High strength scratch-resistant anti-cutting flexible protective film

A high-strength, protective film technology, applied in the coating and other directions, can solve the problems of being easily worn, scratched or cut, difficult to self-adhesive, and the flexibility of the woven material is reduced, so as to improve the flexibility and puncture resistance. , Avoid cracking or mildew, increase the effect of adsorption and antibacterial functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

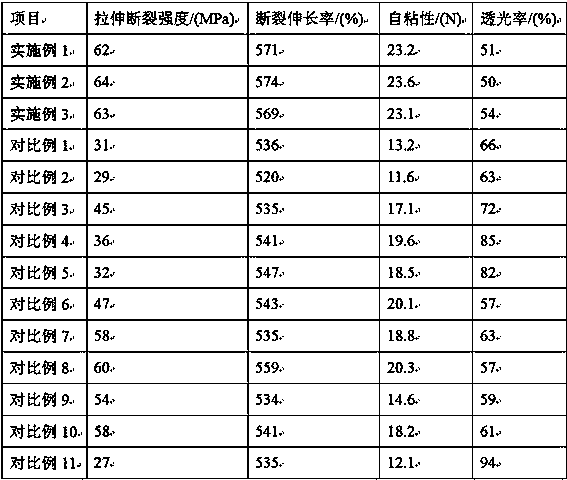

Embodiment 1

[0020] A high-strength anti-scratch and anti-cut flexible protective film is made of the following raw materials in parts by weight: modified polyvinyl chloride 67, linear low-density polyethylene 25, polyester fiber 22, sepiolite fiber 11, graphene fiber 8.

[0021] For the modified polyvinyl chloride, heat the polyvinyl chloride to 85°C at a rate of 1.2°C / min, keep it warm for 15 minutes, continue heating to 95°C, add zinc sulfate solution, the mass percentage concentration is 5%, add the weight It is 30% of the weight of polyvinyl chloride, heat preservation and stirring at 95°C until there is no moisture, naturally cool to 80°C, heat preservation and stirring for 2 hours, to obtain modified polyvinyl chloride; make polyvinyl chloride and zinc ions fully branched and polymerized, improve polyvinyl chloride The photothermal stability of vinyl chloride delays the aging process of polyvinyl chloride.

[0022] A method for preparing a high-strength scratch-resistant and cut-res...

Embodiment 2

[0028] A high-strength anti-scratch and anti-cut flexible protective film is made of the following raw materials in parts by weight: modified polyvinyl chloride 68, linear low-density polyethylene 26, polyester fiber 23, sepiolite fiber 12, graphene fiber 9.

[0029]For the modified polyvinyl chloride, heat the polyvinyl chloride to 88°C at a rate of 1.3°C / min, keep it warm for 18 minutes, continue heating to 97°C, add zinc sulfate solution, the mass percentage concentration is 6%, add the weight It is 35% of the weight of polyvinyl chloride, heat preservation and stirring at 97°C until there is no moisture, naturally cool to 83°C, heat preservation and stirring for 2 hours, and obtain modified polyvinyl chloride; make polyvinyl chloride and zinc ions fully branched and polymerized, and improve polyvinyl chloride. The photothermal stability of vinyl chloride delays the aging process of polyvinyl chloride.

[0030] A method for preparing a high-strength scratch-resistant and cu...

Embodiment 3

[0036] A high-strength anti-scratch and anti-cut flexible protective film is made of the following raw materials in parts by weight: modified polyvinyl chloride 69, linear low-density polyethylene 27, polyester fiber 24, sepiolite fiber 13, graphene fiber 10.

[0037] For the modified polyvinyl chloride, heat the polyvinyl chloride to 90°C at a rate of 1.4°C / min, keep it warm for 20 minutes, continue heating to 100°C, add zinc sulfate solution, the mass percentage concentration is 7%, add the weight It is 40% of the weight of polyvinyl chloride, heat preservation and stirring at 100°C until there is no moisture, naturally cool down to 85°C, heat preservation and stirring for 3 hours, and obtain modified polyvinyl chloride; make polyvinyl chloride and zinc ions fully branch and polymerize, and improve polyvinyl chloride. The photothermal stability of vinyl chloride delays the aging process of polyvinyl chloride.

[0038] A method for preparing a high-strength scratch-resistant ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com