Extraction method of protein in sludge and application of protein

An extraction method and protein technology, which are applied to the preparation methods of peptides, chemical instruments and methods, and the dissolution of microorganisms, etc., can solve the problems of high protein impurity content, unsuitable for nitrogen-containing fertilizers, and low protein yield, etc., and achieve simple operation. , The effect of realizing resource utilization and reducing the difficulty of extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

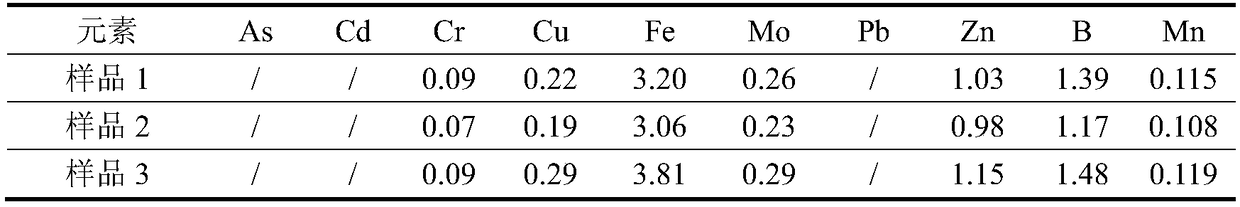

[0043] First, 80g of sludge with a moisture content of 93% was ultrasonically used for 40min with an energy of 180W. Then, 0.04g / gTSS of papain was added thereto, and the speed of the constant temperature oscillator was adjusted to 160r / min, and the temperature was 60°C. Put the sludge into a constant temperature oscillator for hydrolysis for 5 hours, and inactivate it in boiling water for 15 minutes after the hydrolysis is completed. Then, the sludge was centrifuged at 10,000 g for 20 min, and the precipitate was discarded to obtain 60 ml of supernatant, which was the crude protein extract. The protein concentration was 133.3 mg / gTSS as detected by the Lowry method.

[0044] Concentrate 50ml of the above protein supernatant, adopt ammonium sulfate precipitation method coupled with dialysis bag adsorption method, first put the solution on a magnetic stirrer and stir slowly, slowly add 15g of ammonium sulfate solid into 50ml of protein supernatant, After stirring for 6 hours, l...

Embodiment 2

[0046] First, 80 g of sludge with a moisture content of 93% is ultrasonically 30 min, and the energy is 150 W, then papain of 0.03 g / gTSS is added therein, the rotating speed of the constant temperature oscillator is adjusted to be 150 r / min, and the temperature is 55 ° C, and the papain that has been added is The sludge was hydrolyzed in a constant temperature oscillator for 4 hours, and inactivated in boiling water for 15 minutes after the hydrolysis was completed. Afterwards, the sludge was centrifuged under 8000g centrifugal force for 15 minutes, and the precipitate was discarded to obtain 56ml supernatant, which was the crude protein extract. The protein concentration was 108.4mg / gTSS detected by the Lowry method.

[0047] Concentrate 50ml of the above protein supernatant, adopt ammonium sulfate precipitation method coupled with dialysis bag adsorption method, first put the solution on a magnetic stirrer and stir slowly, slowly add 10g of ammonium sulfate solid into 50ml o...

Embodiment 3

[0049] First, 80 g of sludge with a water content of 93% is ultrasonically 50 min, and the energy is 200 W, and then papain of 0.05 g / gTSS is added therein, and the rotating speed of the constant temperature oscillator is adjusted to 170 r / min, and the temperature is 65 ° C. The sludge was hydrolyzed in a constant temperature oscillator for 6 hours, and inactivated in boiling water for 15 minutes after the hydrolysis was completed. Afterwards, the sludge was centrifuged under 11000g centrifugal force for 25min, and the precipitate was discarded to obtain 63ml supernatant, which was the crude protein extract. The protein concentration was 136.3mg / gTSS detected by the Lowry method.

[0050] Concentrate the above 50ml protein supernatant, adopt ammonium sulfate precipitation method coupled with dialysis bag adsorption method, first put the solution on a magnetic stirrer and stir slowly, slowly add 20g ammonium sulfate solid into 60ml protein supernatant, After stirring for 7 hour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com