Anti-plant virus seed coating agent and application thereof

A technology of anti-plant virus and antifreeze, applied in the direction of plant growth regulators, applications, disinfectants, etc., can solve the problems of products that have not been commercialized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

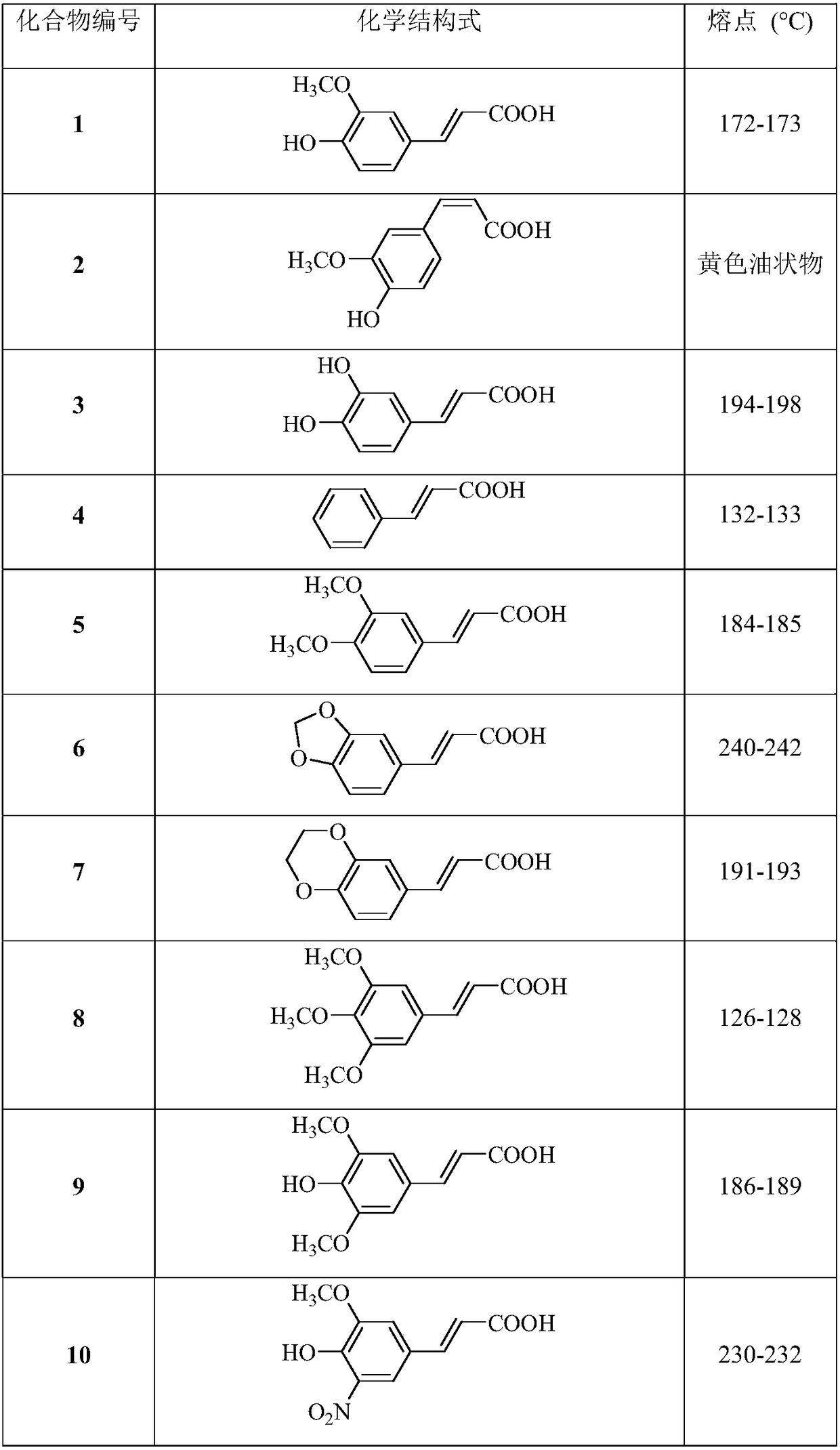

Method used

Image

Examples

Embodiment 1

[0053] Example 1 Preparation of 5% trans-ferulic acid suspension seed coating

[0054] (The following materials must reach a constant weight of water loss) The mass percentage of each component is as follows:

