Upconversion magnetically-coded microspheres for mycotoxin flux detection and preparation method thereof

A mycotoxin and magnetic encoding technology, which is applied in the direction of microsphere preparation, microcapsule preparation, measuring device, etc., can solve the problems of increased health hazard coefficient, shortened analysis time, accumulation of mycotoxin, etc., and achieves stable optical properties and fluorescent background Low, high signal-to-noise ratio effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

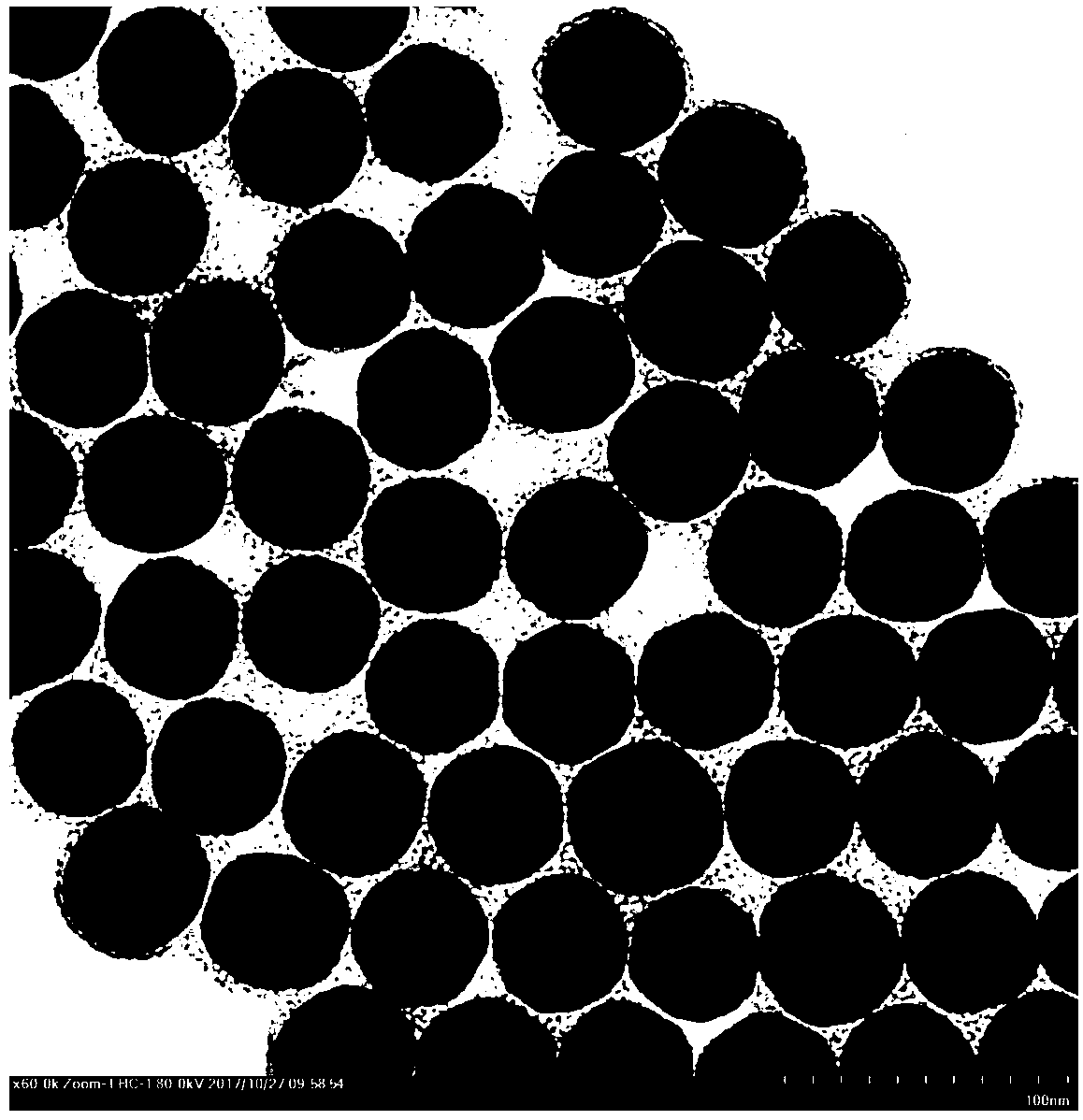

[0111] (1) The synthesis steps of up-conversion nanoparticles are as follows:

[0112] 1) Up-conversion nanoparticles are prepared by solvothermal method: according to the mass ratio of yttrium chloride: ytterbium chloride: erbium chloride = 80:20:2, the rare earth solution is added to the reaction vessel, the heating temperature is set to 100°C and Stir until a white solid appears;

[0113] 2) After the water is completely evaporated to dryness, turn off the heating and cool to 50°C, add 5ml of oleic acid and 12ml of octadecene, and raise the temperature to 150°C to completely dissolve the white solid;

[0114] 3) Cool to 50°C, dissolve 0.1g of sodium hydroxide and 0.16g of ammonium fluoride in methanol solution, and add them into the rare earth reaction vessel; raise the temperature to 120°C, and vacuumize for 20 minutes with an oil pump;

[0115] 4) heating up to 280°C, stirring and reacting for 60 minutes;

[0116] 5) After the reaction is completed, alcohol is added for...

