A light-controlled neurosynaptic bionic electronic device and its preparation method

A technology of electronic devices and neural synapses, applied in electrical components, semiconductor devices, circuits, etc., can solve the problems of non-controllability, slow response, storage continuity, poor stability, etc., to achieve easy control, improve stability, low The effect of power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

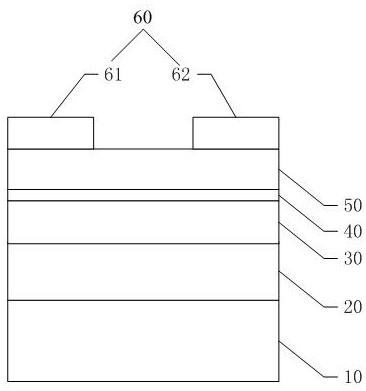

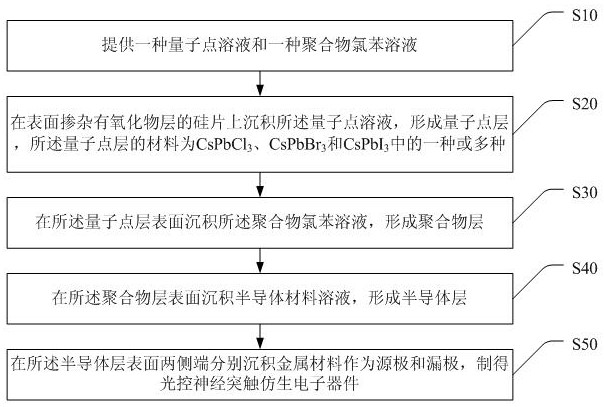

[0049] Based on the above-mentioned light-controlled synaptic bionic electronic device, the present invention also provides a preparation method of a light-controlled synaptic bionic electronic device, wherein, as figure 2 shown, including steps:

[0050] S10, providing a quantum dot solution and a polymer chlorobenzene solution;

[0051] S20, depositing the quantum dot solution on a silicon wafer doped with an oxide layer on the surface to form a quantum dot layer, the material of the quantum dot layer is CsPbCl 3 , CsPbBr 3 and CsPbI 3 one or more of

[0052] S30, depositing the polymer chlorobenzene solution on the surface of the quantum dot layer to form a polymer layer;

[0053] S40, depositing a semiconductor material solution on the surface of the polymer layer to form a semiconductor layer;

[0054] S50. Depositing metal materials on both sides of the surface of the semiconductor layer as source and drain respectively, so as to prepare a bionic electronic device ...

Embodiment 1

[0069] Fully mix cesium carbonate, octadecene and oleic acid in a nitrogen glove box, and heat to 150°C until the reaction is complete to form a cesium oleate solution;

[0070] Then mix lead chloride and octadecene fully and heat to 120°C, inject oleylamine and oleic acid in sequence, heat to 160°C after completely mixing and dissolving, then inject cesium oleate at 100°C, cesium oleate and chloride The molar ratio of lead is 5:1, ice bath after 5 seconds of reaction;

[0071] Using ethanol to make the prepared CsPbCl 3 Quantum dots were precipitated and redispersed in n-hexane solution to obtain inorganic halogen perovskite fluorescent quantum dots CsPbCl 3 solution.

[0072] Spin-coating CsPbCl on Si substrate doped with SiO2 3Quantum dot solution, followed by annealing at 100°C for 1h to form CsPbCl 3 quantum dot layer;

[0073] In CsPbCl 3 spin-coating polymethyl methacrylate solution on the quantum dot layer to form a polymer layer;

[0074] Pentacene organic smal...

Embodiment 2

[0077] Fully mix cesium carbonate, octadecene and oleic acid in a nitrogen glove box, and heat to 150°C until the reaction is complete to form a cesium oleate solution;

[0078] Then mix lead bromide and octadecene fully and heat to 120°C, inject oleylamine and oleic acid in sequence, heat to 160°C after completely mixing and dissolving, then inject cesium oleate at 100°C, cesium oleate and bromide The molar ratio of lead is 6:1, after 5 seconds of reaction, ice bath;

[0079] Using ethanol to make the prepared CsPbBr 3 Quantum dots were precipitated and redispersed in n-hexane solution to obtain inorganic halogen perovskite fluorescent quantum dots CsPbBr 3 solution.

[0080] Spin-coating CsPbBr on Al2O3-doped Si substrates 3 Quantum dot solution, followed by annealing at 120°C for 70min to form CsPbBr 3 quantum dot layer;

[0081] In CsPbBr 3 Spin coating polystyrene (PS) solution on the quantum dot layer to form a polymer layer;

[0082] Pentacene organic small molec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com