Preparation method of polyether sulfone separation membrane with polyaminocarboxylic acid group

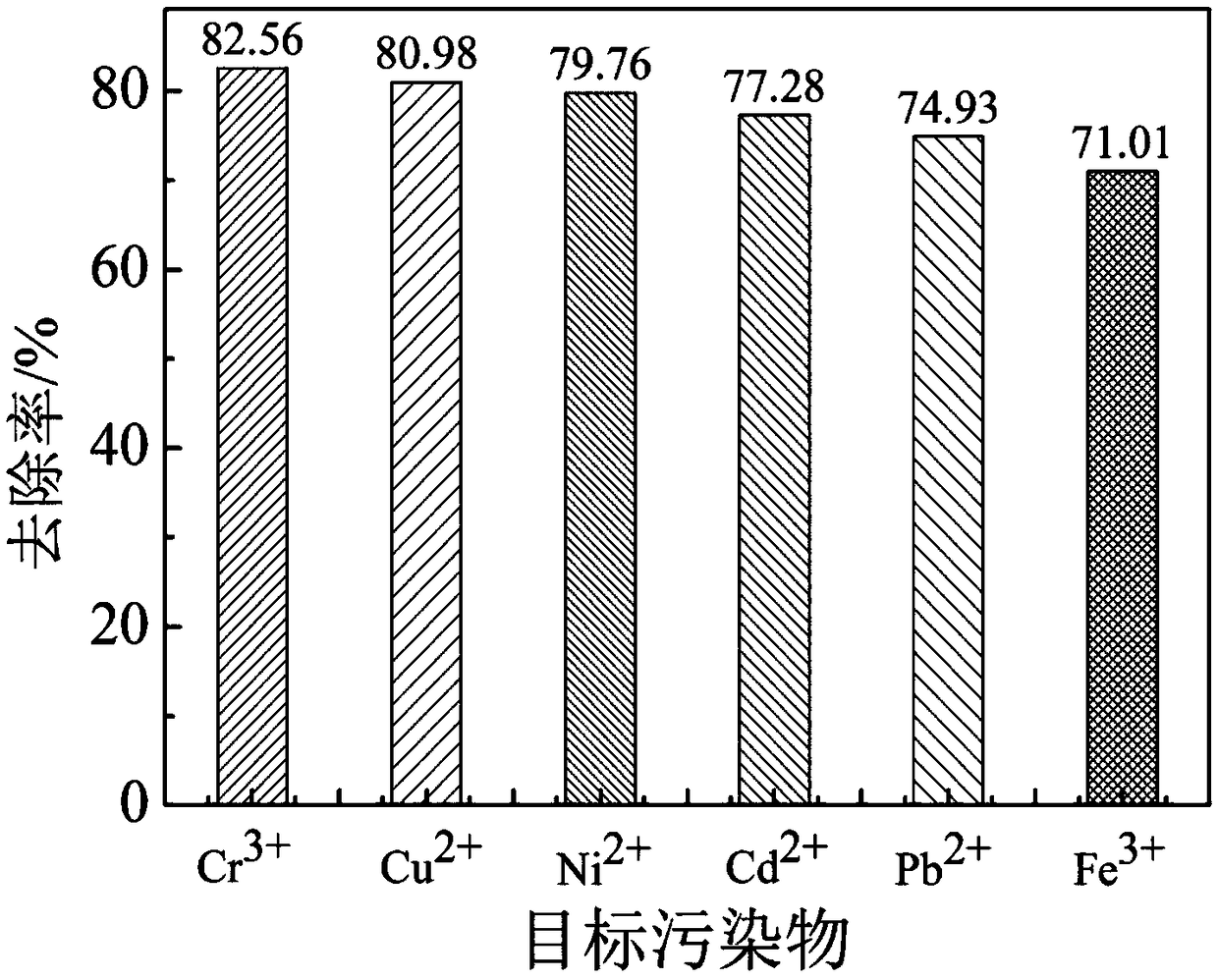

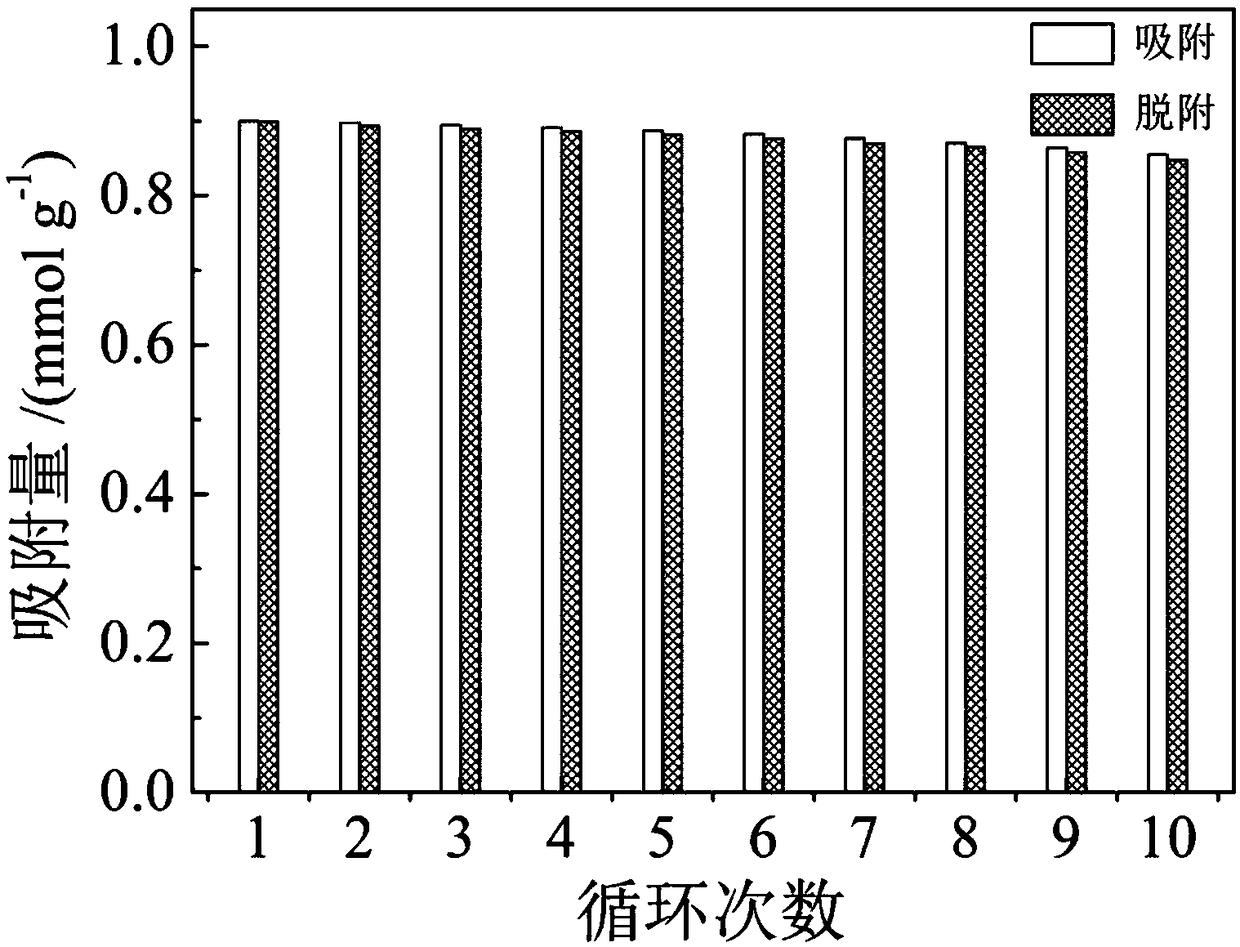

A polyaminocarboxylic acid and polyaminocarboxylic acid functional technology, which is used in semi-permeable membrane separation, chemical instruments and methods, membrane technology, etc., can solve the problem that the adsorption performance of heavy metals needs to be improved, the adsorption and removal effect is limited, and the phosphonation efficiency is low. problem, to achieve the effect of excellent adsorption and removal efficiency, not easy to leaching loss, not easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] First, pour 110g of chloroform into a three-necked round-bottomed flask, then add 8g of polyethersulfone powder, then fix the three-necked round-bottomed flask on a magnetic stirrer, connect one side of the three-necked round-bottomed flask to a nitrogen conduit, and the other side The mouth is connected to an absorption tube filled with granular activated carbon to absorb volatilized chloroform. The central mouth of the three-neck round bottom flask is sealed with a ground glass stopper. First, slowly adjust the speed of the stirrer to 200r / min, and stir magnetically for 30min. After the powdered polyether When the sulfone becomes a fluffy block, adjust the rotation speed to 550r / min, and continue magnetically stirring the solution at room temperature until the fluffy block polyethersulfone is completely dissolved in chloroform; after that, slowly inject nitrogen gas into the three-hole round bottom In the polyethersulfone chloroform solution in the flask, the flow rate...

Embodiment 2