[0055] Trans-ferulic acid 5.1g, xanthan gum 0.3g, sorbic acid 0.5g, polyvinyl alcohol 3g, sodium lignosulfonate 5g, glycerin 2g, potassium fulvic acid 2g, silicone oil 0.4g, polyoxyethylene fatty alcohol ether 2g, 0.2g acetic acid, 5g acid fuchsin, 74.5g water; the total amount is 100g.

[0056] Production: 1) Weigh 64.5g of water, then add 5g of dispersant sodium lignosulfonate, 2g of polyoxyethylene fatty alcohol ether, and 0.2g of acetic acid. After fully dissolving, add 5.1g of trans-ferulic acid technical, and then add poly 3g of vinyl alcohol, 2g of glycerin, 0.5g of sorbic acid, 2g of potassium fulvic acid, 0.4g of silicone oil, and 5g of acid fuchsin are mixed thoroughly. 2) Add 0.3g of xanthan gum slowly to the remaining 10g of water while stirring to prepare the xa...

Embodiment 2

[0057] Example 2 Preparation of 20% trans-ferulic acid suspension seed coating

[0058] (The following materials must reach a constant weight of water loss) The mass percentages of each component are as follows: trans ferulic acid 20.3g, xanthan gum 0.2g, sorbic acid 0.5g, polyvinyl alcohol 3g, sodium lignosulfonate 5g , Polyoxyethylene fatty alcohol ether 2g, glycerin 2g, potassium fulvic acid 2g, silicone oil 0.4g, acid fuchsin 5g, acetic acid 0.5g, water 59.1g; the total amount is 100g.

[0059] Production: 1) Weigh 49.1g of water, then add 5g of dispersant sodium lignosulfonate, 2g of polyoxyethylene fatty alcohol ether, and 0.5g of acetic acid. After fully dissolving, add 20.3g of trans-ferulic acid technical, and then add poly Vinyl alcohol 3g, glycerin 2g, sorbic acid 0.5g, potassium fulvic acid 2g, silicone oil 0.4g, acid fuchsin 5g, mix well. 2) Add 0.2g of xanthan gum slowly to the remaining 10g of water while stirring to prepare the xanthan gum mother liquor, then add i...

