Preparation method of modified PVDF ultrafiltration membrane for complexed heavy metal wastewater treatment

A technology for wastewater treatment and ultrafiltration membrane, applied in the field of membrane materials, can solve the problems of reduced membrane water flux, poor membrane hydrophilicity, and low surface energy, and achieve stable and lasting effects, good hydrophilicity, and large specific surface area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

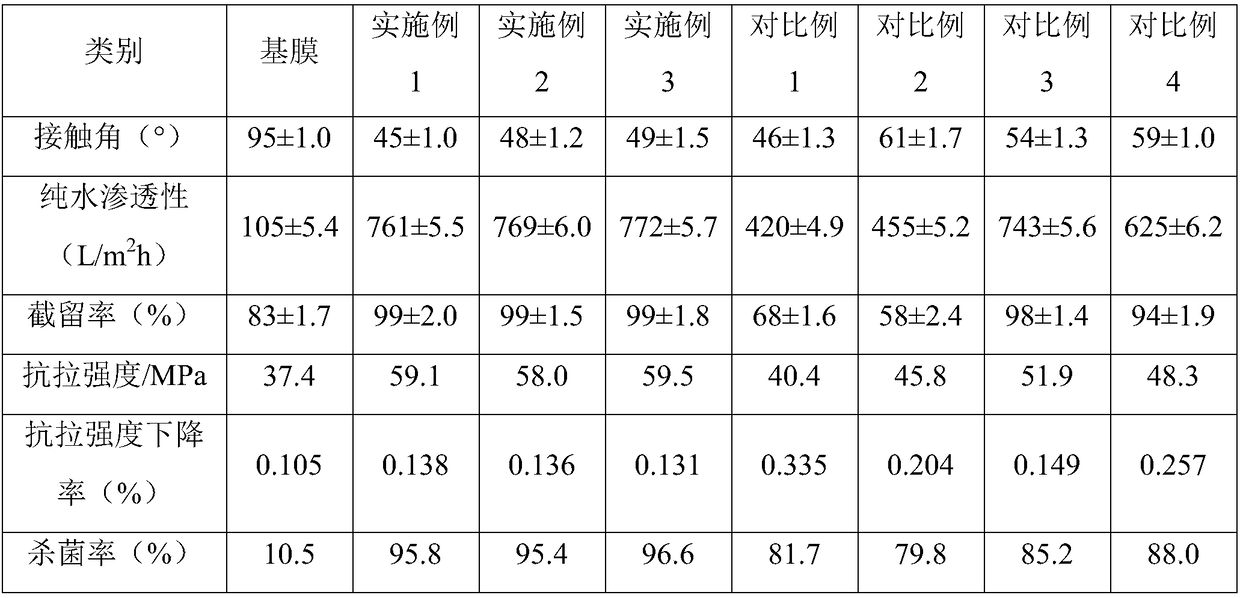

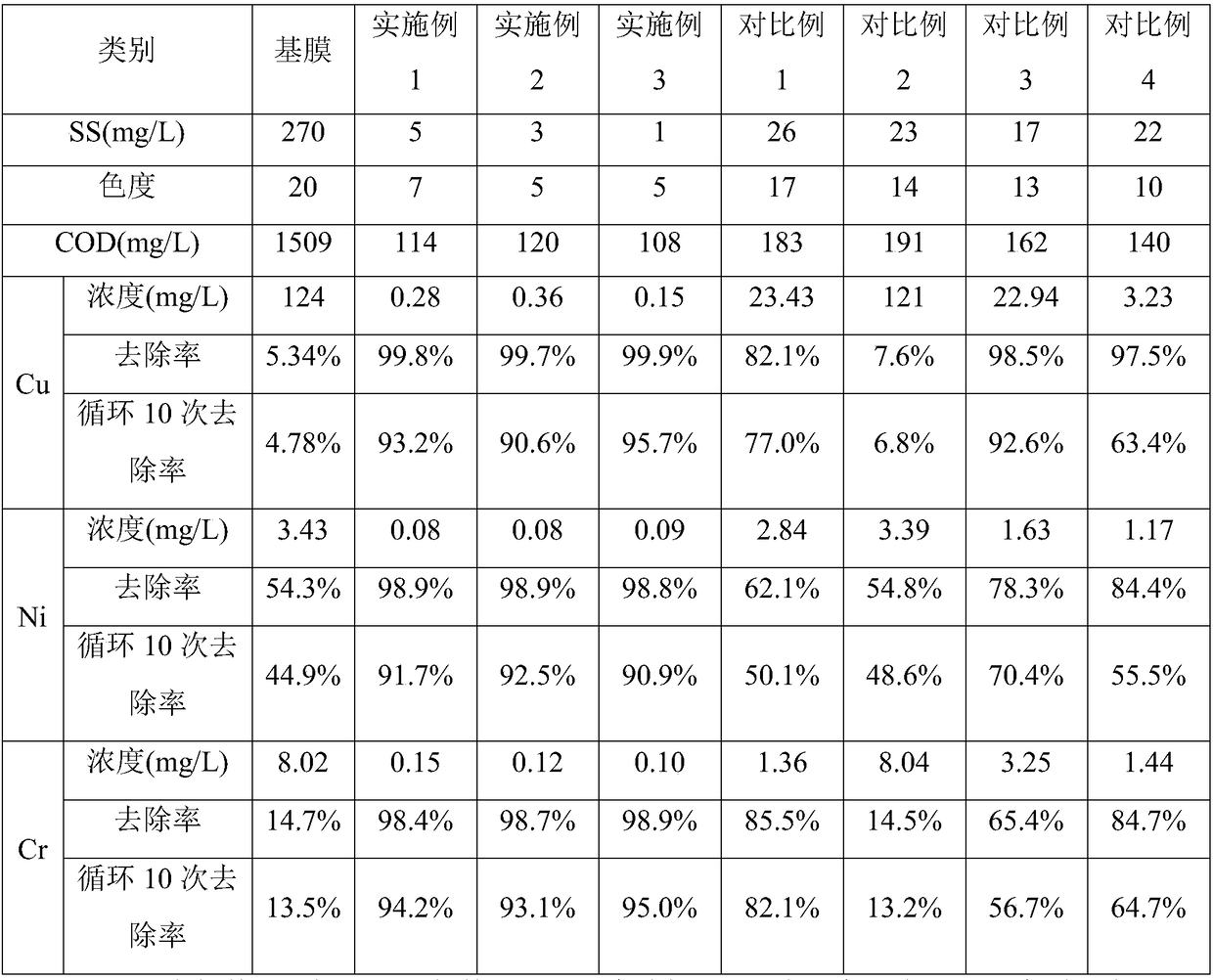

Examples

Embodiment 1

[0027] A method for preparing a modified PVDF ultrafiltration membrane for the treatment of complexed heavy metal wastewater, comprising the following steps:

[0028] 1. Surface grafted PS polymer brush: PVDF ultrafiltration membrane is placed in KOH concentration 2.5mol / L, tetrabutylammonium bromide 3g / L alkali solution, reaction temperature 55 ℃, reaction time 8min, the surface of the basement membrane gets carbon Carbon double bond, the treated PVDF ultrafiltration membrane is soaked in a PS monomer solution with a concentration of 1mol / L for 1h, taken out and washed off the excess solution, and put into a reaction system containing cross-linking agent MBAA and initiator for constant temperature reaction for 20min. The mass ratio of PS monomer to crosslinking agent is 10:0.3, and the PVDF ultrafiltration membrane with PS polymer brushes grafted on the surface is obtained;

[0029] 2. PPy coating: weigh FeCl 3 ·6H 2 Dissolve O in ultrapure water, soak the PVDF ultrafiltrat...

Embodiment 2

[0033] A method for preparing a modified PVDF ultrafiltration membrane for the treatment of complexed heavy metal wastewater, comprising the following steps:

