Hydrated glass-based sodium-ion battery quasi-solid electrolyte and preparation method and application

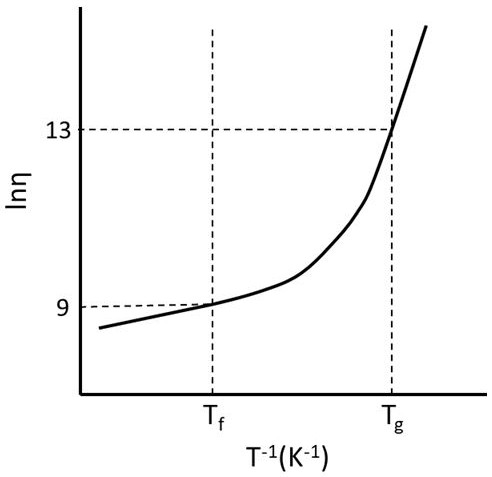

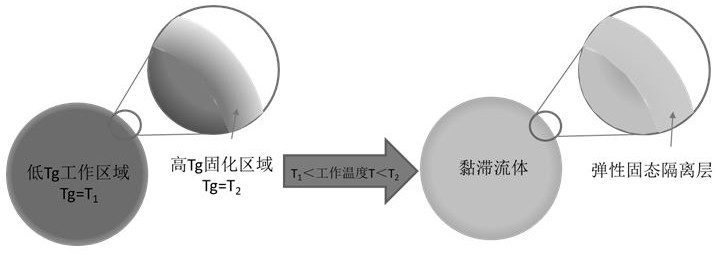

A sodium-ion battery, electrolyte technology, applied in electrolytes, secondary batteries, circuits and other directions, can solve the problems of poor gel cycle performance, poor cycle performance, unfavorable network structure, etc., to ensure stability and safety performance, good Effects of ion transport properties, high ionic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The preparation method of the sodium ion battery electrolyte of described hydrated glass base, the steps are as follows:

[0036] 1) Press Na 2 O:B 2 o 3 :SiO2 2 :H 2 O = 8-30:0.5-3:20-70:2-60 Weigh the required matrix raw materials, add 0-10 wt% sodium salt external admixture, mix and stir in the reaction kettle at room temperature Uniform, after standing for clarification and aging, a colorless transparent liquid is formed;

[0037] 2) Heat the above colorless transparent liquid at 20-350 °C for 12-48 h to control the water content, and obtain a viscous liquid electrolyte with a water content greater than 20 wt% or an elastic solid with a water content less than 20 wt% at room temperature electrolyte;

[0038] 3) Depending on the state at room temperature, the viscous liquid electrolyte is assembled and formed by the pouring-heat sealing method, and the elastic solid electrolyte is assembled and formed by the curing hot pressing method. During the assembly and m...

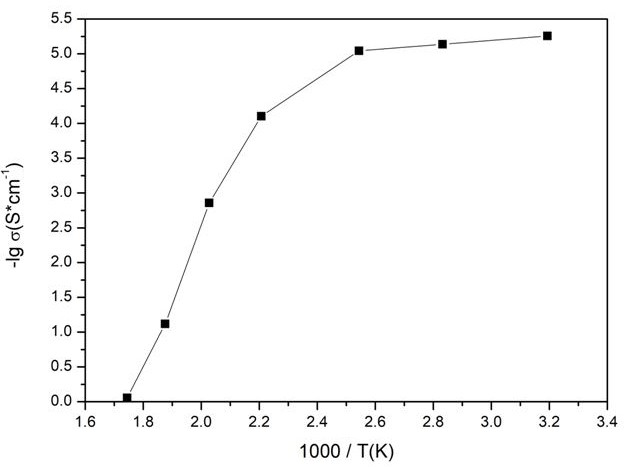

Embodiment 1

[0052] Press Na 2 O:B 2 o 3 :SiO2 2 :H 2 O = 20:2:60:18 mass ratio. The raw materials used are sodium silicate aqueous solution and boric acid, and the test battery is assembled by the above curing hot pressing method. The drying temperature is 20°C, and the hot pressing temperature is 70°C. The electrochemical performance test was carried out on the assembled battery, and the working temperature was 60 ℃ during the test.

Embodiment 2

[0054] Press Na 2 O:B 2 o 3 :SiO2 2 :H 2 O = 19.6:2:58.8:17.4 matrix mass ratio, sodium salt 2 wt%. The raw materials used are sodium silicate aqueous solution, boric acid, and sodium sulfate, and the test battery is assembled by the above curing hot pressing method. The drying temperature is 20°C, and the hot pressing temperature is 70°C. The electrochemical performance test was carried out on the assembled battery, and the working temperature was 60 ℃ during the test.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com