Embodiment 3

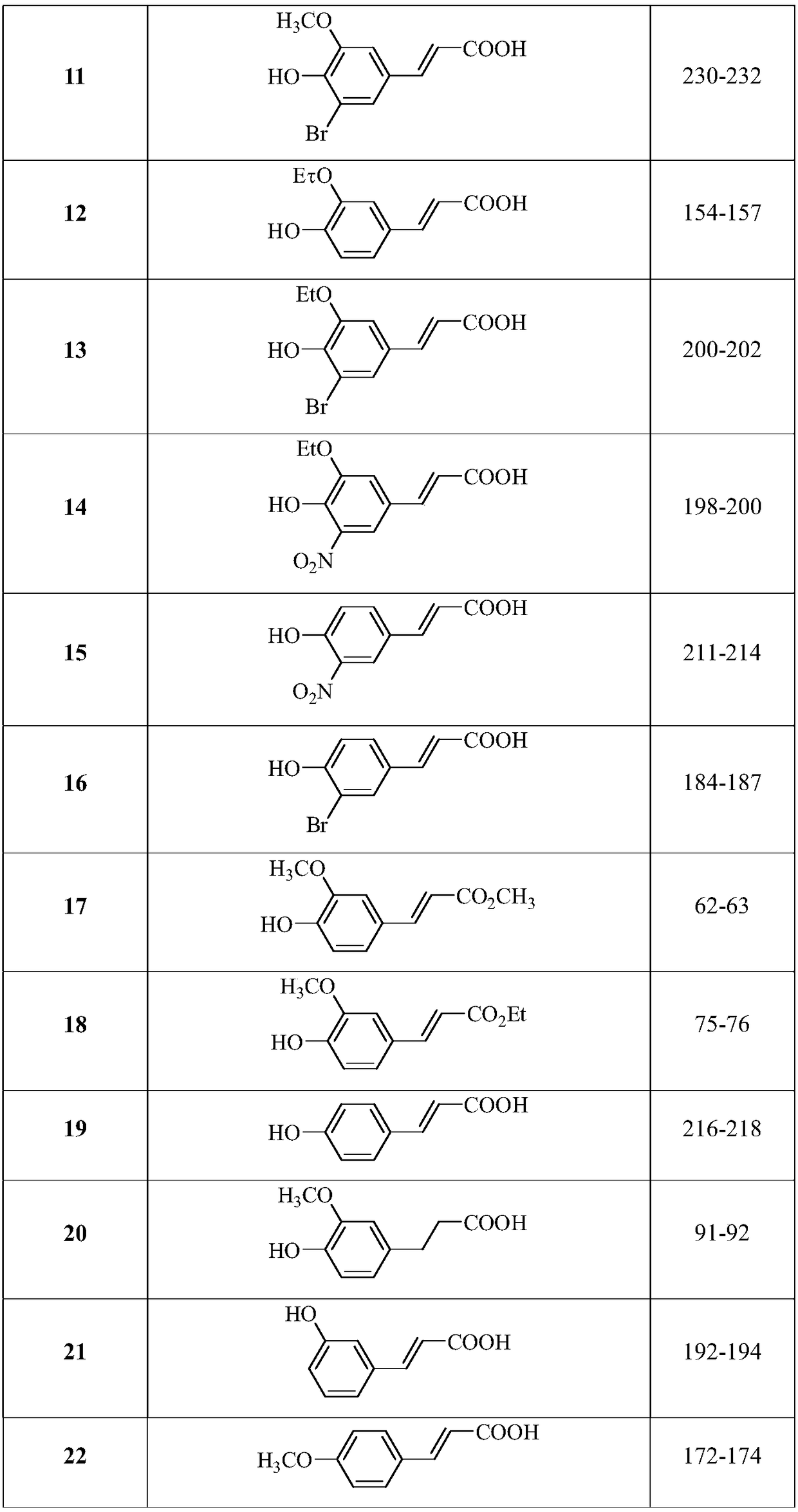

[0060] Example 3 Preparation of 5% trans-ferulic acid derivative (25) suspension seed coating

[0061] (The following materials must reach a constant weight of water loss) The mass percentages of each component are as follows: trans-ferulic acid derivative 5.1g, xanthan gum 0.3g, sorbic acid 0.5g, polyvinyl alcohol 3g, lignin sulfonic acid Sodium 5g, polyoxyethylene fatty alcohol ether 2g, glycerin 2g, potassium fulvic acid 2g, silicone oil 0.4g, acid fuchsin 5g, acetic acid 0.2g, water 74.5g; the total amount is 100g.

[0062] The trans-ferulic acid derivative in this example is the 25th numbered derivative in Table 1, and the structural formula is

[0063]

[0064] Production: 1) Weigh 64.5g, then add 5g of dispersant sodium lignosulfonate, 2g of polyoxyethylene fatty alcohol ether, 0.2g of acetic acid, after fully dissolving, add 5.1g of trans-ferulic acid derivative technical, and then add Polyvinyl alcohol 3g, glycerin 2g, sorbic acid 0.5g, potassium fulvic acid 2g, silicone oi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com