Embodiment 2

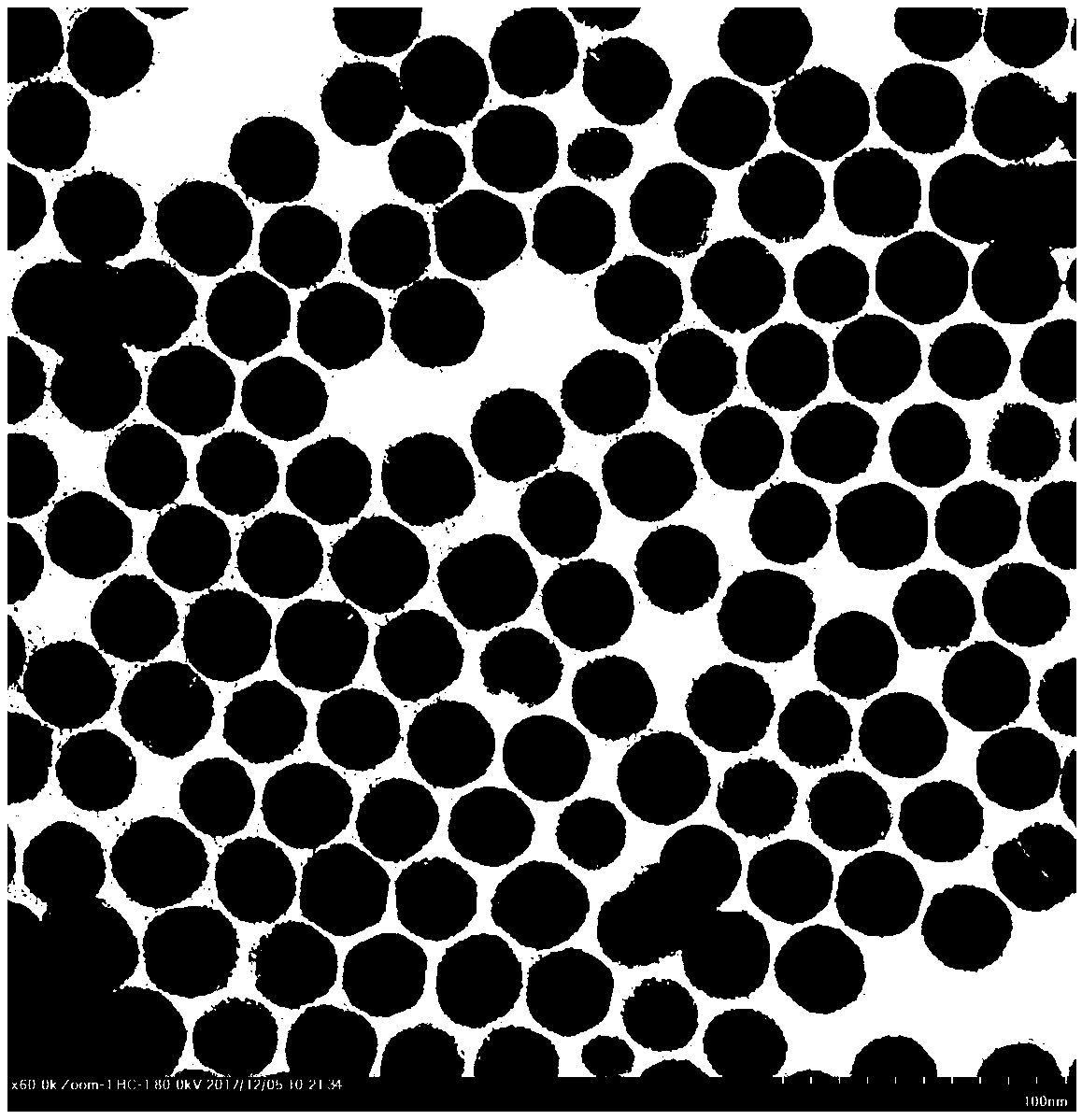

[0124] (1) The synthesis steps of up-conversion nanoparticles are as follows:

[0125] 1) The up-conversion nanoparticles are prepared by solvothermal method: according to the mass ratio of yttrium chloride: ytterbium chloride: thulium chloride = 75:20:2, the rare earth solution is added to the reaction vessel, the heating temperature is set to 110°C and Stir until a white solid appears;

[0126] 2) After the water is completely evaporated to dryness, turn off the heating and cool to 50°C, add 6ml of oleic acid and 12ml of octadecene, and raise the temperature to 130°C to completely dissolve the white solid;

[0127] 3) Cool to 50°C, dissolve 0.1g of sodium hydroxide and 0.15g of ammonium fluoride in methanol solution, and add them into the rare earth reaction vessel; raise the temperature to 120°C, and use an oil pump to evacuate for 30 minutes;

[0128] 4) heating up to 280°C, stirring and reacting for 60 minutes;

[0129] 5) After the reaction is completed, alcohol is add...

