A method for preparing a one-dimensional nanomaterial-based sensor

A technology of nanomaterials and sensors, which is applied in the field of preparation of one-dimensional nanomaterial sensors, can solve the problems of one-dimensional nanomaterial arrangement dependence, complex surface modification, complex process, etc., and achieve experimental cost saving, good combination, and arrangement good consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

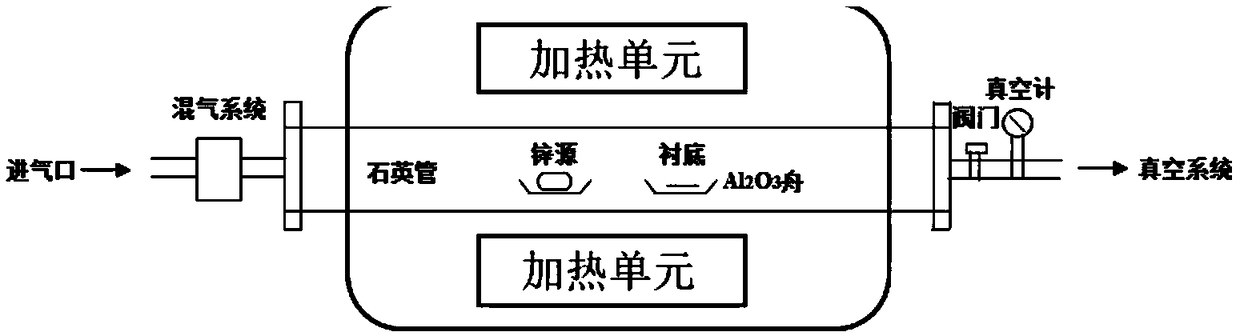

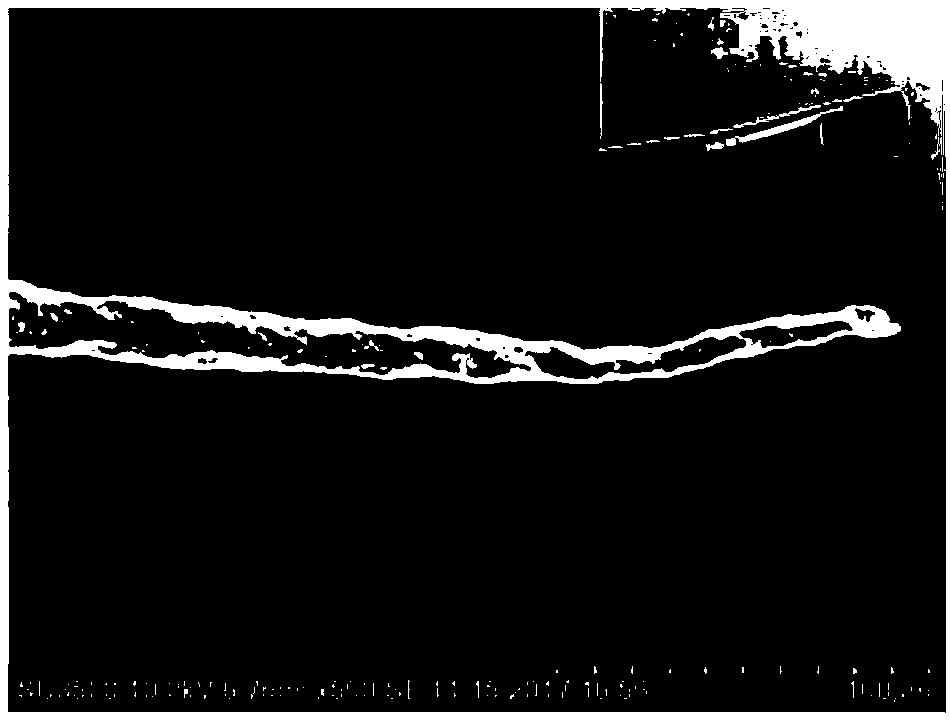

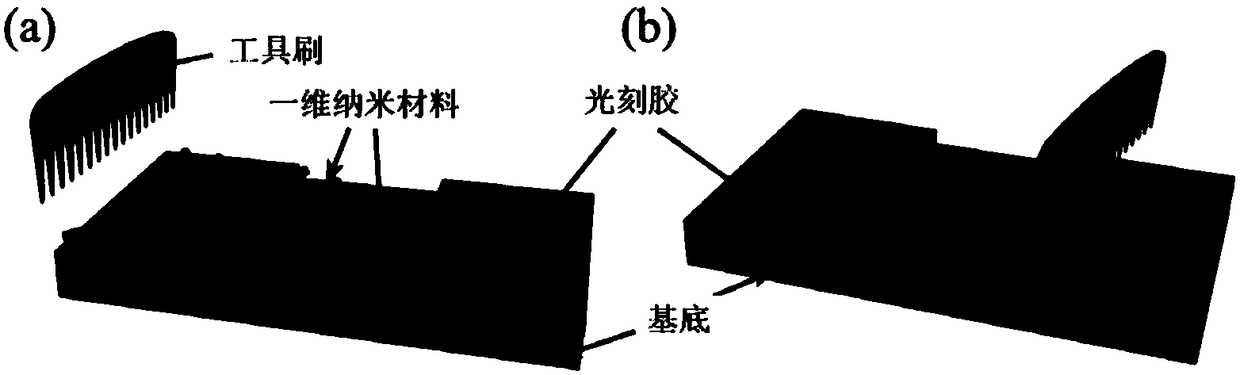

[0035] This example prepares a gas sensor based on the assembly method of zinc oxide nanowires to detect carbon monoxide, including the steps of preparing zinc oxide nanowires, the assembly steps of zinc oxide nanowires and the preparation steps of gas sensors, such as figure 1 It is a schematic diagram of the general flow of the invention;

[0036] The steps of preparing zinc oxide nanowires:

[0037] Preparation device such as figure 2As shown, the silicon wafer was cut into 2cm*2cm slices before preparation, and the silicon wafer was cleaned with ethanol, deionized water, and acetone for 5 minutes, and then placed on a hot plate to remove residual liquid. Zinc powder (purity 99.99%) was put into an alumina boat, the alumina boat was placed in the center of the quartz tube, and the substrate was placed 3-4 cm to the right of the zinc source. When the vacuum degree of the air passage is 10Pa with a mechanical pump, the temperature in the furnace is raised to 600-750°C, and...

Embodiment 2

[0058] In this embodiment, in order to verify the universality of the present invention, silicon nanowires are assembled, and the type of the substrate is changed at the same time, and a silicon substrate coated with a gold film is used.

[0059] Steps for preparing silicon nanowires:

[0060] (1) First, cut the p-type (100) direction single crystal silicon wafer into 1*1cm 2 Then immerse the silicon wafer in an ethanol solution, and perform ultrasonic cleaning in an ultrasonic cleaning tank for 10 minutes to remove surface organic matter;

[0061] (2) Put the silicon chip into the H of the configuration 2 SO 4: h 2 o 2 Ultrasonic cleaning in the solution for 10 minutes to further remove surface organic matter and form an oxide layer, and then clean the silicon wafer with 5% HF to remove the surface oxide layer;

[0062] (3) Configure different concentrations of HF-AgNO 3 Corrosion solution, placed in a 100ml reaction kettle with tetrafluoroethylene lining, the filling d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com