Manufacturing method for silicon nitride coating

A technology of silicon nitride coating and manufacturing method, applied in chemical instruments and methods, coating, crystal growth, etc., can solve the problems of reducing the quality of silicon wafers, increasing the manufacturing cost of silicon wafers, and contamination of the bottom and side of silicon ingots , to achieve the effect of reducing production cost, improving product quality, and avoiding the phenomenon of sticking pot

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

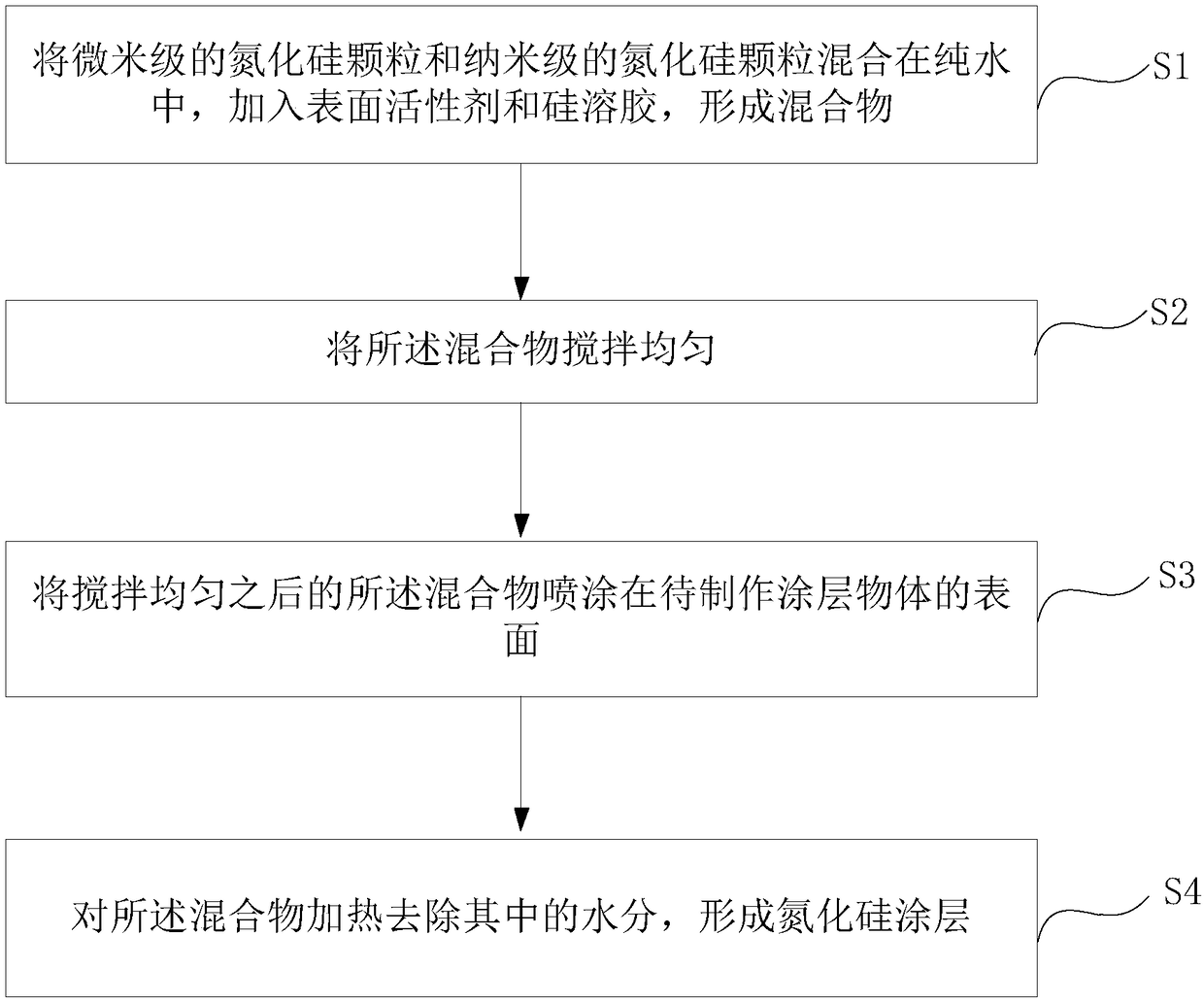

Method used

Image

Examples

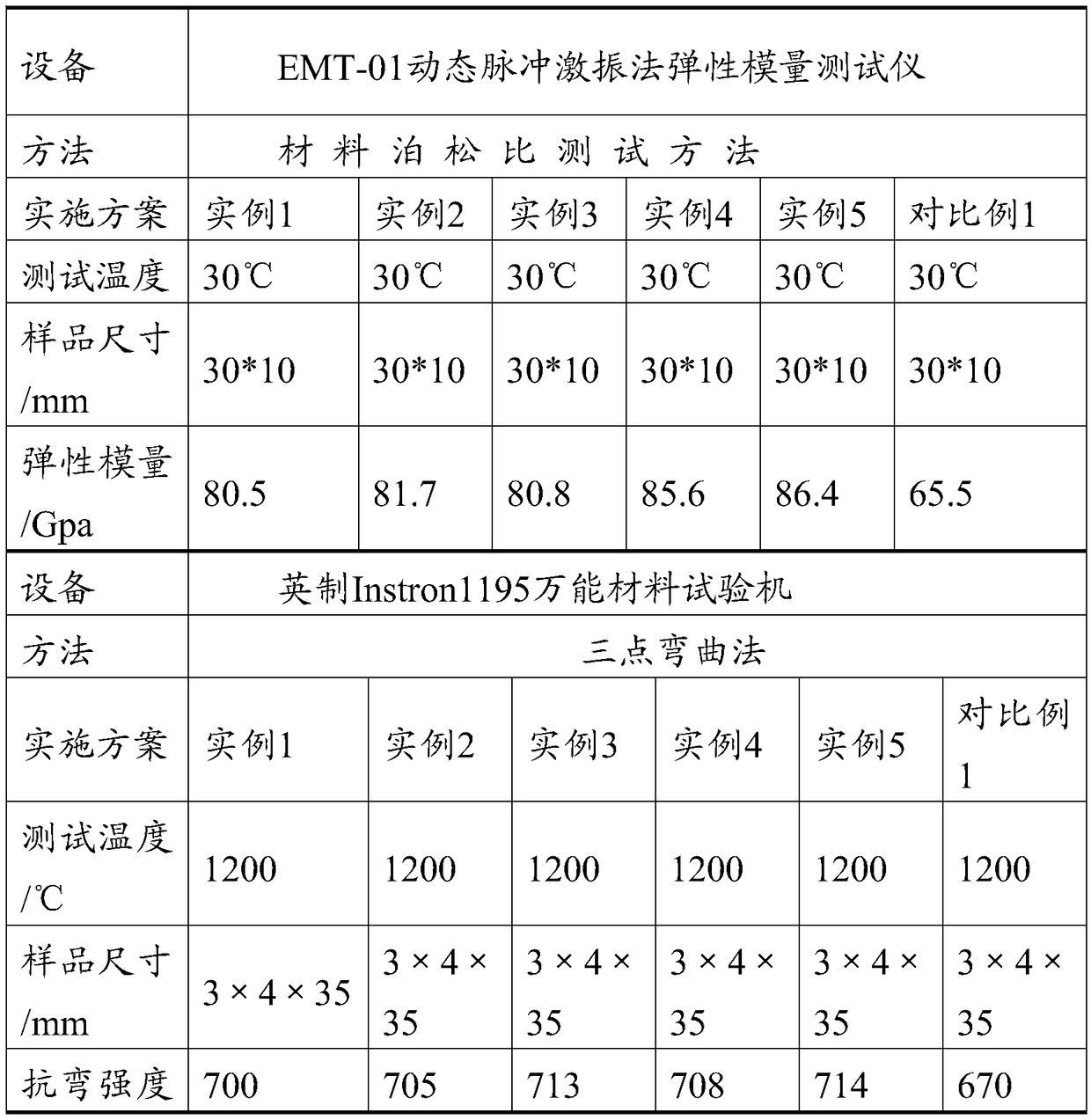

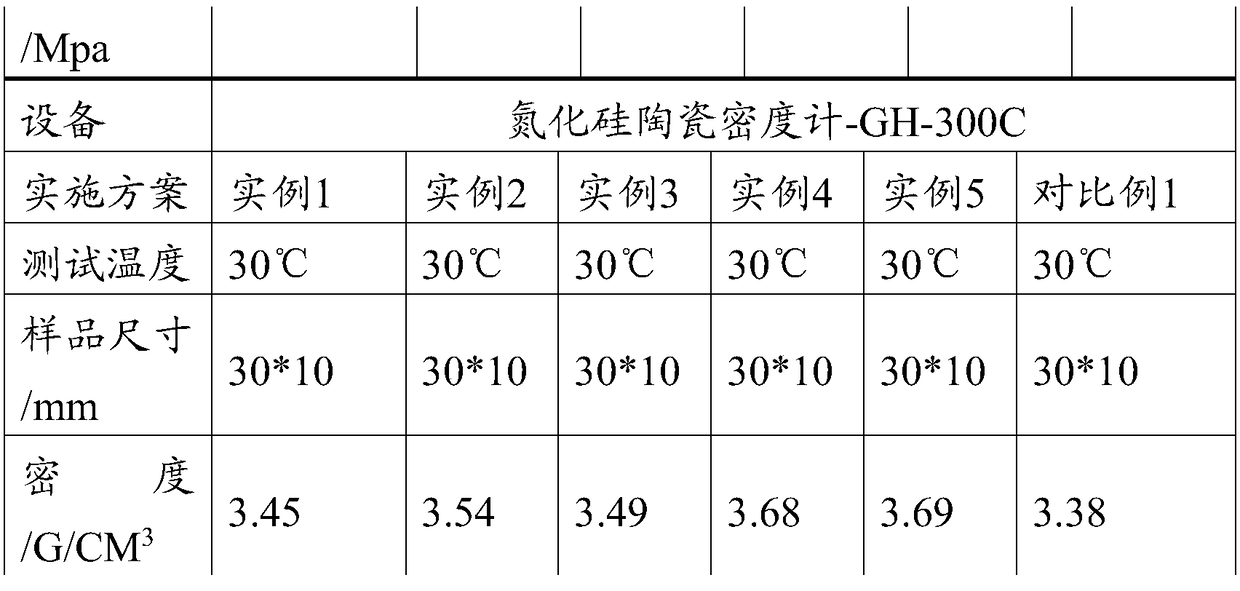

example 1

[0047] [Example 1] Weigh 650g of silicon nitride powder with D50 (50% average particle size, the same below) of 2.5um, 50g of silicon nitride powder with D50 of 1.5nm, and measure 2300ml with a graduated cylinder. Water, measure 300ml of ion-free silica sol and 5g fatty alcohol polyoxyethylene ether (AEO) with a graduated cylinder, then mix the above materials into a graduated cylinder containing a stirrer, stir quickly for 3 minutes, and continue stirring at a medium speed at 220rpm 5 minutes;

