Light fiber composite plate and production method thereof

A composite board and lightweight fiber technology, applied in the field of building materials, can solve the problems of insufficient water resistance of polyvinyl alcohol, and achieve the effects of overcoming insufficient water resistance, low cost, and resource saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

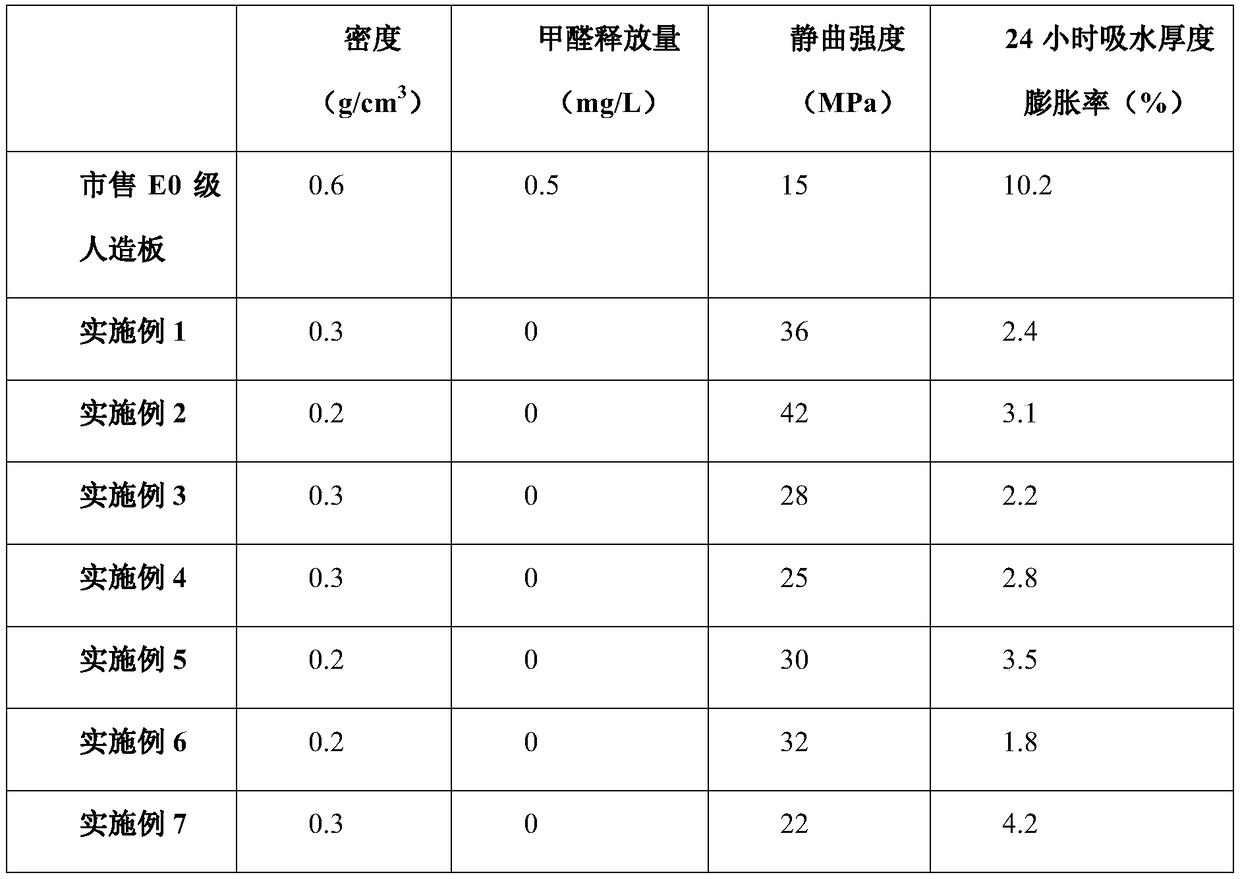

Examples

Embodiment 1

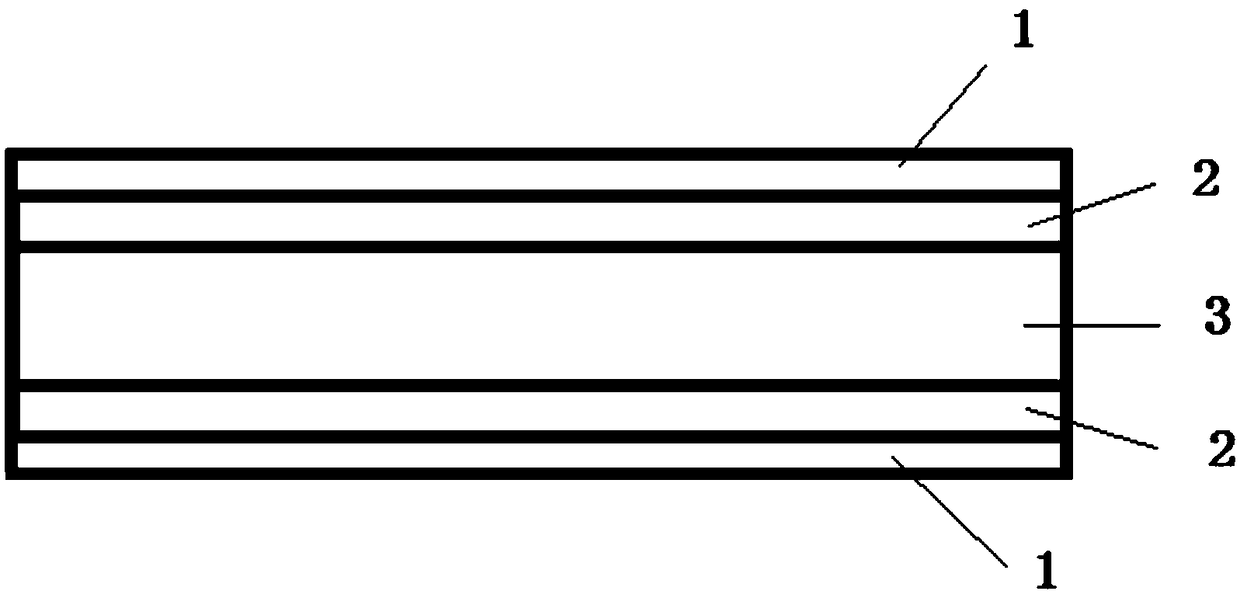

[0040] A light-weight fiber composite board, the board structure is the facing layer 1, the reinforcement layer 2, the core material 3; the core material 3 is obtained by molding the corn stalk fiber with the silicone modified polyvinyl alcohol adhesive. The weight of the vinyl alcohol adhesive is 0.4 times the fiber weight; the silicone-modified polyvinyl alcohol adhesive is a compound of 3-(2,3-glycidoxypropyl)trimethoxysilane and an aqueous solution of polyvinyl alcohol. In the adhesive The weight percentage of polyvinyl alcohol is 15%, the weight percentage of 3-(2,3-glycidoxypropyl)trimethoxysilane is 15%, and the weight percentage of water is 70%; the reinforcing layer 2 is epoxy resin The adhesive is made by bonding gauze to the surface of the core material 3; the facing layer 1 is wood grain melamine impregnated paper.

[0041] A production method of lightweight fiber composite board is as follows:

[0042] (1) First mix the adhesive and fiber uniformly, then pre-dry to re...

Embodiment 2

[0046] A light-weight fiber composite board, the board structure is the facing layer 1, the reinforcement layer 2, the core material 3; the core material 3 is obtained by bonding waste textile fibers with a silicone modified polyvinyl alcohol adhesive. The weight of the vinyl