[0053] First, pour 112g of chloroform into a three-necked round-bottomed flask, then add 8g of polyethersulfone powder, then fix the three-necked round-bottomed flask on a magnetic stirrer, connect one side of the three-necked round-bottomed flask to a nitrogen conduit, and the other side The mouth is connected to an absorption tube filled with granular activated carbon to absorb volatilized chloroform. The central mouth of the three-neck round bottom flask is sealed with a ground glass stopper. First, slowly adjust the speed of the stirrer to 200r / min, and stir magnetically for 30min. After the powdered polyether When the sulfone becomes a fluffy block, adjust the rotation speed to 550r / min, and continue magnetically stirring the solution at room temperature until the fluffy block polyethersulfone is completely dissolved in chloroform; after that, slowly inject nitrogen gas into the three-hole round bottom In the polyethersulfone chloroform solution in the flask, the flow rate...

Embodiment 3

[0063] First, pour 114g of chloroform into a three-necked round-bottomed flask, then add 8g of polyethersulfone powder, then fix the three-necked round-bottomed flask on a magnetic stirrer, connect one side of the three-necked round-bottomed flask to a nitrogen conduit, and the other side The mouth is connected to an absorption tube filled with granular activated carbon to absorb volatilized chloroform. The central mouth of the three-neck round bottom flask is sealed with a ground glass stopper. First, slowly adjust the speed of the stirrer to 200r / min, and stir magnetically for 30min. After the powdered polyether When the sulfone becomes a fluffy block, adjust the rotation speed to 550r / min, and continue magnetically stirring the solution at room temperature until the fluffy block polyethersulfone is completely dissolved in chloroform; after that, slowly inject nitrogen gas into the three-hole round bottom In the polyethersulfone chloroform solution in the flask, the flow rate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com