Antistatic low-smoke halogen-free flame-retardant PC/ABS alloy material and preparation process thereof

An alloy material and anti-static technology, applied in the field of functional plastic alloy materials, can solve the problems of producing toxic corrosive gas and large amount of smoke, and achieve improved smoke suppression effect, good thermal stability and good mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

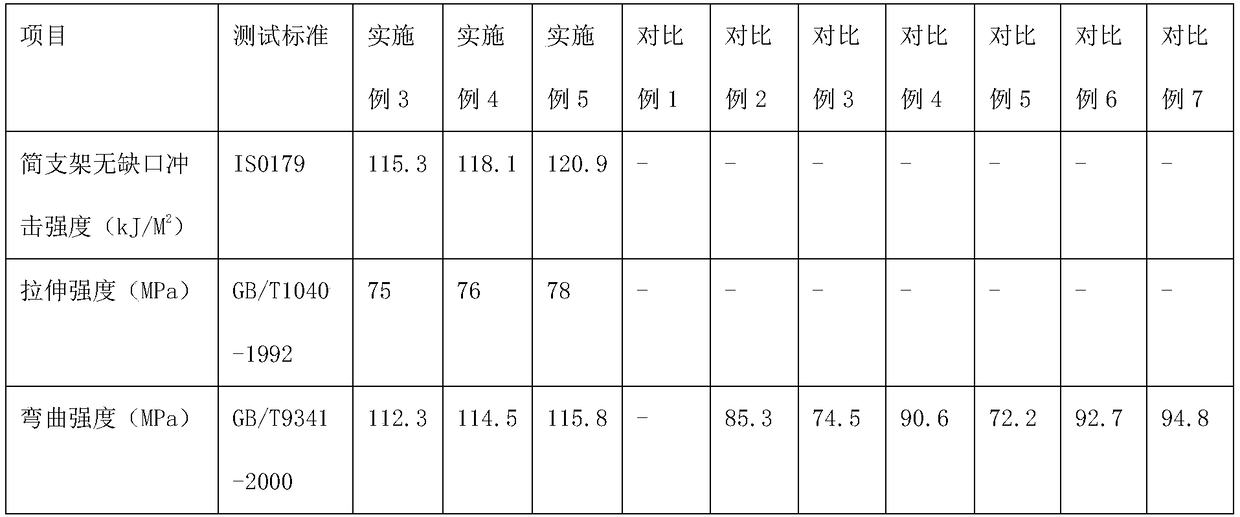

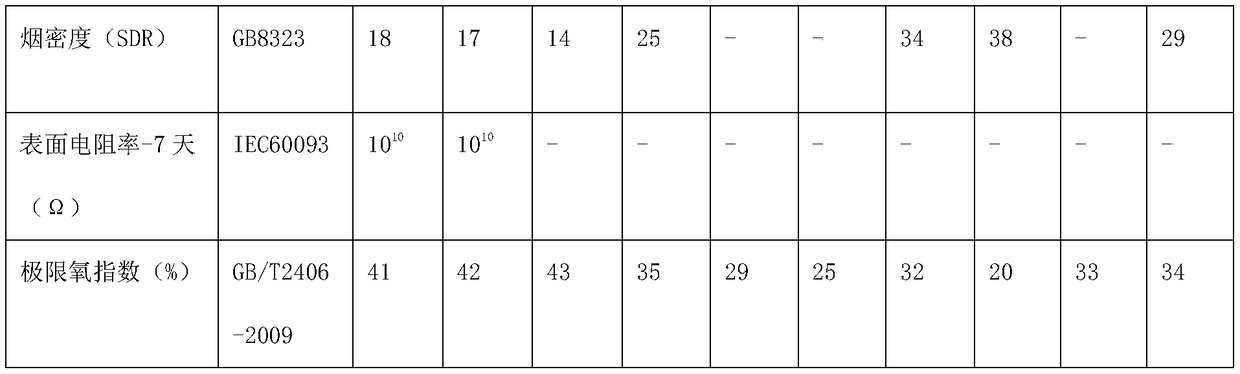

Examples

Embodiment 1

[0036]Weigh 60kgPC, 48kgABS, 0.5kg nano-sized magnesium hydroxide, 0.5kg alkylsulfonate, 1kg aminoacrylonitrile-styrene copolymer, 0.5kg isopropyl tris(dodecylbenzenesulfonyl) titanic acid Put ester, 0.5kg vinylbisstearamide and 0.5kg tris(2,4-di-tert-butylphenyl) phosphite into the high-speed mixer, stir at room temperature for 10min; the mixed material is added into the In the twin-screw extruder, it undergoes melt blending extrusion, water cooling, air knife cooling, granulation, and homogenization. Among them, the temperature of the barrel is set as follows: the rear section is 230°C, the middle section is 220°C, the front section is 210°C, the length-to-diameter ratio of the screw is 35, and the screw speed is 350r / min.

Embodiment 2

[0038] Weigh 85kgPC, 60kgABS, 2kg nano-sized magnesium hydroxide, 2kg alkylsulfonate, 4kg maleic anhydride grafted linear low density polyethylene, 1kg isopropyl tris(dodecylbenzenesulfonyl) titanate, Put 1kg of montan wax and 1kg of tris(2,4-di-tert-butylphenyl)phosphite into a high-speed mixer, and stir for 20min at room temperature; Melt blending extrusion, water cooling, air knife cooling, granulation, homogenization. Among them, the temperature of the barrel is set as follows: the rear section is 250°C, the middle section is 240°C, the front section is 230°C, the length-to-diameter ratio of the screw is 40, and the screw speed is 500r / min.

Embodiment 3

[0040] Weigh 70kgPC, 53kgABS, 0.1kg nanoscale aluminum hydroxide, 0.16kg nanoscale zirconia, 1kg alkyl sulfonate, 2.5kg aminoacrylonitrile-styrene copolymer, 0.7kg isopropyl tri(dodecane phenylsulfonyl) titanate was put into a high-speed mixer, and stirred at room temperature for 5 minutes; Sonicate for 5-10 minutes, take it out and dry it before use), 0.16kg ammonium nonamolybdenum manganate, 0.6kg vinylbisstearamide and 0.6kg tris(2,4-di-tert-butylphenyl) phosphite, at room temperature Stir at low temperature for 10 minutes; the mixed material is fed into the twin-screw extruder from the hopper, melted and blended, extruded, water-cooled, air-knife cooled, granulated, and homogenized. Among them, the temperature of the barrel is set as follows: the rear section is 240°C, the middle section is 230°C, the front section is 220°C, the length-to-diameter ratio of the screw is 37, and the screw speed is 400r / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com