Catalyst for removing oxygen from hydrogen, preparation method and applications thereof

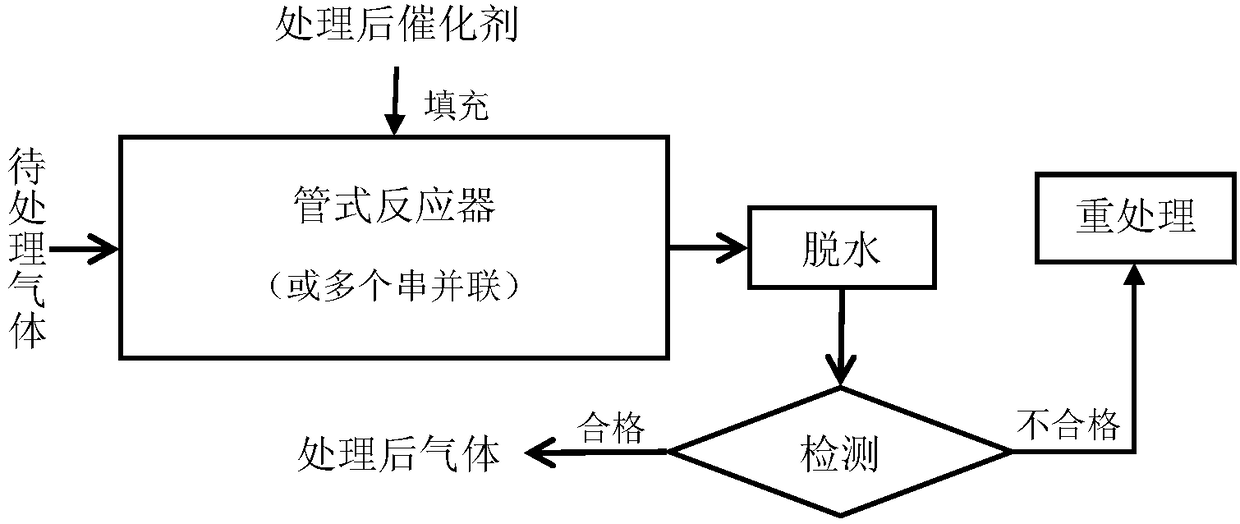

A catalyst and hydrogen technology, applied in the direction of catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, catalyst carrier, etc., can solve the problem that the hydrogen content should not exceed 2%, and the hydrogen content of hydrogen production equipment should not be low 99.5%, the oxygen content does not exceed 0.5%, the danger of oxygen, the high temperature of deoxidation operation, etc., to achieve high dispersion and uniformity, enhance the service life, and the effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

