Desert greening method

A desert and sandy land technology, applied in chemical instruments and methods, soil preparation methods, climate change adaptation, etc., can solve problems such as unsatisfactory, high greening effect of dead seedlings, difficult vegetation survival, etc., to ensure respiration and prevent excessive boredom The effect of oxygen environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0083] Embodiment 1: Composition and preparation of sand-fixing agent

[0084] In terms of parts by weight, the raw material components include: 62 parts of the first material, 21 parts of the second material, 1 part of microorganism liquid, 15 parts of bentonite, 5 parts of sawdust, 8 parts of waste paper pulp and 240 parts of water.

[0085] Specifically, the first material is mainly composed of the following components:

[0086] 4 parts of polyvinyl alcohol, 4 parts of styrene, 5 parts of methyl methacrylate, 5 parts of butyl acrylate, 7 parts of ethyl acrylate, 7 parts of methyl acrylate, 3 parts of acrylic acid, 2 parts of methacrylic acid, 4 parts of acrylamide 1 part, 1 part of sodium styrene sulfonate, 1 part of sodium vinyl sulfonate, 2 parts of allyloxy nonylphenol polyoxyethylene ether ammonium sulfate, 1 part of allyloxy hydroxypropyl sulfonate, 1 part of methacrylic acid hydroxy 1 part of sodium propylsulfonate, 1.5 parts of sodium 4-enebutoxy-2-hydroxypropanesul...

Embodiment 2

[0098] Embodiment 2: Composition and preparation of improver

[0099] According to parts by weight, its raw material components include: 120 parts of diatomite, 100 parts of fly ash, 60 parts of kaolin, 100 parts of peat, 140 parts of plant straw powder, 16 parts of algae-containing carrier, 50 parts of organic fertilizer, humus 55 parts, 30 parts of zeolite powder, 25 parts of glass microspheres, 20 parts of silica powder, 25 parts of microbial bacterial liquid;

[0100] 12 parts of urea, 12 parts of monoammonium phosphate, 35 parts of traditional Chinese medicine waste residue powder, 30 parts of waste tea residue, 16 parts of fulvic acid concentrate, 50 parts of distiller's grains, 45 parts of leaf humus, 50 parts of wood chips, 250 parts of husk chaff ash, 20 parts of pine phosphorus, 60 parts of coconut bran and 35 parts of slow-release fertilizer.

[0101] Wherein, the plant stalk powder comprises the following components by weight percentage:

[0102] Corn stalk powde...

Embodiment 3

[0113] Embodiment 3: desert greening method

[0114]S31: Set a windbreak and sand-fixation area at the edge of the sandy land to be greened, and set a sand-fixation barrier in the windbreak and sand-fixation area. The sand-fixation barrier is in a closed ring shape and surrounds the sandy land to be greened to form a green area;

