Method for preparing organic-inorganic hybrid perovskite single crystal based on two-phase process

A perovskite and organic technology, applied in the field of perovskite solar cells, can solve the problems of unsustainable continuous growth of crystals, unfavorable stable and uniform growth of crystals, and inability to control crystal area, so as to ensure structural integrity and consistency. , low cost and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] 1. Prepare the lower halide solution

[0047] Clean the 100mL beaker and magnetic stirrer in advance, measure a total of 50mL of hydrobromic acid HBr and hypophosphorous acid H 3 PO 2 Pour into a beaker with a stirring bar, place the beaker on a hot stage, set the stirring temperature to 80°C, and stir for 1 hour. Then weigh 5.32g of synthesized MABr and 0.54g of CsBr into the beaker, seal the beaker with plastic wrap, continue heating and stirring for more than 30min, and obtain a Br compound solution with a concentration of 1.0mol / L.

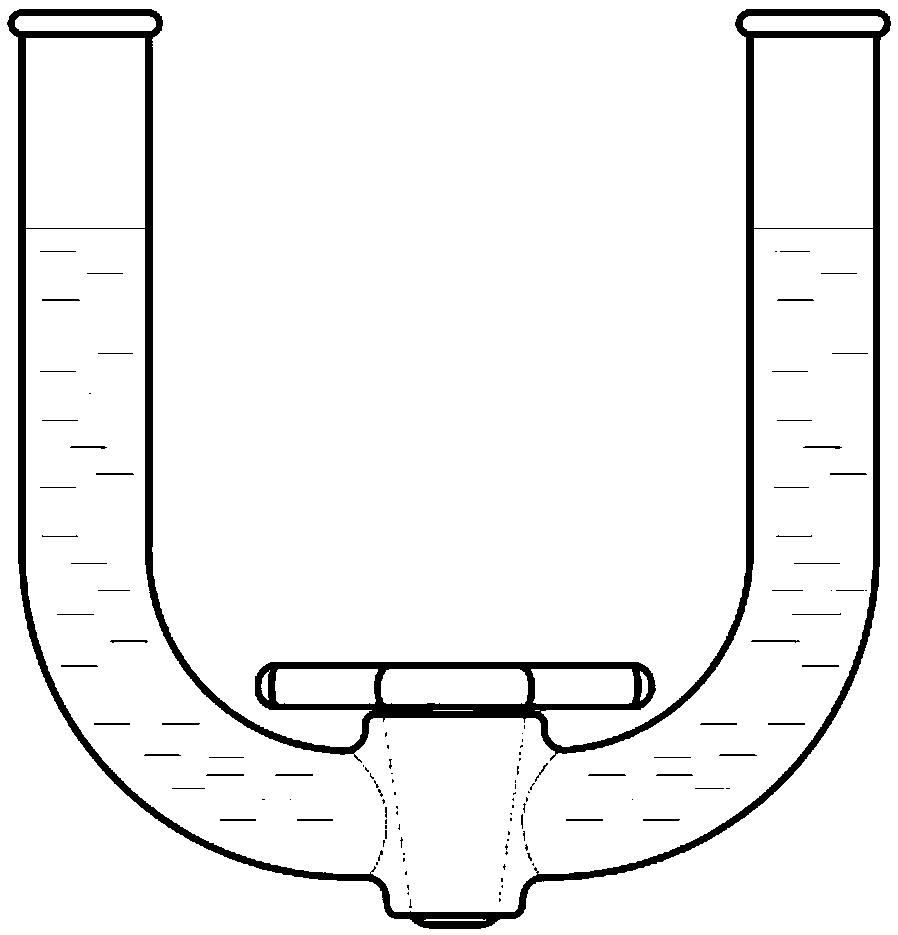

[0048] 2. Construction of two-phase interface

[0049] Fix the U-shaped tube with a valve in the oil bath of the heating platform, set the initial temperature to 80°C, slowly transfer the Br compound solution in the beaker to the U-shaped tube (open the valve), and wait until the liquid level is balanced and stable Finally, close the valve, slowly drop 25mL of organic substance cyclohexane with a density lighter than that of the lowe...

Embodiment 2

[0055] 1. Prepare the lower halide solution

[0056] Clean the 100mL beaker and magnetic stirrer in advance, measure a total of 30mL of HBr hydrobromide with a graduated cylinder, pour it into the beaker with a stirrer, place the beaker on a hot plate, set the stirring temperature to 70°C, and stir for 3 hours. Then weigh MABr into the beaker, seal the beaker with plastic wrap, and continue heating and stirring for more than 30 min to obtain a Br compound solution with a concentration of 5.0 mol / L.

[0057] 2. Construction of two-phase interface

[0058] Fix the U-shaped tube with a valve in the water bath of the heating platform, set the initial temperature to 70°C, slowly transfer the Br compound solution in the beaker to the U-shaped tube (open the valve), and wait until the liquid level is balanced and stable , close the valve, slowly drop 2mL of n-hexane, an organic compound with a density lighter than that of the lower solution, on one side of the U-shaped tube, to form...

Embodiment 3

[0064] 1. Prepare the lower halide solution

[0065] Clean the beaker and magnetic stirring bar in advance, and measure a total of 50mL of hydroiodic acid HI and hypophosphorous acid H with a graduated cylinder. 3 PO 2 Pour into a beaker with a stirring bar, place the beaker on a hot stage, set the stirring temperature to 70°C, and stir for 3 hours. Then weigh the synthesized FAI and add it to the beaker, seal the beaker with plastic wrap, continue heating and stirring for more than 30min, and obtain a compound I solution with a concentration of 0.1moL / L.

[0066] 2. Construction of two-phase interface

[0067] Fix the U-shaped tube with a valve in the oil bath of the heating platform, set the initial temperature to 70°C, slowly transfer the Br compound solution in the beaker to the U-shaped tube (open the valve), and wait until the liquid level is balanced and stable Finally, the valve was closed, and 5 mL of petroleum ether was slowly added dropwise with a dropper to one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com