Ferrous glycine enteric-soluble sustained-release pellets with coated structures, and preparation method of ferrous glycine enteric-soluble sustained-release pellets

A technology of ferrous glycinate and ferrous glycinate, which is applied in the field of feed preparation, can solve the problems of reducing the absorption of ferrous glycinate, being oxidized and deteriorating, and the properties of ferrous iron are unstable, so as to avoid the interference of oxygen and water and overcome the properties of ferrous glycine. Unstable, bioavailability-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

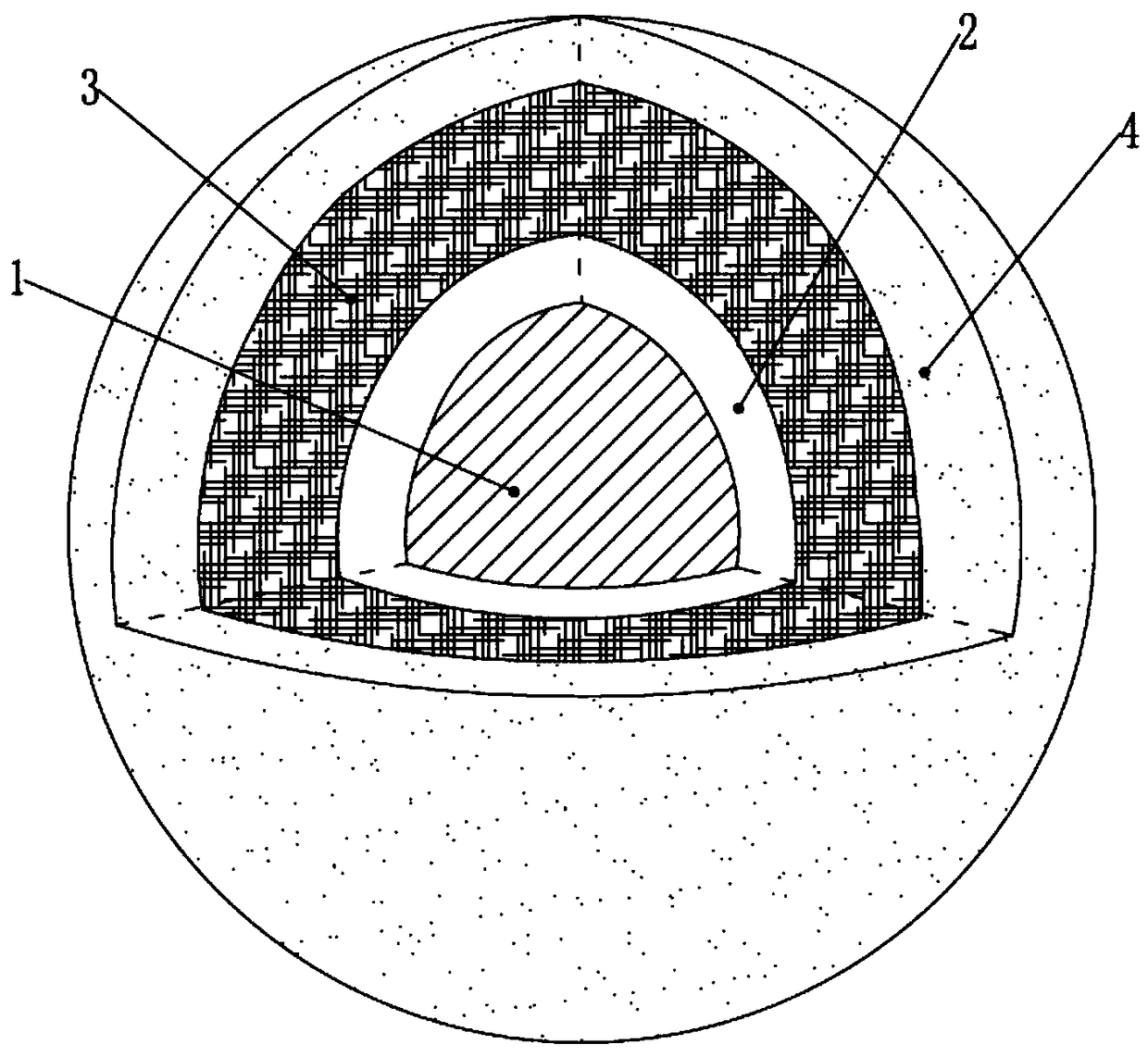

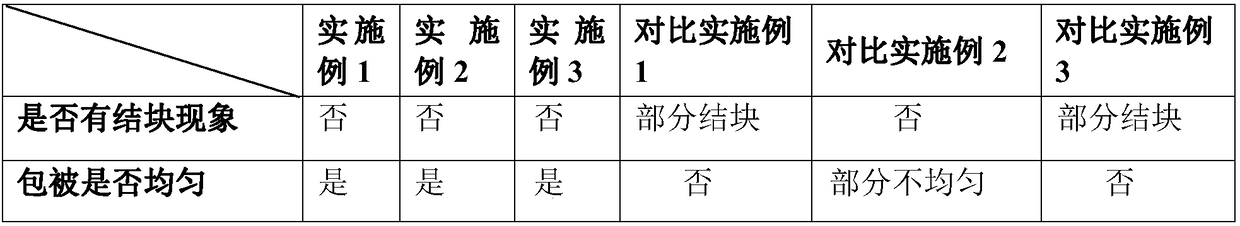

[0035] Embodiment 1-a preparation method of ferrous glycinate enteric-coated sustained-release pellets with a coating structure, comprising the following steps:

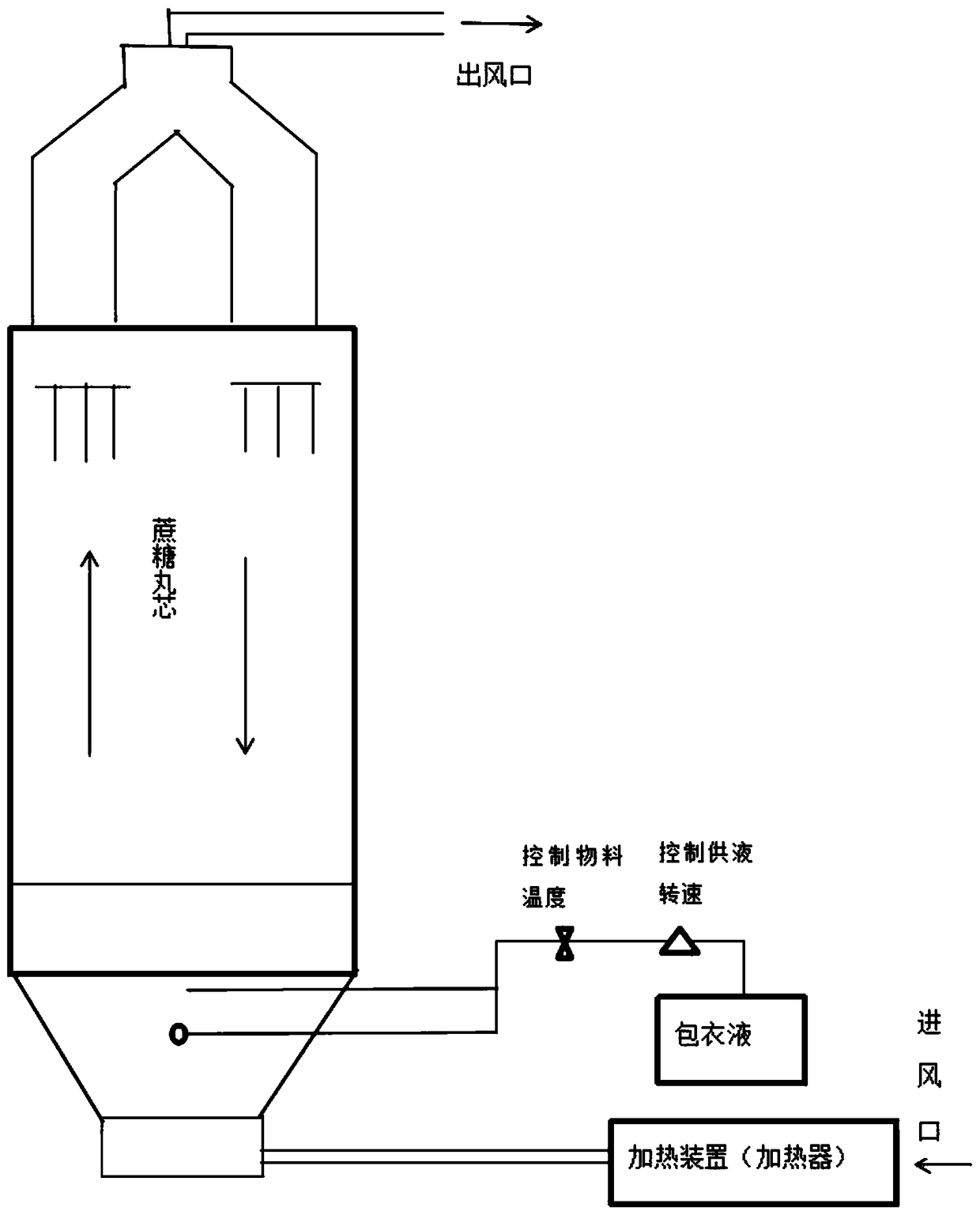

[0036] (1) After preheating the coating device, put the sucrose ball core into the coating device, and start the exhaust and dust collection device;

[0037] (2) Preheating the sucrose core with hot air, so that the sucrose core is evenly heated, and absorbs the fine powder adsorbed on the sucrose core;

[0038] (3) Open the compression pump, and adjust the fan frequency to be 18 and the liquid supply speed to be 12, spray the prepared drug-loaded coating solution, isolation coating solution, and enteric coating solution to the surface of the sucrose pellet core successively, and The coating liquid temperature of each layer is 45 ℃;

[0039] Wherein, the formulation components of the drug-loaded coating solution include a hydroxypropylmethylcellulose solution with a concentration of 0.035g / ml and a ferrous glycinate...

Embodiment 2

[0041] Embodiment 2-a preparation method of ferrous glycinate enteric-coated sustained-release pellets with a coating structure, comprising the following steps:

[0042] (1) After preheating the coating device, put the sucrose ball core into the coating device, and start the exhaust and dust collection device;

[0043] (2) Preheating the sucrose core with hot air, so that the sucrose core is evenly heated, and absorbs the fine powder adsorbed on the sucrose core;

