Cultivation method for camellia oleifera bud stock

A cultivation method and technology of camellia oleifera, which are applied in the field of plant propagation, can solve problems such as the germination rate and emergence rate of bud anvils need to be further improved, the sand bed has poor moisture retention, and the survival rate is not high, so as to achieve environmental protection in the cultivation process, significant germination effect, Improve the effect of nutrition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

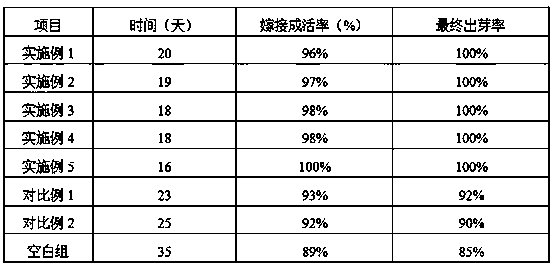

Examples

Embodiment 1

[0029] A method for cultivating Camellia oleifera bud stocks, comprising the steps of:

[0030] ⅠCamellia oleifera seed screening: The fresh fruits of camellia oleifera that have been sun-dried artificially, the moldy and rotten seeds are manually removed, and then graded, and the camellia oil seeds with full grains are screened with 50 mesh iron;

[0031] II Seed soaking: Put the Camellia oleifera seeds screened out in step I into clear water and soak for 1 hour, remove the floating seeds, then put them into the germination-promoting solution and soak the seeds for 2 hours at a temperature of 30°C, take them out, and let the surface dry;

[0032] ⅢModification of sawdust: Pull back 800g of sawdust from the band saw factory and use a 50-mesh iron sieve to remove impurities, add it to a three-necked bottle filled with 2500g of ethanol, and add 3-(2,3-epoxy Propoxy) propyltrimethoxysilane 50g, stirred and reacted at room temperature for 1 hour, then continued to add chitosan 100...

Embodiment 2

[0038] A method for cultivating Camellia oleifera bud stocks, comprising the steps of:

[0039] ⅠCamellia oleifera seed screening: The fresh fruits of camellia oleifera that have been sun-dried artificially, the moldy and rotten seeds are manually removed, and then graded, and the camellia oil seeds with full grains are screened with 70 mesh iron;

[0040] II Seed soaking: put the Camellia oleifera seeds screened out in step I into clear water and soak for 1.2 hours first, remove the floating seeds, then put them into the germination-promoting solution and soak the seeds for 2.3 hours at a temperature of 32°C, take them out, and let the surface dry;

[0041] ⅢModification of sawdust: Pull back 850g of sawdust from the band saw factory and use a 65-mesh iron sieve to remove impurities, add it to a three-necked bottle filled with 2600g of ethanol, and add 3-(2,3-epoxy Propoxy) propyltrimethoxysilane 50g, stirred and reacted at room temperature for 1.2 hours, then continued to add ...

Embodiment 3

[0047] A method for cultivating Camellia oleifera bud stocks, comprising the steps of:

[0048] ⅠCamellia oleifera seed screening: The fresh fruits of camellia oleifera that have been sun-dried artificially, the moldy and rotten seeds are manually removed, and then graded, and the camellia oil seeds with full grains are screened with 75 mesh iron;

[0049] II Seed soaking: Put the Camellia oleifera seeds screened out in step I into clear water and soak for 1.5 hours first, remove the floating seeds, then put them into the germination-promoting solution and soak the seeds for 2.5 hours at a temperature of 32°C, take them out, and let the surface dry;

[0050] ⅢModification of sawdust: Pull back 900g of sawdust from the band saw factory and use a 75-mesh iron sieve to remove impurities, add it to a three-necked bottle filled with 2800g of ethanol, and add 3-(2,3-epoxy Propoxy) propyltrimethoxysilane 50g, stirred and reacted at room temperature for 1.5 hours, then continued to ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com