Anticorrosive coating

A technology for anti-corrosion coatings and pigments, applied in the field of coatings, can solve the problems of poor anti-corrosion effect, prevent metal corrosion, poor high temperature tolerance, etc., and achieve the effects of reducing moisture absorption, improving corrosion resistance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

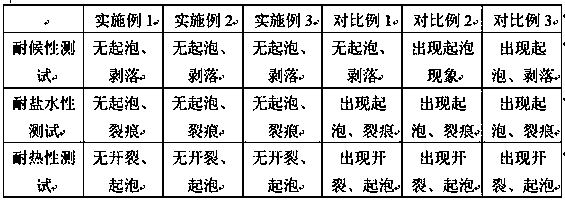

Examples

Embodiment 1

[0019] 50 parts of 4-vinyl epoxycyclohexane, 0.5 parts of dialkoxy coupling agent, 1 part of methyl silicone resin, 1 part of silicone, 1 part of carboxylate, 2 parts of talc, 8 parts of iron red powder , 21 parts of high-boiling aromatic hydrocarbon solvents.

Embodiment 2

[0021] 95 parts of 3,4-epoxycyclohexyl methyl methacrylate, 8 parts of dialkoxy coupling agent, 7 parts of silicone polyester resin, 2 parts of silicone, 2 parts of sulfate ester salt, 10 parts of kaolin, 15 parts of iron red powder, 50 parts of xylene and high boiling point aromatic hydrocarbon solvent.

Embodiment 3

[0023] 75 parts of dicyclopentadiene epoxy, 4.5 parts of dialkoxy type coupling agent, 3.6 parts of epoxy modified silicone resin, 1.5 parts of silicone, 1.5 parts of phosphate salt, 5 parts of talc, 11 parts Iron red powder, 34 parts xylene and high boiling point aromatic hydrocarbon solvent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com