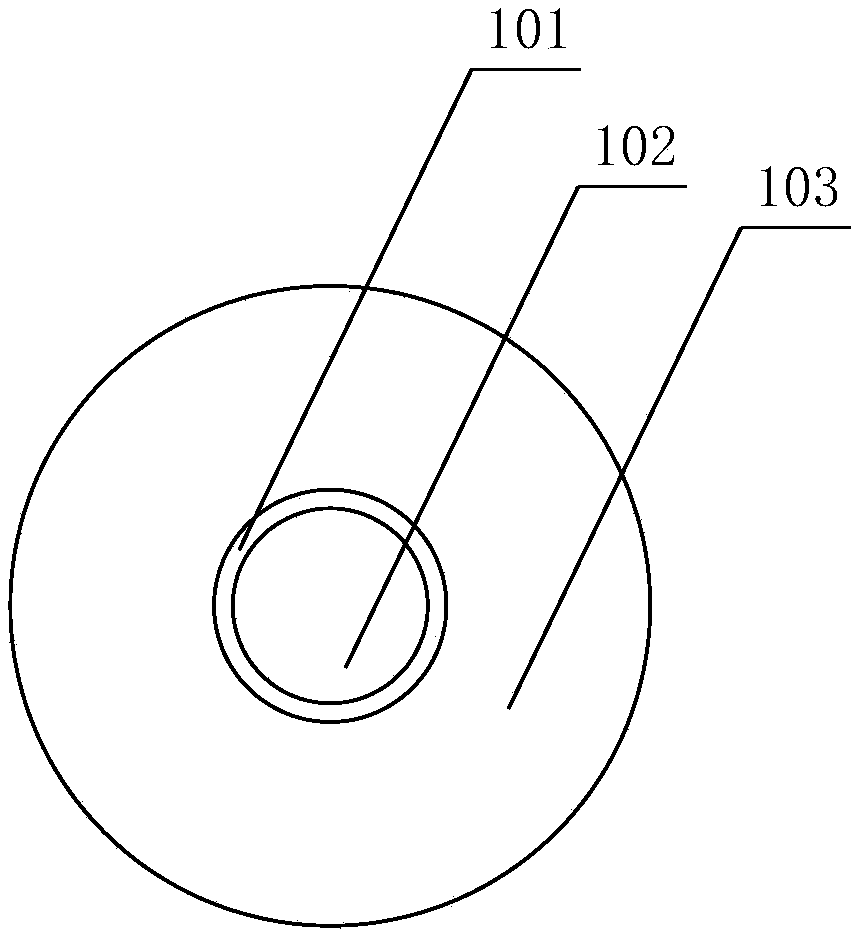

[0115] S32: Prepare the ground outside the sand-fixing barrier to form a conical slope 103 sunken toward the center, and lay cement concrete on the surface of the conical slope 103 to form a fixed smooth surface, then set an annular groove 101 at the bottom of the conical slope 103, And in the center of the annular groove 101, a water storage cellar 102 with a depth of 30 meters and a diameter of 5 meters is opened downward. The surface of the water storage cellar 102 is covered with cement concrete; holes, each water inlet hole is provided with a filter screen;

