Method for producing ruminant nutrition lick brick from arginine fermentation secondary product

A ruminant and production method technology, applied in the field of microbial fermentation technology and ruminant nutrition and breeding, can solve the problems of unbalanced overall development, no reports, no reports, etc., and achieves convenient licking, good palatability, The effect of increasing growth rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] The arginine fermentation broth is centrifuged and filtered with a ceramic membrane to resolve the arginine. After collection, all the remaining bacteria, liquid and intermediate resolved overflow liquid are called the secondary fermentation of arginine. Product, arginine fermentation secondary product enrichment process and conditions.

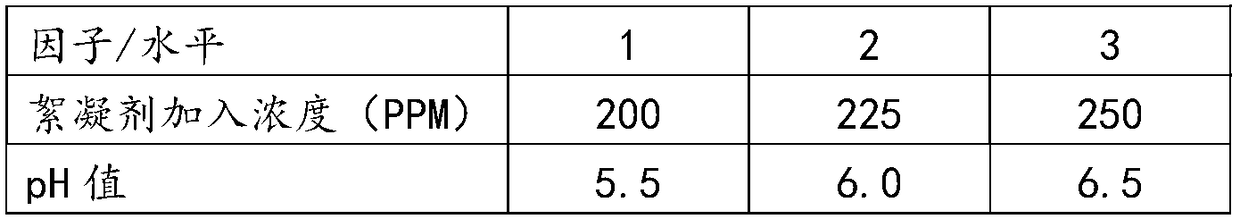

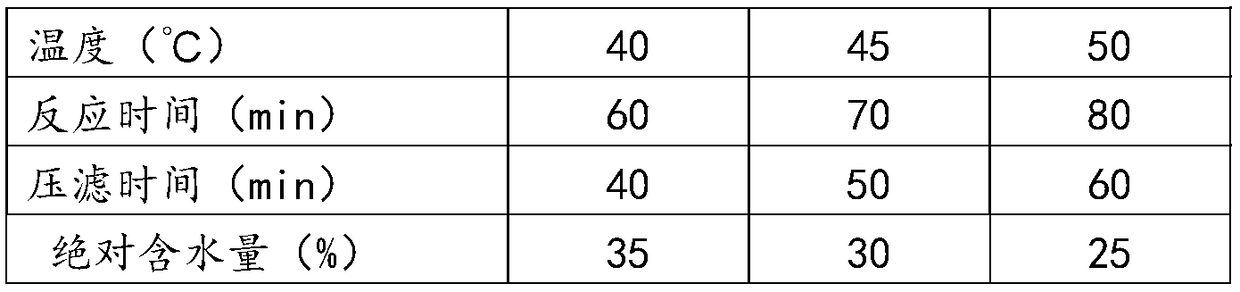

[0060] Put 18 tons of arginine fermentation secondary products into a 20-ton container and let it stand. Add the flocculant anionic polyacrylamide at 200-250ppm, adjust the pH value of the arginine fermentation broth to 5.5-6.5 with 10% dilute sulfuric acid by mass fraction, and react at a temperature of 40°C-50°C, and the reaction time is 60-80min. Then, press it into a filter press with a pressure of 3mpa, and press the filter for 40-60 minutes to obtain arginine fermentation secondary product wet powder with a water content of 25-30%.

[0061] Concentration Process and Condition Test of Secondary Product of Arginine Fermentation

...

Embodiment 2

[0068] Saccharomyces cerevisiae (protease, amino acid, vitamin, biotin) single colony purification, first-level solid seed culture, second-level liquid seed culture, inspection and determination of the number of bacteria, the specific operation steps are as follows:

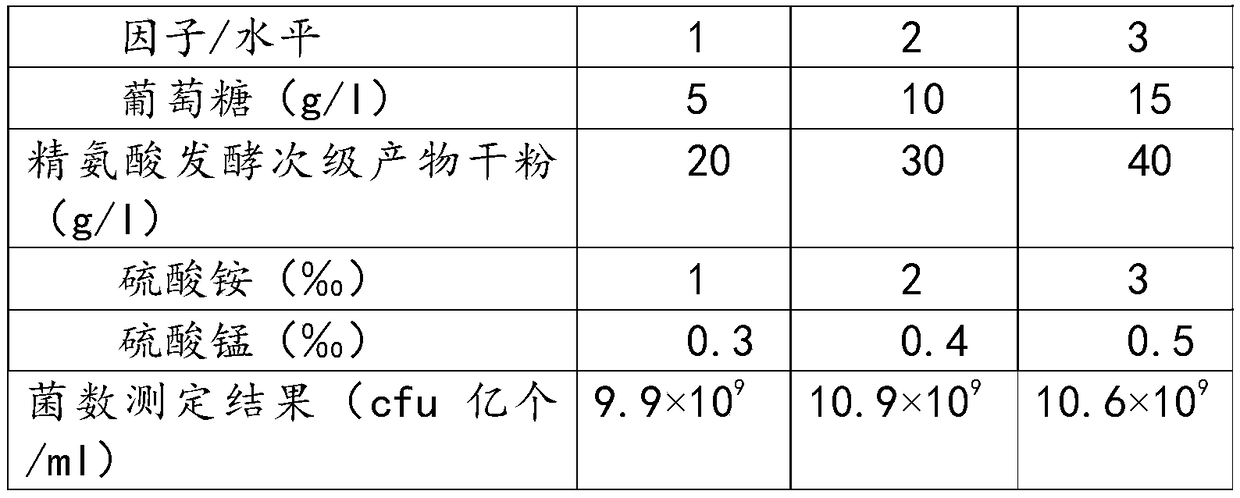

[0069] Secondary liquid fermentation culture (selection medium and culture condition test): Submerged fermentation method is adopted to produce fermentation liquid, and the first-grade solid seeds of the cultivated eggplant-shaped flat flask yeast are washed with 200mL sterile water into a 500mL sterile triangular flask In, inoculate in the fermentation tank with flame inoculation method or differential pressure, (fermentation tank can be 500 liters, 1 ton, 2 tons), liquid filling volume is no more than 70%, aerated fermentation culture. When the culture is mature, the bacterial liquid has a wine aroma, and the bacterial body is healthy under a microscope, and there is no abnormal phenomenon such as bacterial cont...

Embodiment 3

[0084] Bacillus subtilis (Bacillus subtilis), is a bacterial microorganism (mainly decomposes proteins to synthesize amino acids and peptides). The specific operation steps of single colony purification and optimization, solid primary seed cultivation, and liquid secondary fermentation cultivation are as follows:

[0085] Bacillus subtilis has the characteristics of fast conception speed, high temperature resistance, acid and alkali resistance, extrusion resistance, good stability and wide application range.

[0086] Secondary liquid fermentation culture: submerged fermentation is used to produce seed liquid, and the cultivated first-grade solid seeds of solanaceous flat flask are washed with 200mL sterile water into a 500mL sterile triangular flask, and flame inoculation method or pressure difference Inoculate in the fermenter, (the fermenter can be 500 liters, 1 ton, 2 tons), the filling capacity is no more than 70%. Check under the microscope that the bacteria are active, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com