Preparation method of filter cleaner rubber slice

A filter and film technology, which is applied in the field of filter film preparation, can solve the problems of short service life, waste, and limited use of filters, and achieve good low-temperature impact resistance, improved service life, and good dimensional stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

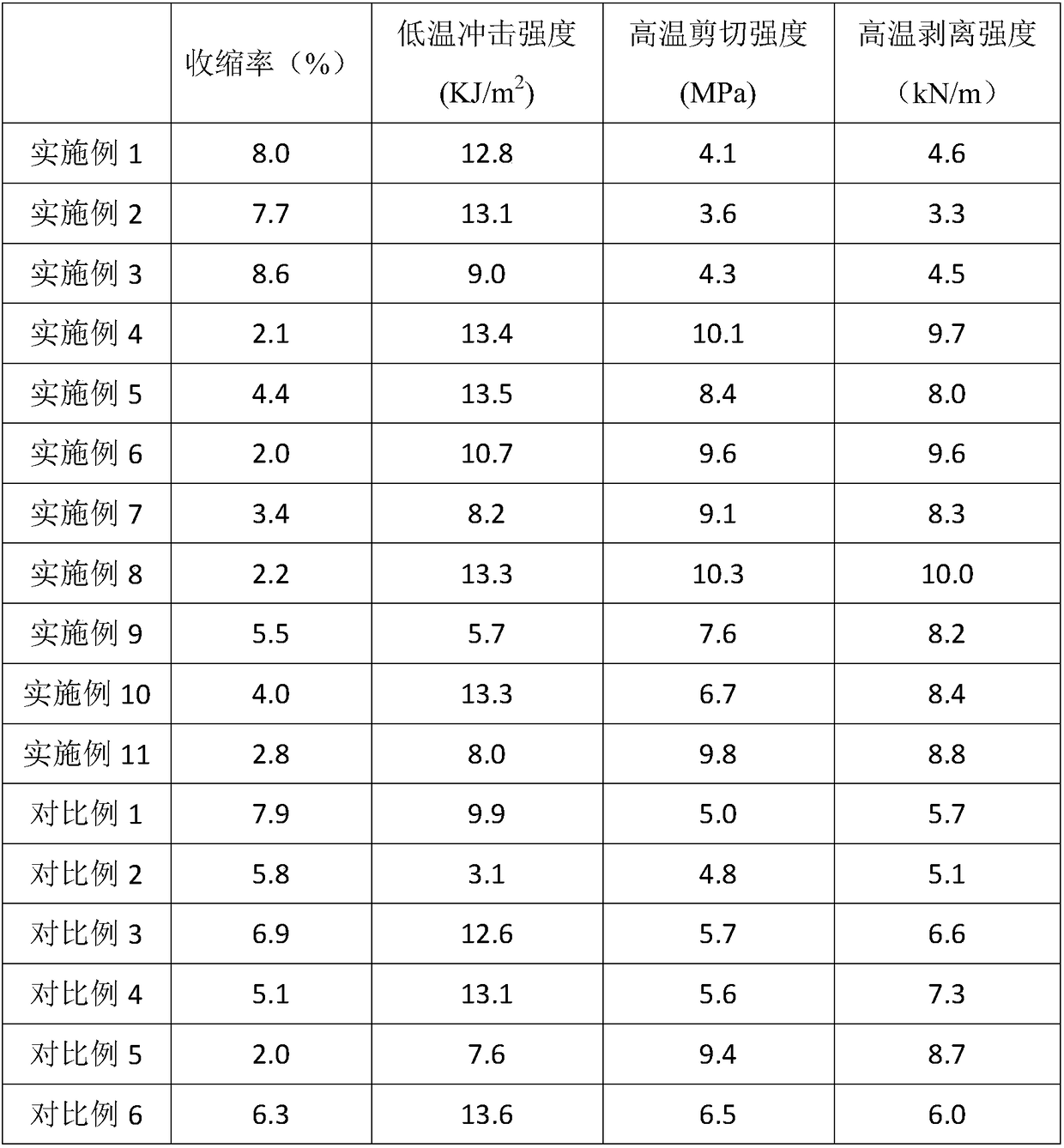

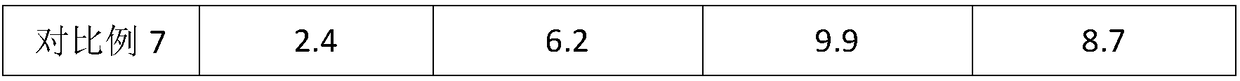

Examples

preparation example Construction

[0018] In order to solve the above technical problems, the first aspect of the present invention provides a method for preparing filter film, which at least includes the following steps:

[0019] Put the nitrile rubber and phenolic resin into the mixer, control the temperature at 60~100℃, mix for 1~5min, add additives to it, continue mixing for 1~5min, add vulcanizing agent, The curing agent and curing accelerator are mixed in two stages for 1 to 5 minutes; the mixed rubber is placed at room temperature for 6 to 24 hours, and then vulcanized at 220 to 270°C for 1 to 3 minutes to obtain the filter film.

[0020] Nitrile rubber is produced by emulsion polymerization of butadiene and acrylonitrile. Nitrile rubber is mainly produced by low-temperature emulsion polymerization. It has excellent oil resistance, high wear resistance and strong adhesion. But long-term performance in sour gasoline and high temperature environment is not good, and the dimensional stability at high temperatur...

Embodiment 1

[0051] Embodiment 1 provides a method for preparing filter film, including the following steps:

[0052] Put 35g nitrile rubber and 77g phenolic resin into the mixer, control the temperature at 80℃, mix for 1min, add 0.6g antioxidant ODA (4,4'-dioctyldiphenylamine), 0.4g stearic acid , 0.4g zinc stearate, continue mixing for 2 minutes and then discharge the rubber. After the rubber is cooled, perform two-stage mixing. During the second-stage mixing, add 0.3g sulfur, 0.5g 2-mercaptobenzothiazole, 0.4g Dibenzothiazole disulfide and 5g of hexamethylenetetramine curing agent mixed with dicumyl peroxide are mixed in two stages for 5 minutes; the mixed compound is placed at room temperature for 12 hours, and then at 250°C After vulcanizing for 1 min, the filter film is obtained by debinding, forming and cutting.

[0053] The nitrile rubber is NBR 1704 brand rubber with an acrylonitrile content of 17-20%, purchased from Lanzhou Chemical Industry Company; the phenolic resin is a linear bi...

Embodiment 2

[0055] Embodiment 2 provides a method for preparing filter film, including the following steps:

[0056] Put 35g nitrile rubber and 52g phenolic resin into the mixer, control the temperature at 60℃, mix for 1min, add 0.6g antioxidant ODA (4,4'-dioctyldiphenylamine), 0.4g stearic acid , 0.4g zinc stearate, continue mixing for 1 minute and then discharge the rubber. After the rubber is cooled, perform two-stage mixing. During the second-stage mixing, add 0.3g sulfur, 0.5g 2-mercaptobenzothiazole, 0.4g Dibenzothiazole disulfide, 5g of hexamethylenetetramine curing agent mixed with dicumyl peroxide for two-stage mixing, mixing for 1 minute; the mixed compound is placed at room temperature for 6 hours, and then at 220 ℃ After vulcanizing for 3 minutes, the filter film is obtained by debinding, forming, and cutting.

[0057] The nitrile rubber is NBR 1704 brand rubber with an acrylonitrile content of 17-20%, purchased from Lanzhou Chemical Industry Company; the phenolic resin is a linea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com