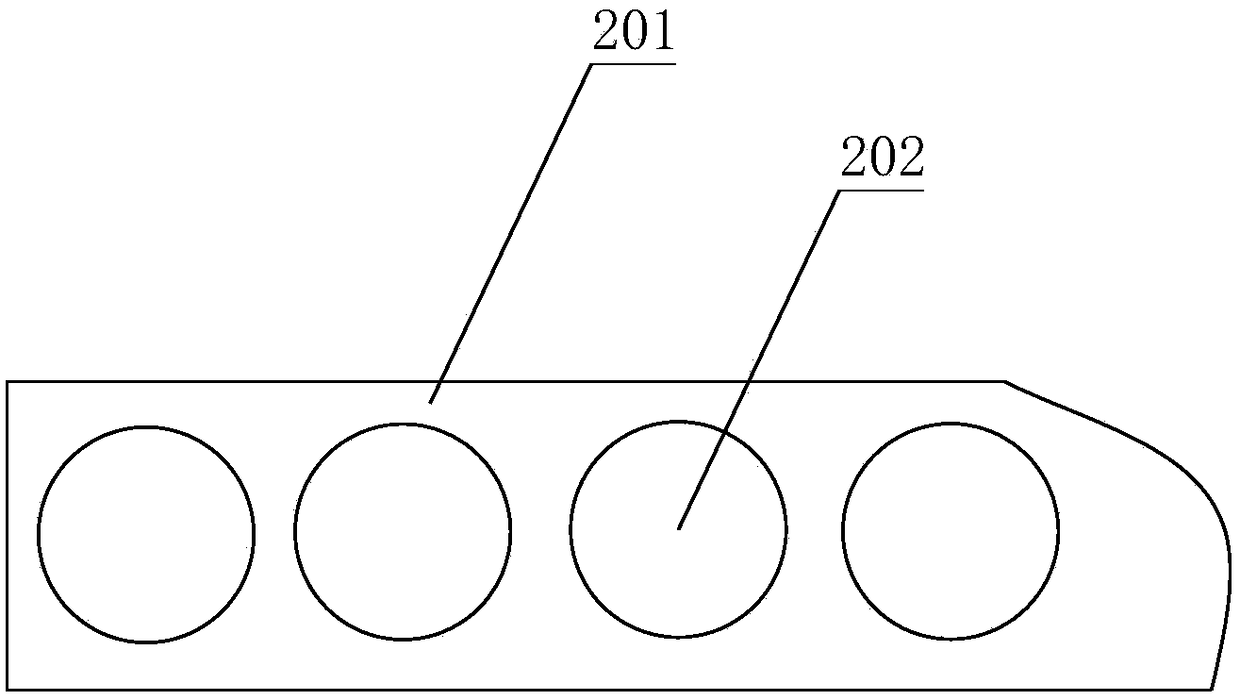

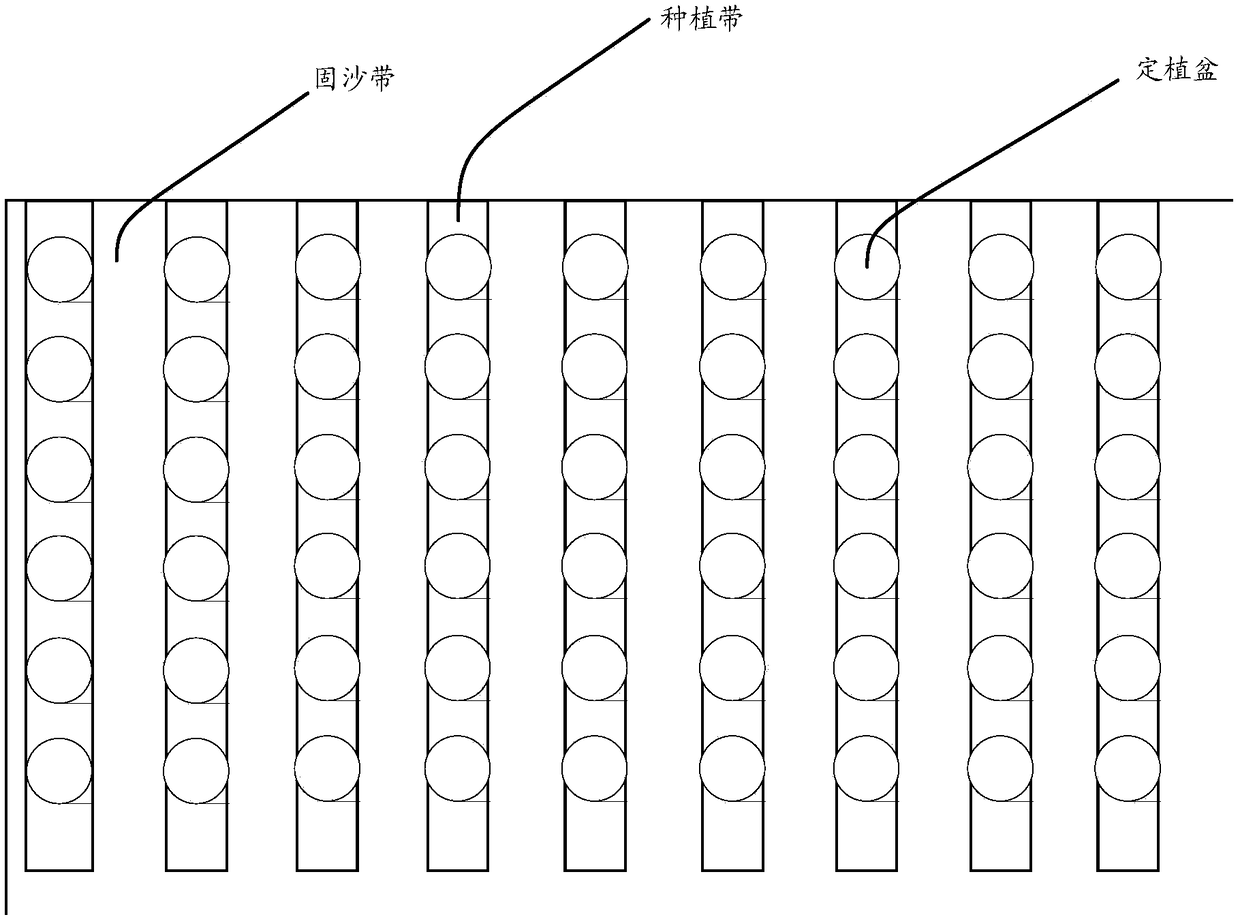

[0116] S33: Set planting belts and sand-fixing belts in parallel at intervals in the g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com