the obtained thiosemicarbazide into 140 mL of deionized water and absolute ethanol (equal volume) mixed solution, add 0.5% galactose with a molar mass of thiosemicarbazide dropwise, stir evenly and immerse the cobalt foam obtained in step (1) into Wherein; (4) Transfer 200 mL of the mixture obtained in step (3) to a polytetrafluoroethylene-lined autoclave, and ° After performing solvothermal reaction at C for 10 h, cool down to room temperature naturally, wash with deionized water repeatedly, then wash with absolute ethanol, and d...

Embodiment 2

[0033] (1) Cut the foamed cobalt into 2×2.5 cm strips, place them in acetone, absolute ethanol and distilled water for cleaning and ultrasonic cleaning for 10 min, and etch the cleaned foamed cobalt in 1% hydrochloric acid for 10 minutes. min, washed with distilled water; (2) Accurately weigh the product obtained in step (1), and weigh thiourea according to the ratio of cobalt source to sulfur source material as 3:2; (3) Weigh the product in step (2) thiourea was dissolved in 140 mL of deionized water and absolute ethanol (equal volume) mixed solution, 1.0% thiourea molar glucose was added dropwise, and after stirring evenly, the foamed cobalt obtained in step (1) was immersed in it; (4 ) Transfer 200 mL of the mixture obtained in step (3) to a polytetrafluoroethylene-lined autoclave at 160 ° After solvothermal reaction at C for 8 h, cool down to room temperature naturally, wash with deionized water repeatedly, then wash with absolute ethanol, and dry for later use; (5) Place ...

Embodiment 3

[0035] (1) Cut the foamed cobalt into 2×2.5 cm strips, place them in acetone, absolute ethanol and distilled water for ultrasonic cleaning for 10 min respectively, and etch the cleaned foamed cobalt in 2% sulfuric acid for 20 minutes. min, washed with distilled water; (2) Accurately weigh the product obtained in step (1), and weigh thiourea dioxide according to the ratio of cobalt source and sulfur source material as 1:1; (3) Weigh the product obtained in step (2) Dissolve thiourea dioxide in 140 mL of deionized water and absolute ethanol (equal volume) mixed solution, add 2.0% thiourea dioxide molar amount of fructose dropwise, stir well and immerse the cobalt foam obtained in step (1); (4 ) Transfer 200 mL of the mixture obtained in step (3) to a polytetrafluoroethylene-lined autoclave at 170 ° After solvothermal reaction at C for 8 h, cool down to room temperature naturally, wash with deionized water repeatedly, then wash with absolute ethanol, and dry for later use; (5) Pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com