Hydrophilic treatment method of ITO (indium tin oxide) substrate

A hydrophilic treatment and substrate technology, which is applied in the manufacture of electrical components, electrical solid devices, semiconductor/solid devices, etc., can solve the problems that the surface of ITO is not very hydrophilic and cannot be treated with ITO

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

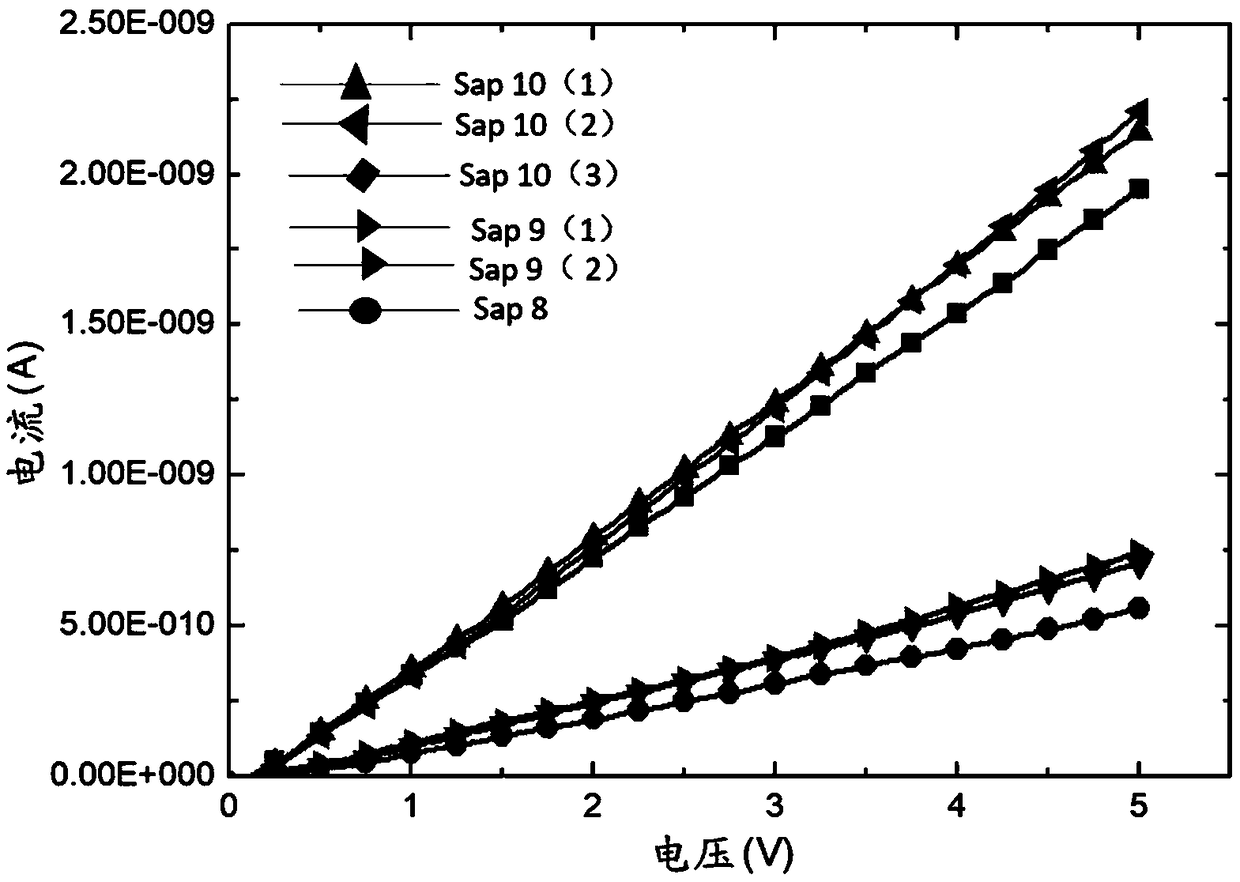

Examples

Embodiment approach

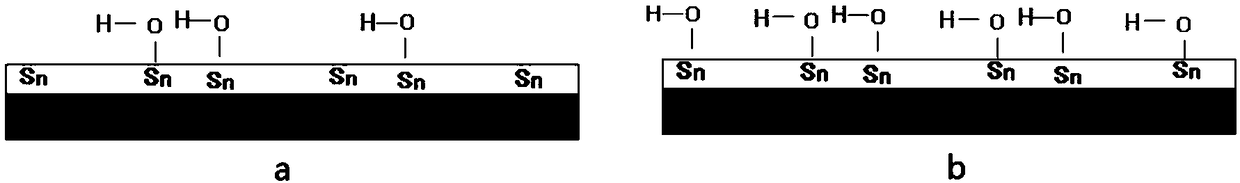

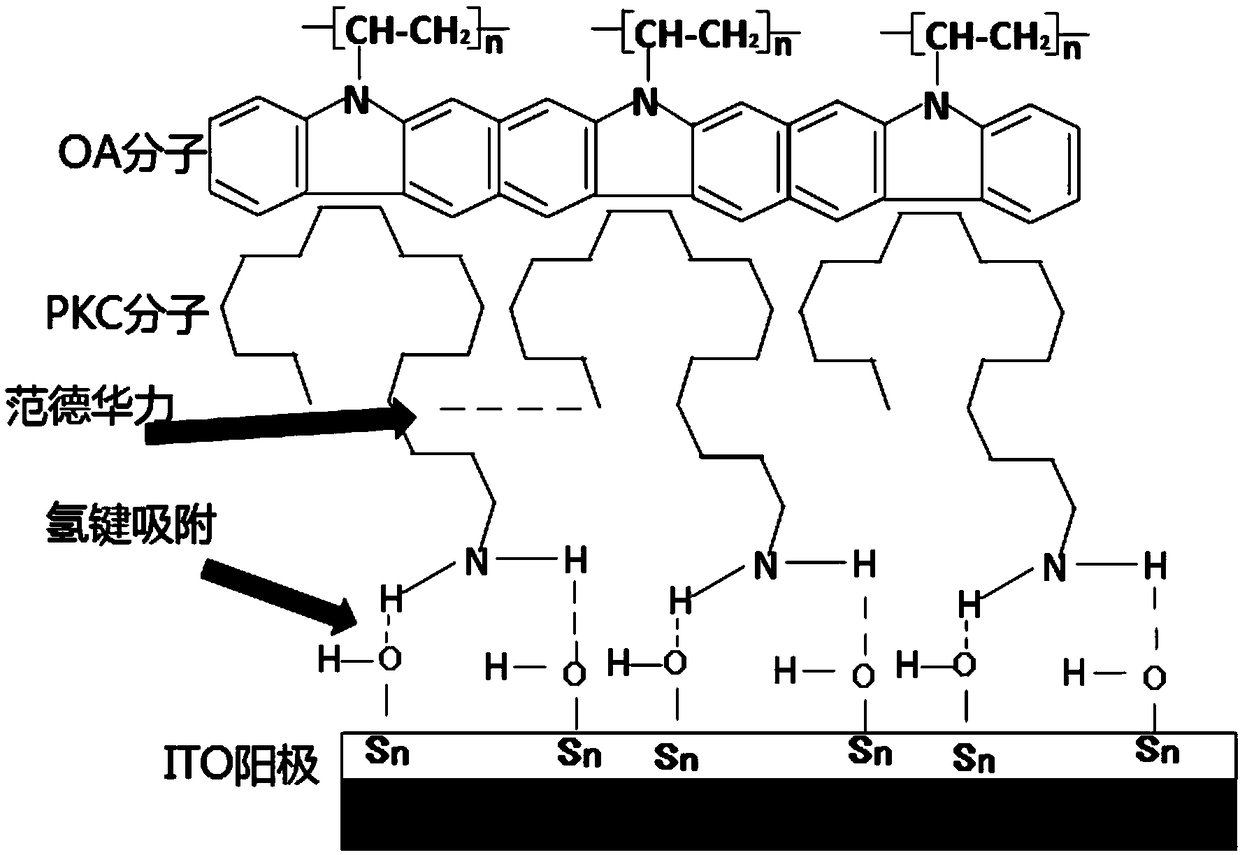

[0033] According to one embodiment of the present invention, the hydrophilic treatment method includes the following steps:

[0034] The ITO substrate is treated with the first solvent, the second solvent, the mixed solution of concentrated acid and hydrogen peroxide, and water in sequence, and the treated ITO substrate is dried.

[0035] According to one embodiment of the present invention, the first solvent is selected from one or more of ethanol, acetone, and isopropanol. According to one embodiment of the present invention, the first solvent is selected from ethanol. The second solvent is selected from one or more of chloroform, benzene, carbon tetrachloride, and methoxyethanol. According to one embodiment of the present invention, the second solvent is selected from chloroform.

[0036] According to one embodiment of the present invention, the water is selected from deionized water or distilled water.

[0037] According to one embodiment of the present invention, the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com