Clothes-washing gel bead and preparation method thereof

A technology for laundry beads and fat, which is applied to chemical instruments and methods, detergent compositions, soap detergent compositions, etc., can solve the problem of poor antibacterial performance, decontamination effect and antibacterial performance to be further improved, and decontamination. Unsatisfactory effect and other problems, to achieve the effect of maintaining stability, efficient synergistic decontamination effect, and maintaining fabric color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

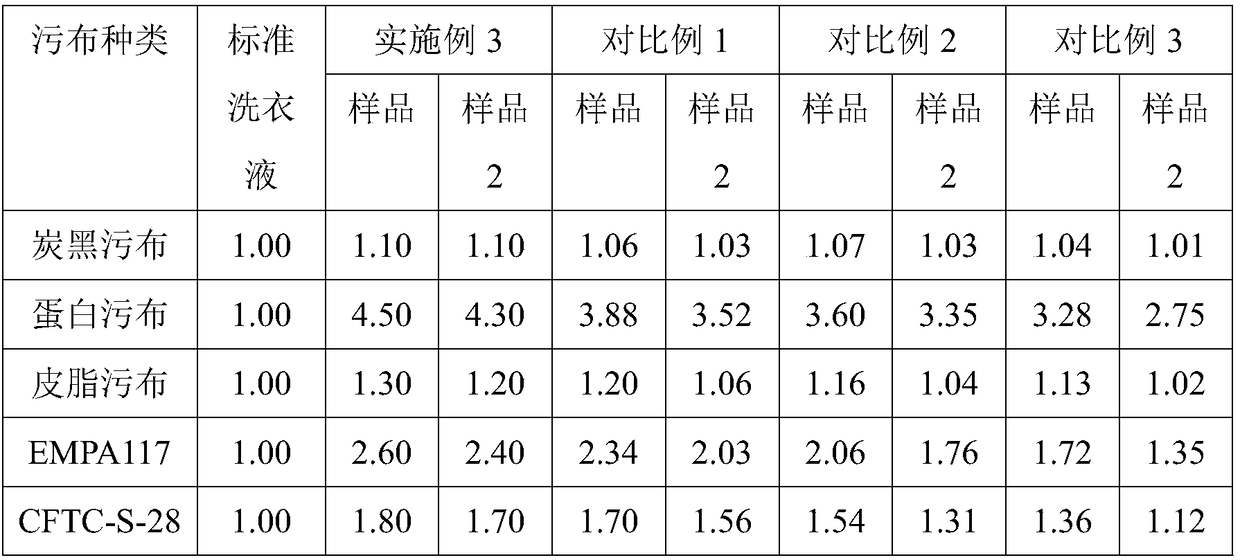

Examples

Embodiment 1

[0041] Embodiment 1, a kind of washing beads

[0042] The laundry pod consists of the following components and their mass percentages: 30% fatty alcohol polyoxyethylene ether, 10% glycerin, 15% propylene glycol, 10% potassium laurate, 12% fatty acid methyl ester ethoxylate, deionized Water 5.195%, acrylic acid-acrylate copolymer 5%, organosilicon compound 5%, fragrance 5%, compound enzyme 0.8%, microcapsule fragrance 0.6%, silver ion compound 0.5%, glutamic acid N,N-acetoacetate tetra Sodium 0.5%, antiseptic 0.2%, pigment 0.005%, citric acid 0.2%; Described fatty alcohol polyoxyethylene ether is by fatty alcohol polyoxyethylene ether (EO number is 7) and fatty alcohol polyoxyethylene ether (EO number is 7) and fatty alcohol polyoxyethylene ether (EO number is 7) 9) Composed of 20:30 by mass ratio; the complex enzyme is composed of clathrate of protease, lipase, amylase and cellulase by mass ratio of 7:7:4:2; the preservative is composed of 5-chloro - Composition of 2-methyl-4...

Embodiment 2

[0050] Embodiment 2, a kind of laundry beads

[0051] The laundry pod consists of the following components and their mass percentages: 63% fatty alcohol polyoxyethylene ether, 5% glycerin, 10% propylene glycol, 8% potassium laurate, 5% fatty acid methyl ester ethoxylate, deionized Water 5.439%, acrylic acid-acrylate copolymer 1%, organosilicon compound 1%, fragrance 1%, compound enzyme 0.2%, microcapsule fragrance 0.1%, silver ion compound 0.1%, glutamic acid N,N-acetoacetate tetra Sodium 0.1%, antiseptic 0.01%, pigment 0.001%, citric acid 0.05%; Described fatty alcohol polyoxyethylene ether is by fatty alcohol polyoxyethylene ether (EO number is 7) and fatty alcohol polyoxyethylene ether (EO number is 7) and fatty alcohol polyoxyethylene ether (EO number is 7) 9) Composed of 45:10 by mass ratio; the complex enzyme is composed of clathrate of protease, lipase, amylase and cellulase by mass ratio of 10:5:2:1; the preservative is composed of 5-chloro - Composition of 2-methyl-4...

Embodiment 3

[0056] Embodiment 3, a kind of washing beads

[0057] The laundry pod consists of the following components and their mass percentages: 46% fatty alcohol polyoxyethylene ether, 6% glycerin, 10% propylene glycol, 10% potassium laurate, 10% fatty acid methyl ester ethoxylate, deionized Water 8.418%, acrylic acid-acrylate copolymer 2%, organosilicon compound 3%, fragrance 3%, compound enzyme 0.4%, microcapsule fragrance 0.4%, silver ion compound 0.3%, glutamic acid N,N-acetoacetic acid tetra Sodium 0.3%, preservative 0.08%, pigment 0.002%, citric acid 0.1%; Described fatty alcohol polyoxyethylene ether is by fatty alcohol polyoxyethylene ether (EO number is 7) and fatty alcohol polyoxyethylene ether (EO number is 7) and fatty alcohol polyoxyethylene ether (EO number is 7) 9) composition by mass ratio 21:25; described compound enzyme is composed of clathrate of protease, lipase, amylase and cellulase by mass ratio 9:6:3:1; described preservative is composed of 5-chloro - Compositi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com