Preparation methods of pyridine nitrogen enriched ultrathin carbon nanosheet material and metal composite of pyridine nitrogen enriched ultrathin carbon nanosheet material

A carbon nanosheet, pyridine nitrogen technology, applied in nanocarbon, nanotechnology, nanotechnology and other directions, to achieve high stability, overcome poor electrical conductivity, and improve the effect of electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] A preparation method of pyridine nitrogen enriched ultra-thin carbon nanosheet material, the method comprising the following steps:

[0054] (1) Mixing of raw materials: 19g, 0.8g, 19g, 0.8g, After mixing 0.1g and 0.1g, add 40mL of deionized water to dissolve, stir and mix evenly under the condition of heating in a water bath, and place in an oven for 40-48 hours to obtain a light yellow solid mixture;

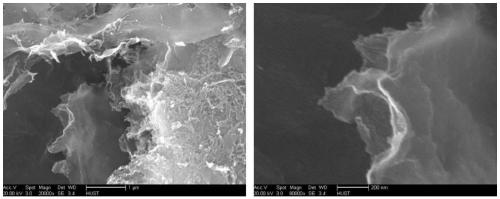

[0055] (2) Pyrolysis reaction: Grind the light yellow solid mixture obtained in step (1) into a uniform powder, react in a tube furnace, use nitrogen as a protective gas, and start from room temperature (25 ° C) at 5 ° C / The temperature was raised to 600 °C at a rate of 1 min and kept for 1 h, and then raised to 700 °C at a rate of 5 °C / min and kept for 1 h to obtain a black powdery solid that is a nanosheet material enriched with pyridine nitrogen. figure 1 It is a scanning electron micrograph of the ultra-thin pyridine nitrogen-rich nanosheet material prepared in t...

Embodiment 2

[0058] A preparation method of pyridine nitrogen enriched ultra-thin carbon nanosheet material, the method comprising the following steps:

[0059] (1) Mixing of raw materials: Melamine, GAH (D-glucosamine hydrochloride) 2-methylimidazole and pyromellitic anhydride were mixed with 10g, 0.8g, After mixing 0.1g and 0.1g, add 40mL of deionized water to dissolve, stir and mix evenly under the condition of heating in a water bath, and dry in an oven for about 48 hours to obtain a light yellow solid mixture.

[0060] (2) Pyrolysis reaction: Grind the solid mixture into a fine and uniform powder, react in a tube furnace, use nitrogen as a protective gas, and raise the temperature from room temperature to 600°C at a rate of 5°C / min and keep it for 1h. Then the temperature was raised to 700° C. at a rate of 5° C. / min and kept for 1 h to obtain a black powdery solid that was an ultrathin pyridine nitrogen-enriched nanosheet material. Figure 7 The scanning electron micrograph of the ul...

Embodiment 3

[0063] A preparation method of pyridine nitrogen enriched ultra-thin carbon nanosheet material, the method comprising the following steps:

[0064] (1) Mixing of raw materials: Melamine, GAH (D-glucosamine hydrochloride) 2-methylimidazole and pyromellitic anhydride were mixed with the above reactants 40, 0.8g, After mixing 0.1g and 0.1g, add 40mL of deionized water to dissolve, stir and mix evenly under the condition of heating in a water bath, and dry in an oven for about 48 hours to obtain a light yellow solid mixture.

[0065] (2) Pyrolysis reaction: Grind the solid mixture into a fine and uniform powder, react in a tube furnace, use nitrogen as a protective gas, and raise the temperature from room temperature to 600°C at a rate of 5°C / min and keep it for 1h. Then the temperature was raised to 700° C. at a rate of 5° C. / min and kept for 1 h to obtain a black powdery solid that was an ultrathin pyridine nitrogen-enriched nanosheet material. Figure 8 The scanning electron m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com