[0044] (3) Open the compression pump, and adjust the fan frequency to be 17 and the liquid supply speed to be 8, spray the prepared drug-loaded coating solution, isolation coating solution, and enteric coating solution to the surface of the sucrose ball core successively, and The coating liquid temperature of each layer is 42 ℃;

[0045] Wherein the formulation components of the drug-loaded coating solution include a hydroxypropylmethylcellulose solution with a concentration of 0.035g / ml and a ferrous glycinate sol...

Embodiment 3

[0048] Embodiment 3-a preparation method of ferrous glycinate enteric-coated sustained-release pellets with a coating structure, comprising the following steps:

[0049] (1) After preheating the coating device, put the sucrose ball core into the coating device, and start the exhaust and dust collection device;

[0050] (2) Preheating the sucrose core with hot air, so that the sucrose core is evenly heated, and absorbs the fine powder adsorbed on the sucrose core;

[0051] (3) Open the compression pump, and adjust the fan frequency to be 17 and the liquid supply speed to be 10, spray the prepared drug-loaded coating solution, isolation coating solution, and enteric coating solution to the surface of the sucrose ball core successively, and The coating liquid temperature of each layer is 44 ℃;

[0052] Wherein, the formulation components of the drug-loaded coating solution include a hydroxypropylmethylcellulose solution with a concentration of 0.035g / ml and a ferrous glycinate s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com