High-strength adhesive for pencil production

A high-strength, adhesive technology, applied in the direction of adhesives, adhesive additives, polymer adhesive additives, etc., can solve the problems of cold resistance, water resistance, heat resistance, poor mechanical strength, long-term preservation and stability The application of the pencil, the high scrap rate of pencils, etc., achieve the effect of optimizing the organizational structure, improving the compatibility and bonding strength, and improving the stability of the particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

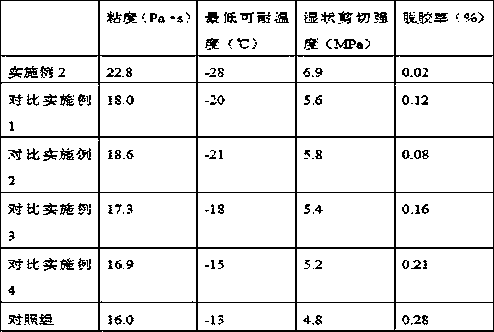

Examples

Embodiment 1

[0024] A high-strength adhesive for pencil production, made of the following materials in parts by weight:

[0025] 50 parts of vinyl acetate, 15 parts of terpene resin, 5 parts of C9 petroleum resin, 3 parts of butyl benzyl phthalate, 5 parts of polyethylene glycol, 1 part of sodium dodecylbenzene sulfonate, 1 part of hexadecimal Sodium phosphate, 0.15 parts of ammonium persulfate, 0.3 parts of sodium bicarbonate, 8 parts of ethyl acetate, 3 parts of corn fiber gum, 0.5 parts of chitosan, 0.1 part of antioxidant, 4 parts of functional fillers, 70 parts of deionized water.

[0026] Further, the antioxidant is antioxidant 168.

[0027] Further, the preparation method of the functional filler comprises the following steps:

[0028] (1) Wash and pulverize the corn stalks first, and make corn stalk particles with a particle diameter not greater than 2cm for later use;

[0029] (2) Put the corn stalk granules obtained in step (1) into boiling water and boil for 20 minutes, then r...

Embodiment 2

[0038] A high-strength adhesive for pencil production, made of the following materials in parts by weight:

[0039] 50~55 parts of vinyl acetate, 15~20 parts of terpene resin, 5~8 parts of C9 petroleum resin, 3~6 parts of butyl benzyl phthalate, 5~7 parts of polyethylene glycol, 1~3 parts of ten Sodium dialkylbenzenesulfonate, 1~3 parts of sodium hexametaphosphate, 0.15~0.18 parts of ammonium persulfate, 0.3~0.5 parts of sodium bicarbonate, 8~12 parts of ethyl acetate, 3~5 parts of corn fiber gum, 0.5 ~1 part chitosan, 0.1~0.2 parts antioxidant, 4~6 parts functional filler, 70~80 parts deionized water.

[0040] Further, the antioxidant is Antioxidant 300.

[0041] Further, the preparation method of the functional filler comprises the following steps:

[0042] (1) Wash and pulverize the corn stalks first, and make corn stalk particles with a particle diameter not greater than 2cm for later use;

[0043] (2) Put the corn stalk granules obtained in step (1) into boiling water ...

Embodiment 3

[0052] A high-strength adhesive for pencil production, made of the following materials in parts by weight:

[0053] 55 parts of vinyl acetate, 20 parts of terpene resin, 8 parts of C9 petroleum resin, 6 parts of butyl benzyl phthalate, 7 parts of polyethylene glycol, 3 parts of sodium dodecylbenzene sulfonate, 3 parts of hexadecimal Sodium phosphate, 0.18 parts of ammonium persulfate, 0.5 parts of sodium bicarbonate, 12 parts of ethyl acetate, 5 parts of corn fiber gum, 1 part of chitosan, 0.2 parts of antioxidant, 6 parts of functional fillers, 80 parts of deionized water.

[0054] Further, the antioxidant is antioxidant 1010.

[0055] Further, the preparation method of the functional filler comprises the following steps:

[0056] (1) Wash and pulverize the corn stalks first, and make corn stalk particles with a particle diameter not greater than 2cm for later use;

[0057] (2) Put the corn stalk granules obtained in step (1) into boiling water for 25 minutes, and then take...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com