Preparation method of catalytic electrode for electrochemical synthesis of borohydride

A borohydride, catalytic electrode technology, applied in electrodes, electrolysis components, electrolysis processes, etc., can solve the problems of difficult separation and purification of products, industrialized production, lack of practical value, etc., to achieve optimized stability and reversible performance, Effects of multiple catalytically active sites, excellent electrical conductivity and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] A method for preparing a catalytic electrode for electrochemically synthesizing borohydride mainly comprises the following steps:

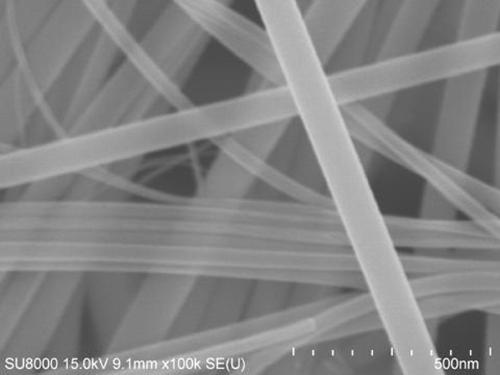

[0035] (1) Hydrothermal growth of titanium oxide micro-nano wires on the titanium substrate: select a piece of metal titanium sheet with an appropriate area and thickness, immerse it in the degreasing agent, treat it with ultrasonic waves for 20~40min, and then put it into the etching solution for 40~ Ultrasonic treatment at 60°C for 25-35min, take out the titanium sheet, wash it with distilled water, immerse it in the hydrothermal solution in an upright manner, and conduct a hydrothermal treatment at 200-250°C for 8-12h; after the hydrothermal treatment, take out the titanium sheet and wash it with water clean, and then vacuum dry at 40~60℃ for 5~8h to get TiO 2 -NWs / Ti, placed in a vacuum desiccator for standby;