Embodiment 3

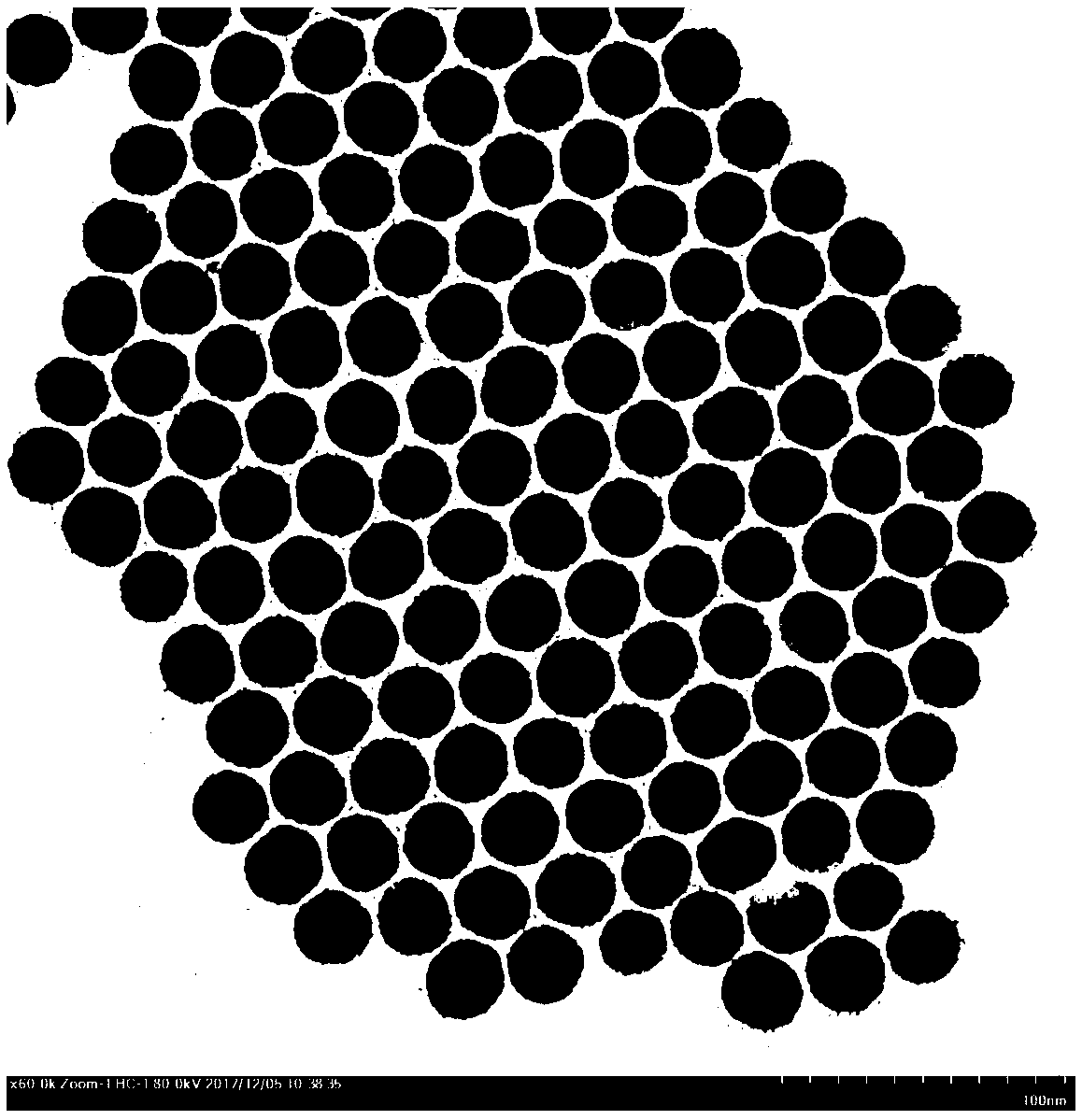

[0137] (1) The synthesis steps of up-conversion nanoparticles are as follows:

[0138] 1) The up-conversion nanoparticles are prepared by solvothermal method, which is an ABA three-layer structure: according to the mass ratio of yttrium chloride: ytterbium chloride: thulium chloride = 80:20:2, the rare earth solution is added to the reaction vessel, and the Heat the temperature to 110°C and stir until a white solid appears;

[0139] 2) After the water is completely evaporated to dryness, turn off the heating and cool to 40°C, add 4ml of oleic acid and 10ml of octadecene, and raise the temperature to 150°C to completely dissolve the white solid;

[0140] 3) Cool to 40°C, dissolve 0.15g of sodium hydroxide and 0.2g of ammonium fluoride in methanol solution, and add them into the rare earth reaction vessel; raise the temperature to 150°C, and vacuumize for 30 minutes with an oil pump;

[0141] 4) heating up to 270°C, stirring and reacting for 60 minutes;

[0142] 5) After the r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com