alcohol adhesive is 1 times the fiber weight. The silicone-modified polyvinyl alcohol adhesive is a mixture of silicone-acrylic emulsion and polyvinyl alcohol aqueous solution. The weight percentage of polyvinyl alcohol in the adhesive is 10%, and the weight of the silicone-acrylic emulsion The percentage is 5%, and the weight percentage of water is 85%; the reinforcing layer 2 is made by bonding the non-woven fabric to the surface of the core material with epoxy resin adhesive; the facing layer 3 is aluminum foil.

[0047] A production method of lightweight fiber composite board is as follows:

[0048] (1) First mix the adhesive and fiber uniformly, then pre-dry to remove most of the water;

[0049] (2) Then p...

Embodiment 3

[0052] A light-weight fiber composite board. The structure of the board is a facing layer 1, a reinforcement layer 2, and a core material 3. The core material 3 is obtained by molding and pressing rice straw fibers with a silicone modified polyvinyl alcohol adhesive. The weight of the vinyl alcohol adhesive is 1.5 times the fiber weight; the silicone modified polyvinyl alcohol adhesive is a combination of 3-aminopropyltriethoxysilane and polyvinyl alcohol aqueous solution, and the weight percentage of the polyvinyl alcohol in the adhesive is 5 %, the weight percentage of 3-aminopropyltriethoxysilane is 3%, and the weight percentage of water is 92%; the reinforcement layer 2 is made of epoxy resin adhesive bonding gauze to the surface of the core material 3; the facing layer 1 is aluminum foil.

[0053] A production method of lightweight fiber composite board is as follows:

[0054] (1) First mix the adhesive and fiber uniformly, then pre-dry to remove most of the water;

[0055] (2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com