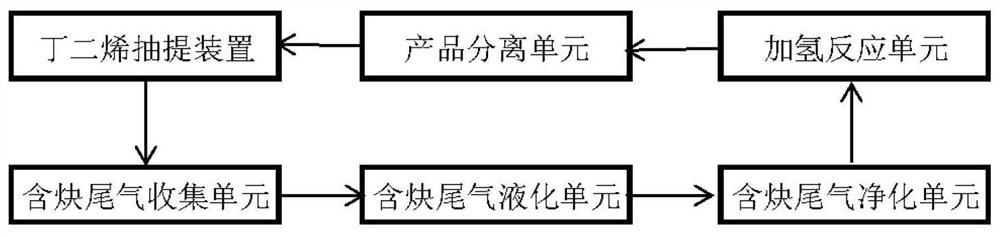

A kind of alkyne selective hydrogenation catalyst and its preparation method and application

A hydrogenation catalyst and selective technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., can solve the problem of reducing catalyst activity, selectivity and stability, There are many side reactions, poor hydrogenation activity stability and other problems, so as to improve the hydrogenation selectivity and operation stability, the preparation method is simple and easy to operate, and the operation stability is excellent.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

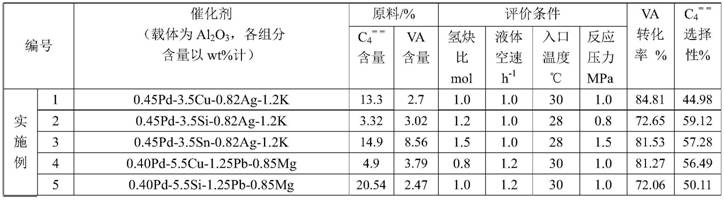

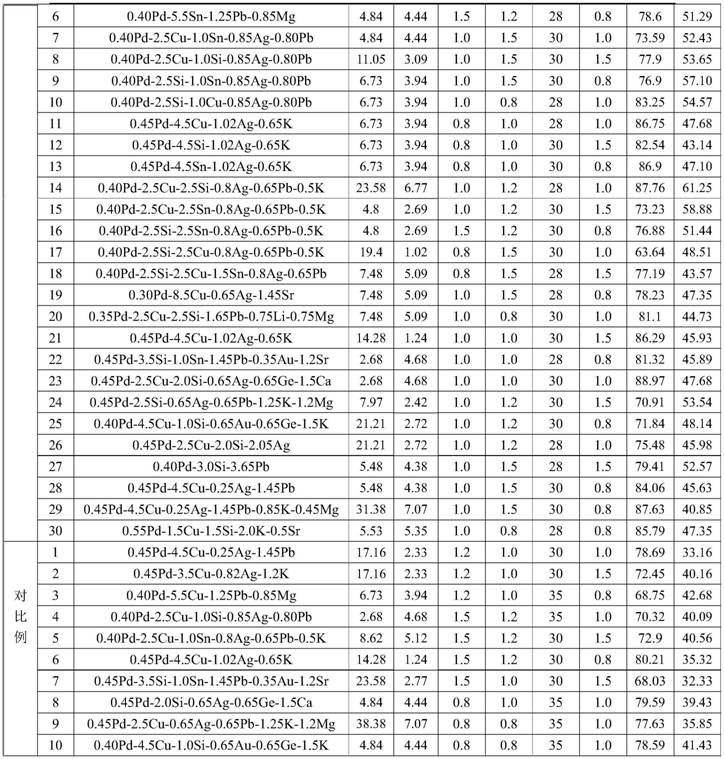

Embodiment 1-10

[0048] The alkyne selective hydrogenation catalyst carrier of embodiment 1~10 is Al 2 o 3 , each component is as shown in table 1, and its preparation process is:

[0049] A. Carrier preparation:

[0050] The preparation concentration is 200gAl 2 o 3 / L Sodium metaaluminate solution 1L, heated to 70°C, the prepared concentration is 80gAl 2 o 3 / L aluminum sulfate solution 2L, heated to 70°C;

[0051] Add 1.0L of distilled water to the gelling tank, heat it to 70°C, and add the above two slurries at the same time, keep the pH value at 8.0, and carry out gelling at a temperature of 70°C. During the gelling process, add Cu salt with a concentration of 0.05mol / L solution and / or Sn salt solution and / or Si salt solution;

[0052] After gel formation, aging at pH 8.0 and temperature 70°C for 60 minutes. After aging, inject deionized water at 65°C, beat, wash, and filter the aged slurry at a stirring rate of 200rpm, and dry the filter cake at 100°C for 3 hours to obtain a pseu...

Embodiment 11-20

[0058] The alkyne selective hydrogenation catalyst carrier of embodiment 11~20 is Al 2 o 3 , each component is as shown in table 1, and its preparation process is:

[0059] A. Carrier preparation:

[0060] Prepare the concentration of 200gAl in the gel tank 2 o 3 / L aluminum nitrate solution 1L, the preparation concentration is 80gAl 2 o 3 / L aluminum sulfate solution 1L, mix well and heat to 75°C;

[0061] Inject CO into the glue tank 2 Gas, maintain a pH value of 8.0 to 8.5, and perform gelation at a temperature of 75°C. After gelation, age at a pH value of 8.0 and a temperature of 70°C for 60 minutes;

[0062] After aging, inject deionized water at 75°C, beat at a stirring rate of 200rpm after washing, and add Cu salt solution and / or Sn salt solution and / or Si salt solution with a concentration of 0.05mol / L at the same time, beat for 60min and then filter. After the filter cake was dried at 120° C. for 8 hours, pseudo-boehmite containing Cu and / or Sn and / or Si was o...

Embodiment 21-30

[0068] Alkyne selective hydrogenation catalyst carrier of embodiment 21~30 is Al 2 o 3 , each component is as shown in table 1, and its preparation process is:

[0069] A. Carrier preparation:

[0070] The preparation concentration is 200gAl 2 o 3 / L aluminum nitrate solution 1L, the preparation concentration is 80gAl 2 o 3 / L aluminum sulfate solution 1L, mix the two solutions and heat to 50°C;

[0071] Prepare a mixed solution of sodium carbonate and ammonium bicarbonate in the gelling tank and heat it to 60°C, add the mixed solution of aluminum nitrate and aluminum sulfate into the gelling tank, keep the pH value at 8.0-8.5, and gel at a temperature of 60°C , adding a Cu salt solution and / or a Sn salt solution and / or a Si salt solution with a concentration of 0.05mol / L during the gelling process;

[0072] After gel formation, aging at pH 8.0 and temperature 60°C for 60 minutes. After aging, inject 75°C deionized water for washing, then beat at a stirring rate of 200...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| coking value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com