Preparation method of microbial immobilized gel sphere, and application of microbial immobilized gel sphere in removal of norfloxacin and tetracycline in water

A technology of microbial immobilization and norfloxacin, applied in biological water/sewage treatment, immobilized on or in inorganic carriers, chemical instruments and methods, etc., can solve problems such as inability to remove, secondary pollution, etc., to avoid The effect of loss, efficient removal, and high microbial concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The preparation of microorganism-immobilized gel balls and the removal of norfloxacin and tetracycline in water include the following steps:

[0038] (1) Select cow feces to cultivate and domesticate microorganisms. The specific steps are to add feces into a sealed gas-producing culture device, and add wastewater containing norfloxacin or tetracycline to cultivate and acclimatize, change the water of the supernatant every day and add 1mg / L corresponding antibiotics to facilitate the production of energy The dominant strain resistant to the antibiotic. Regularly observe the gas production. When methane is produced, it means that the microorganisms resistant to the antibiotic have been screened out. Continue to cultivate until the system in the device is stable. When there are enough microorganisms, take out the microorganisms in the device for immobilization experiments. At this time, the microbial content in the device is 30%. .

[0039] (2) Dissolve SA in deionized w...

Embodiment 1

[0049] Embodiment 1: A kind of preparation method of microorganism immobilized gel ball

[0050] (1) 0.4g SA was dissolved in 20mL deionized water, stirred continuously and ultrasonically dispersed to obtain a homogeneous and transparent colloidal solution of SA with a mass volume fraction of 2%;

[0051] (2) 1g CaCl 2 Dissolved in 50mL deionized water to obtain CaCl with a mass volume fraction of 2% 2 homogeneous transparent solution;

[0052] (3) Add the solution of step (1) dropwise into the solution of step (2) in a water bath at 20°C with constant stirring through a peristaltic pump, and continue to stir for 1 hour. After the reaction is complete, stir and solidify at room temperature for 12 hours, and take out the gel Gumballs, washed with deionized water to remove excess Ca 2+ , that is, the microbe-immobilized gel ball 1: 0% microbe-0% CLDH-SA gel ball was obtained.

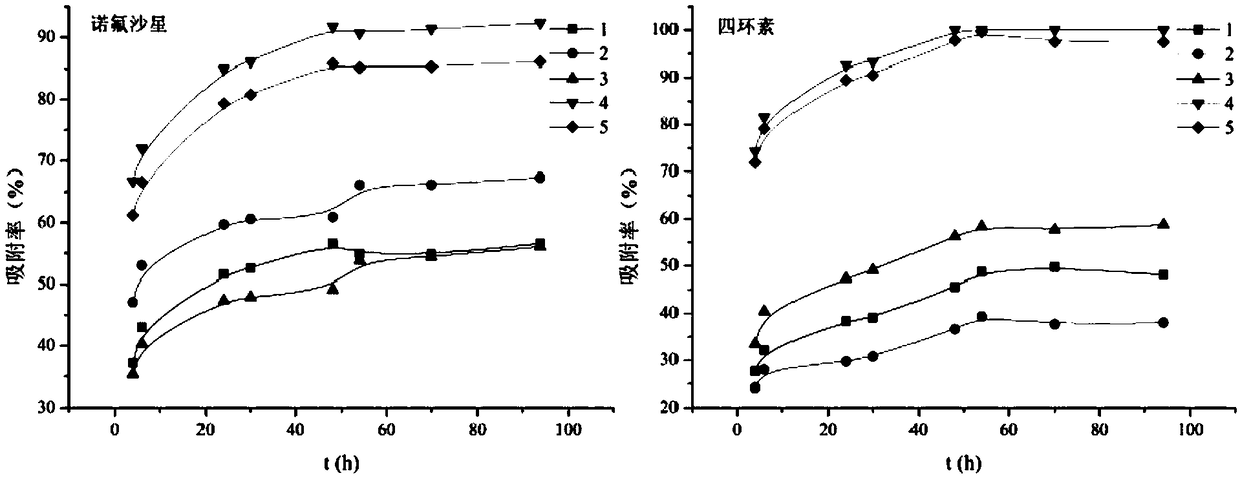

[0053] At room temperature, the removal rates of 20 microbe-immobilized gel spheres were 37.2%, 51...

Embodiment 2

[0054] Embodiment 2: A kind of preparation method of microorganism immobilized gel ball

[0055] (1) Select cow feces to cultivate and domesticate microorganisms. The specific steps are to take cow feces and add them to a sealed gas-producing culture device, and use simulated wastewater containing norfloxacin or tetracycline to cultivate and acclimatize. star or tetracycline) simulated wastewater concentration of 1mg / L. Regularly observe the gas production every morning and evening. After 7 days of cultivation and acclimation, about 10-20mL of methane gas was collected at the gas collection port, indicating that the microorganisms that can resist the antibiotic have been screened out. Continue to cultivate and acclimatize the microorganisms and monitor the pH value and gas production every day. and antibiotic concentrations. After about 30 days of domestication and cultivation, the pH value is stable at about 7.5, the gas production rate is 110-130mL / d, and the removal rate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com