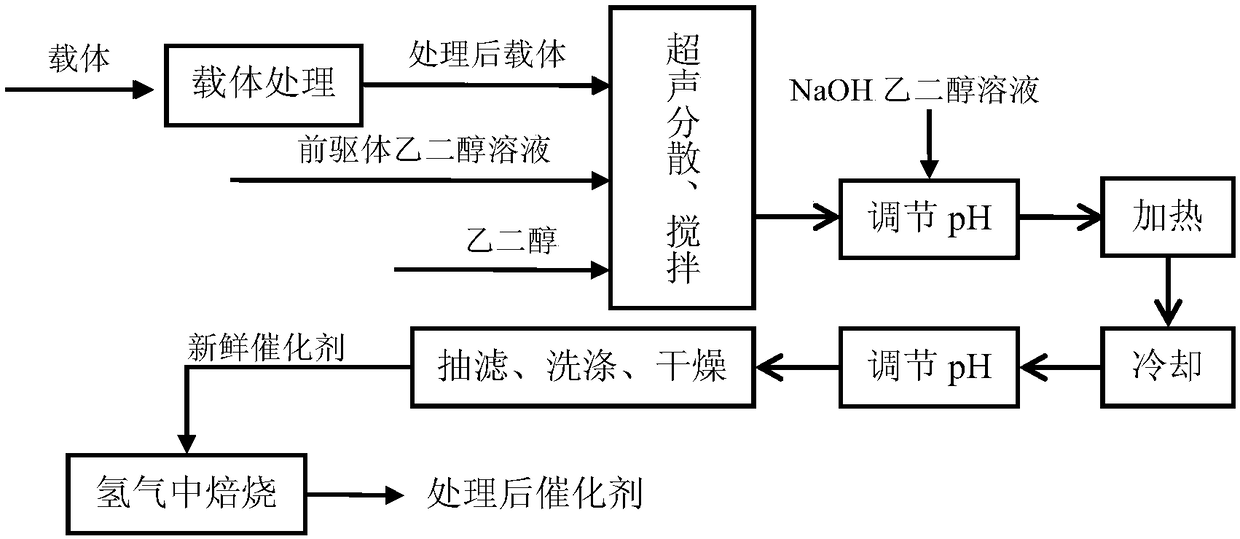

Method used

Image

Examples

Embodiment 1

[0046] A catalyst for removing oxygen from hydrogen, comprising a metal precursor and a support, whose general chemical formula is PtRuFe / TiO 2 , wherein the metal precursors, by weight percentage, are loaded with Pt 0.6%, Ru 0.3%, Fe 0.2%; the mass percentage of titanium dioxide is 98.9%.

[0047] Further, the catalyst is gray powder with a specific surface area of 100m 2 / g.

[0048] The preparation method of above-mentioned catalyst, comprises the following steps:

[0049] (1) configuration contains Pt, Ru, the ethylene glycol solution I of the soluble salt of Fe;

[0050](2) configure the ethylene glycol solution II of sodium hydroxide with a molar concentration of 1mol / mL;

[0051] (3) The carrier titanium dioxide does not need to be pre-treated. It is directly weighed into a three-neck round bottom flask, added with ethylene glycol, and fully ultrasonically dispersed to form a suspension;

[0052] (4) measure ethylene glycol solution 1, place ultrasonic dispersion ...

Embodiment 2

[0063] A catalyst for removing oxygen from hydrogen, comprising a metal precursor and a carrier; its general chemical formula is Pt / TiO 2 , the metal precursor is Pt, and the amount of Pt is 1% by weight percentage; the mass percentage of titanium dioxide is 99%.

[0064] Further, the catalyst is gray powder with a specific surface area of 50m 2 / g.

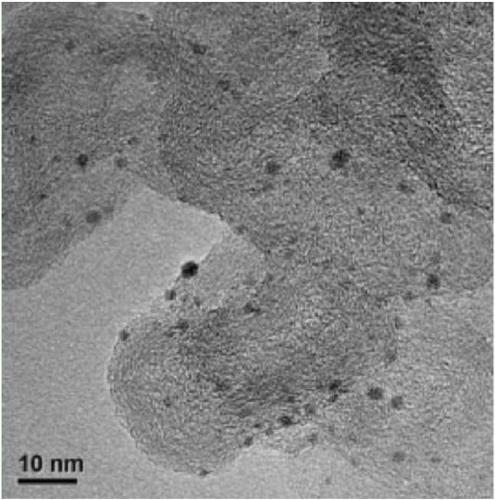

[0065] Further, the particle diameter of Pt is 3.2 nm.

[0066] The preparation method of above-mentioned catalyst, comprises the following steps:

[0067] (1) configuration contains the ethylene glycol solution I of the soluble salt of Pt;

[0068] (2) configure the ethylene glycol solution II of sodium hydroxide with a molar concentration of 1mol / mL;

[0069] (3) The carrier titanium dioxide does not need to be pre-treated. It is directly weighed into a three-neck round bottom flask, added with ethylene glycol, and fully ultrasonically dispersed to form a suspension;

[0070] (4) measure ethylene glycol solution 1, place...

Embodiment 3

[0079] A catalyst for removing oxygen from hydrogen, comprising a metal precursor and a carrier; its general chemical formula is Pt / Al 2 o 3 , the metal precursor is Pt, and the amount of Pt is 5% by weight percentage; the mass percentage of aluminum oxide is 95%.

[0080] Further, the catalyst is gray powder with a specific surface area of 200m 2 / g.

[0081] Further, the particle size of Pt is 1.6 nm.

[0082] The preparation method of above-mentioned catalyst, comprises the following steps:

[0083] (1) configuration contains the ethylene glycol solution I of the soluble salt of Pt;

[0084] (2) configure the ethylene glycol solution II of sodium hydroxide with a molar concentration of 1mol / mL;

[0085] (3) The carrier aluminum oxide is crushed and ground to less than 300 mesh before use, and roasted in the air at 500°C for 2 hours, stored in a desiccator for later use, weighed into a three-neck round bottom flask before use, and added ethylene glycol, Fully ultraso...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com