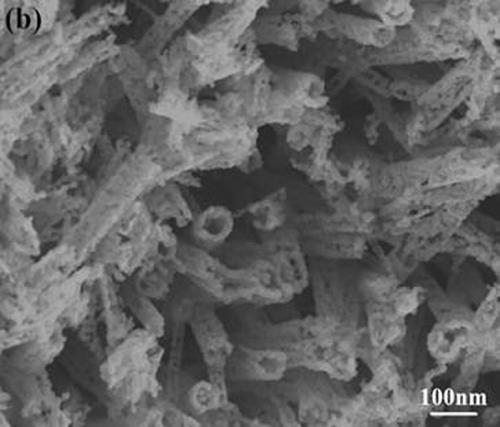

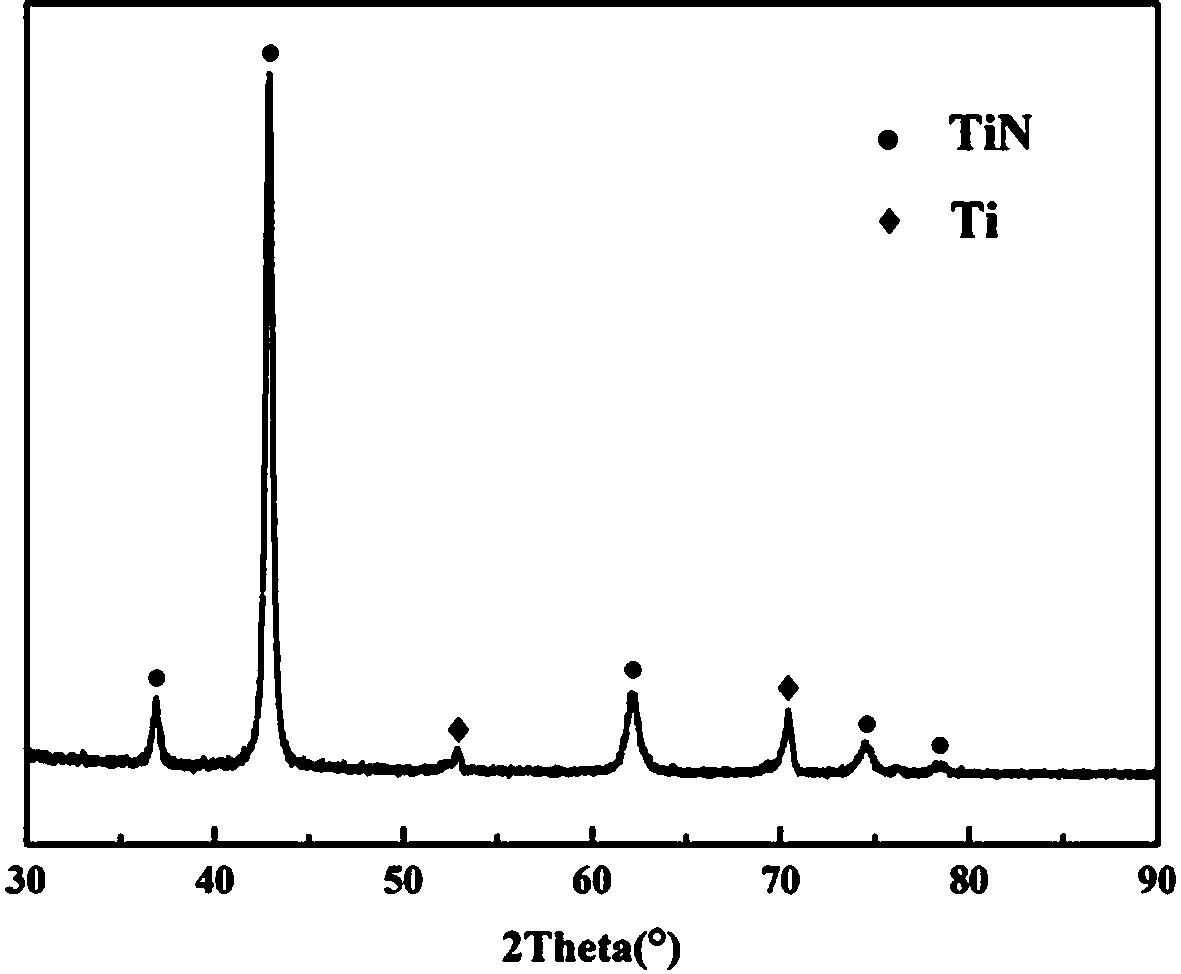

[0036] (2) Ammonia nitrogen reduction of titanium oxide micro-nanowires on titanium sheet: the TiO obtained in step (1) 2 -N...

Embodiment 1

[0045] A method for preparing a catalytic electrode for electrochemically synthesizing borohydride, comprising the following steps:

[0046] Step 1: Take a 1.0 cm×1.5cm×0.3mm metal titanium sheet, immerse it in 20ml of a mixed solvent composed of acetone and absolute ethanol (the volume ratio of the two is 2:1), and ultrasonically treat it for 30 minutes; take it out and put it in In 20ml of etching solution formed by ammonium fluoride, hydrogen peroxide, nitric acid and urea (molar ratio 1:1:1:0.05), ultrasonically treat at 50°C for 30min; take out the titanium sheet, wash it with distilled water, and set it upright immersion in 1.0 mol∙l -1 In the hydrothermal solution of tetramethylammonium hydroxide, hydrothermal treatment was carried out at 200°C for 8h; after hydrothermal treatment, the titanium sheet was taken out, cleaned with water, and then vacuum-dried at 40°C for 5h to obtain TiO 2 -NWs / Ti, placed in a vacuum desiccator for standby;

[0047] Step 2: TiO obtained ...

Embodiment 2

[0051] Step 1: Take a 1.0 cm×2.0cm×0.5mm metal titanium sheet, immerse it in 20ml of a mixed solvent composed of acetone and absolute ethanol (the volume ratio of the two is 2:1), and ultrasonically treat it for 20 minutes; take it out and put it in In 20ml of etching solution formed by ammonium fluoride, hydrogen peroxide, nitric acid and urea (molar ratio 1:1:1:0.05), ultrasonically treat at 60°C for 25min; take out the titanium sheet, wash it with distilled water, and set it upright way to immerse in 2.0 mol∙l -1 In the hydrothermal solution of tetramethylammonium hydroxide, hydrothermal treatment was carried out at 250°C for 12h; after hydrothermal treatment, the titanium sheet was taken out, cleaned with water, and then vacuum-dried at 60°C for 8h to obtain TiO 2 -NWs / Ti, placed in a vacuum desiccator for standby;

[0052] Step 2: TiO obtained in Step 1 2 -NWs / Ti is placed in a tube-type atmosphere furnace at a rate of 150ml∙min -1 Nitrogen gas was fed at the same flow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com