A kind of preparation method of metal graphite composite bipolar plate of proton exchange membrane fuel cell

A technology of proton exchange membrane and metal bipolar plate, applied in the direction of fuel cells, fuel cell components, circuits, etc., can solve the problems of short service life, easy to fall off, high cost, etc., to reduce surface treatment costs and reduce manufacturing costs , Improve the effect of corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with drawings and embodiments.

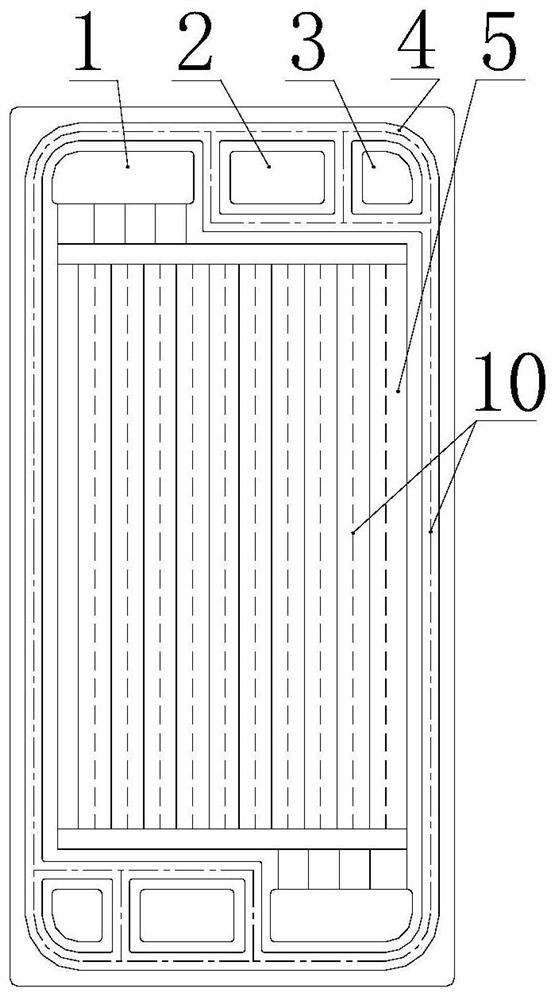

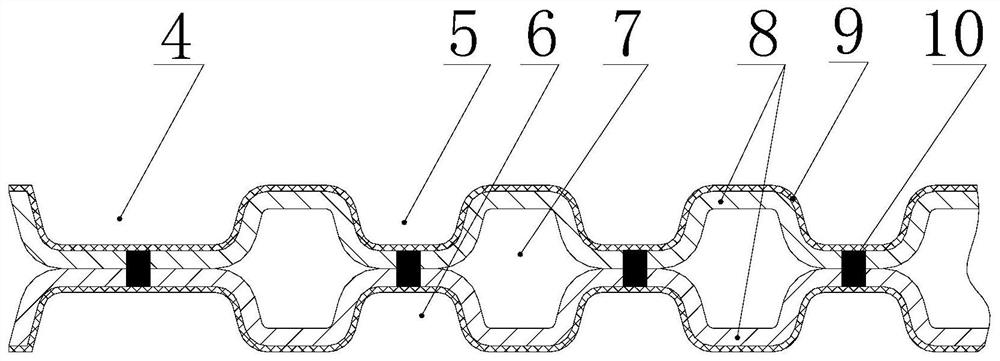

[0027] A method for preparing a metal-graphite composite bipolar plate for a proton exchange membrane fuel cell, comprising making the metal bipolar plate, treating flexible graphite paper and adhering the flexible graphite paper on the surface of the bipolar plate, and making the metal bipolar plate includes the following steps:

[0028] 1) Use 0.08mm-0.1mm 316L stainless steel sheet to mold the hydrogen unipolar plate and oxygen unipolar plate of the metal bipolar plate. The height and depth of the protrusions and grooves on the unipolar plate 8 are respectively 0.5mm-0.7mm scope;

[0029] 2) A hydrogen unipolar plate and an oxygen unipolar plate are welded together by fiber laser welding to form a bipolar plate. The thickness of the bipolar plate is in the range of 1 mm to 1.4 mm. The surface of the hydrogen unipolar plate has a hydrogen flow field 6 , the surface p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com