Preparation method and application of photocatalyst

A technology of photocatalyst and ammonium chloride, which is applied in the field of photocatalysis, can solve the problems of high cost, cumbersome steps, and unsatisfactory photocatalytic effect, and achieve the effects of improving catalytic stability, catalytic activity, and specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Under the atmosphere of nitrogen gas in a closed container, guanidine hydrochloride, ammonium chloride and bismuth nitrate were mixed according to a mass ratio of 1:0.7:0.15, and then high-energy ball milling was performed for 30 minutes to obtain powder. The ball milling speed during high-energy ball milling in this embodiment 200 r / min, the ball-to-material ratio is 10:1, and the ball filling coefficient is 7%; then the mixture obtained by high-energy ball milling is moved into a closed alumina crucible, placed in a muffle furnace with air, and heated at 7°C / min to 550°C, calcined for 2.5 hours, and cooled to room temperature to obtain BiOCl / g-C 3 N 4 Layered heterojunction photocatalysts. The catalyst has a specific surface area of 102 m 2 / g.

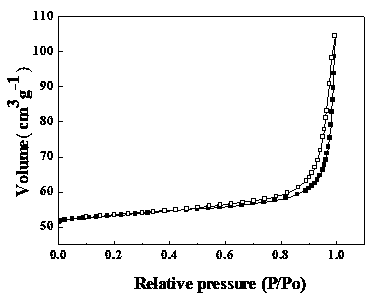

[0035] Depend on figure 1 It can be seen that through the detection of nitrogen adsorption-desorption technology, it is found that in the range of relative pressure (P / Po) = 0.5-1.0, a hysteresis loop appears on the is...

Embodiment 2

[0044] Under the atmosphere of nitrogen gas in a closed container, guanidine hydrochloride, ammonium chloride and bismuth nitrate were mixed according to the mass ratio of 1:1:0.2, and then high-energy ball milling was performed for 60 minutes to obtain powder. The ball milling speed during the high-energy ball milling process was 180 rev / min, the ball-to-material ratio is 8:1, and the ball filling coefficient is 5%; then the mixture is moved into a closed alumina crucible, placed in a muffle furnace, and heated to 500°C at 3°C / min. Roasting for 3 hours, down to room temperature, to obtain BiOCl / g-C 3 N 4 Layered heterojunction photocatalysts. The catalyst has a specific surface area of 96 m 2 / g.

[0045] Evaluation conditions: In the waste water of 20 mg / L tetracycline hydrochloride and 20 mg / L cephradine, the mass of catalyst added is 0.6 mg / mL based on the volume of waste water, and the wavelength in the range of 420-800 nm Under the irradiation of light source, the ...

Embodiment 3

[0048] Under the atmosphere of nitrogen gas in a closed container, guanidine hydrochloride, ammonium chloride and bismuth nitrate were mixed according to the mass ratio of 1:0.5:0.1, and then high-energy ball milling was performed for 20 minutes to obtain powder. The ball milling speed during the high-energy ball milling process was 250 rpm, the ball-to-material ratio is 15:1, and the ball filling factor is 9%; then the mixture is moved into a closed alumina crucible, placed in a muffle furnace with air, and the temperature is raised to 650°C at 10°C / min. Calcined for 2.0 hours, down to room temperature, to obtain BiOCl / g-C 3 N 4 Layered heterojunction photocatalysts. The catalyst has a specific surface area of 90 m 2 / g.

[0049] Evaluation conditions: In 40 mg / L wastewater containing cephradine, the amount of catalyst added is 1.5 mg / mL based on the volume of wastewater, under the irradiation of a light source with a wavelength of 420-800 nm, the reaction is stirred at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface | aaaaa | aaaaa |

| Specific surface | aaaaa | aaaaa |

| Specific surface | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com