[0034] 1. Surface grafted PS polymer brush: PVDF ultrafiltration membrane is placed in KOH concentration 2.5mol / L, tetrabutylammonium bromide 3.5g / L alkali solution, reaction temperature 60 ℃, reaction time 10min, the surface of the basement membrane is obtained Carbon-carbon double bond, the treated PVDF ultrafiltration membrane is soaked in a PS monomer solution with a concentration of 1.5mol / L for 1 hour, taken out to wash off the excess solution, and put into a reaction system containing a crosslinking agent MBAA and an initiator for constant temperature reaction 30min, the mass ratio of PS monomer and cross-linking agent is 10:0.5, obtains the PVDF ultrafiltration membrane that the surface is grafted with PS polymer brush;

[0035] 2. PPy coating: weigh FeCl 3 ·6H 2 Dissolve O in ultrapure water, soak the PVDF ul...

Embodiment 3

[0039] A method for preparing a modified PVDF ultrafiltration membrane for the treatment of complexed heavy metal wastewater, comprising the following steps:

[0040] 1. Surface grafted PS polymer brush: PVDF ultrafiltration membrane is placed in KOH concentration 2.5mol / L, tetrabutylammonium bromide 4g / L alkali solution, reaction temperature 65 ℃, reaction time 8min, the surface of the basement membrane gets carbon Carbon double bond, the treated PVDF ultrafiltration membrane is soaked in a PS monomer solution with a concentration of 2mol / L for 1h, taken out and washed off the excess solution, and put into a reaction system containing cross-linking agent MBAA and initiator for constant temperature reaction for 35min. The mass ratio of PS monomer to crosslinking agent is 10:0.7, and the PVDF ultrafiltration membrane with PS polymer brushes grafted on the surface is obtained;

[0041] 2. PPy coating: weigh FeCl 3 ·6H 2 Dissolve O in ultrapure water, soak the PVDF ultrafiltrat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com