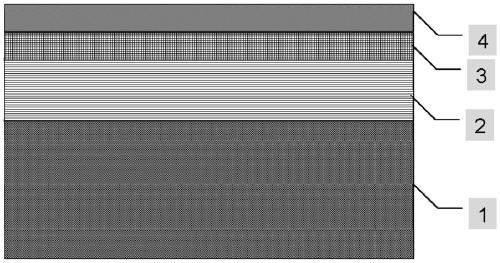

A wear-resistant and anti-friction composite coating for a lip-shaped oil seal rotating shaft and its preparation method

A composite coating, rotating shaft technology, applied in the direction of coating, metal material coating process, superimposed layer plating, etc., can solve the increasingly stringent requirements of lip-shaped oil seal rotating shaft wear resistance and friction reduction performance, There are no problems such as the inherent lubricity of electroplating hard chromium and the low ductility of super-hard coatings, and the effects of simple and reliable preparation method, less environmental pollution and obvious anti-friction effect are achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The embodiment of the present invention provides a preparation method of the above-mentioned wear-resistant and anti-friction composite coating for the rotating shaft of the lip-shaped oil seal, including:

[0033] After degreasing and degreasing the base body of the rotating shaft, perform sandblasting on the spraying position. Sand blasting can remove the oxide layer on the surface of the substrate to increase surface activity and improve the bonding strength between the coating and the substrate. The grit materials used in sand blasting can be white corundum, brown corundum or zirconium corundum, and the grit size of the grit materials can be 46#, 54# or 60#. For reference, during the blasting process, the blasting pressure can be controlled at 0.2-0.5 MPa, and the blasting distance can be controlled at 100-300 mm. The axial direction of the nozzle of the sandblasting machine maintains an angle of 70° to 90° with the surface of the sample. After sandblasting, the su...

Embodiment 1

[0048] This embodiment provides a wear-resistant and anti-friction composite coating for a lip-shaped oil seal rotating shaft and a preparation method thereof, including:

[0049] 1. After degreasing and degreasing the TC4 titanium alloy sample of Φ57mm, perform sandblasting on the sprayed surface. The sand material is 54# white corundum. The sandblasting pressure is controlled at 0.24MPa, the spray distance is 180mm, and the angle is 75°. The sample after sandblasting The surface roughness is uniform, and the residual sand particles on the surface are blown away with compressed air.

[0050] 2. The WC10Co4Cr coating is sprayed with air-assisted combustion supersonic flame, the powder particle size is 5-25μm, the compressed air pressure is 0.59MPa, the propylene pressure is 0.50MPa, the hydrogen flow rate is 32L / min, the nitrogen flow rate is 33L / min, and the powder feeding rate is 70g / min. min, spray distance 175mm, turntable speed 240rpm, spray gun moving speed 20mm / s, coati...

Embodiment 2

[0057] This embodiment provides a wear-resistant and anti-friction composite coating for a lip-shaped oil seal rotating shaft and a preparation method thereof, including:

[0058] 1. After degreasing and degreasing the Φ80mm 7075 aluminum alloy sample, perform sand blasting on the sprayed surface. The sand grain material is 60# zirconium corundum. The sand blasting pressure is controlled at 0.26MPa, the spray distance is 200mm, and the angle is 80°. The sample after sand blasting The surface roughness is uniform, and the residual sand particles on the surface are blown away with compressed air.

[0059] 2. The WC10Co4Cr coating is sprayed with air-assisted combustion supersonic flame, the powder particle size is 10-30μm, the compressed air pressure is 0.61MPa, the propylene pressure is 0.52MPa, the hydrogen flow rate is 33L / min, the nitrogen flow rate is 34L / min, and the powder feeding rate is 110g / min. min, spray distance 185mm, turntable speed 200rpm, spray gun moving speed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com