[0048] Remove the quartz crucible package and place it flat on the bottom of the high-purity isocratic graphite. Turn on the crucible and heat the rotating table. Use the infrared tester to test the temperature of the crucible inner wall to 100 degrees Celsius. Then spray the silicon nitride on the inner wall area of the crucible. After spraying the silicon nitride slurry, heat it on the crucible heating rotary table for 30 minutes to ensure that the water in the crucible inner wall co...

example 2

[0049] [Example 2] Weigh 700g of silicon nitride powder with D50 of 2.75um, 65g of silicon nitride powder with D50 of 0.75nm, measure 2700ml of pure water with a graduated cylinder, and measure 300ml of ion-free silica sol with a graduated cylinder. , 7g fatty alcohol polyoxyethylene ether (AEO), then mix the above materials into a graduated cylinder containing a stirrer, stir quickly for 4 minutes, and continue stirring at medium speed for 5 minutes at 250rpm;

[0050] Remove the quartz crucible package and place it flat on the bottom of the high-purity isocratic graphite. Turn on the crucible and heat the rotating table. Use the infrared tester to test the temperature of the crucible inner wall to 100 degrees Celsius. Then spray the silicon nitride on the inner wall area of the crucible. After spraying the silicon nitride slurry, heat it on the crucible heating rotary table for 30 minutes to ensure that the water in the crucible inner wall coating is fully evaporated. Finally,...

example 3

[0051] [Example 3] Weigh 730g of silicon nitride powder with D50 of 2.05um, 55g of silicon nitride powder with D50 of 0.95nm by electronic weighing, measure 3000ml of deionized water with a graduated cylinder, and measure 350ml of non-ionized silicon with a graduated cylinder Sol, 7.5g fatty alcohol polyoxyethylene ether (AEO), then mix the above materials into a graduated cylinder containing a stirrer, stir quickly for 4 minutes, and continue stirring at medium speed for 5 minutes at 250rpm;

[0052] Remove the quartz crucible package and place it flat on the bottom of the high-purity isocratic graphite. Turn on the crucible and heat the rotating table. Use the infrared tester to test the temperature of the crucible inner wall to 100 degrees Celsius. Then spray the silicon nitride on the inner wall area of the crucible. After spraying the silicon nitride slurry, heat it on the crucible heating rotary table for 30 minutes to ensure that the water in the crucible inner wall coati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com