Purifying technology of potassium feldspar sand powder

A technology for potassium feldspar and stone sand powder, which is applied in the field of deep processing of potassium feldspar, can solve the problems such as whiteness to be improved, high cost of impurity removal, generation of waste acid, etc., and achieves easy separation and collection of impurities, good purification effect, The effect of improving purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

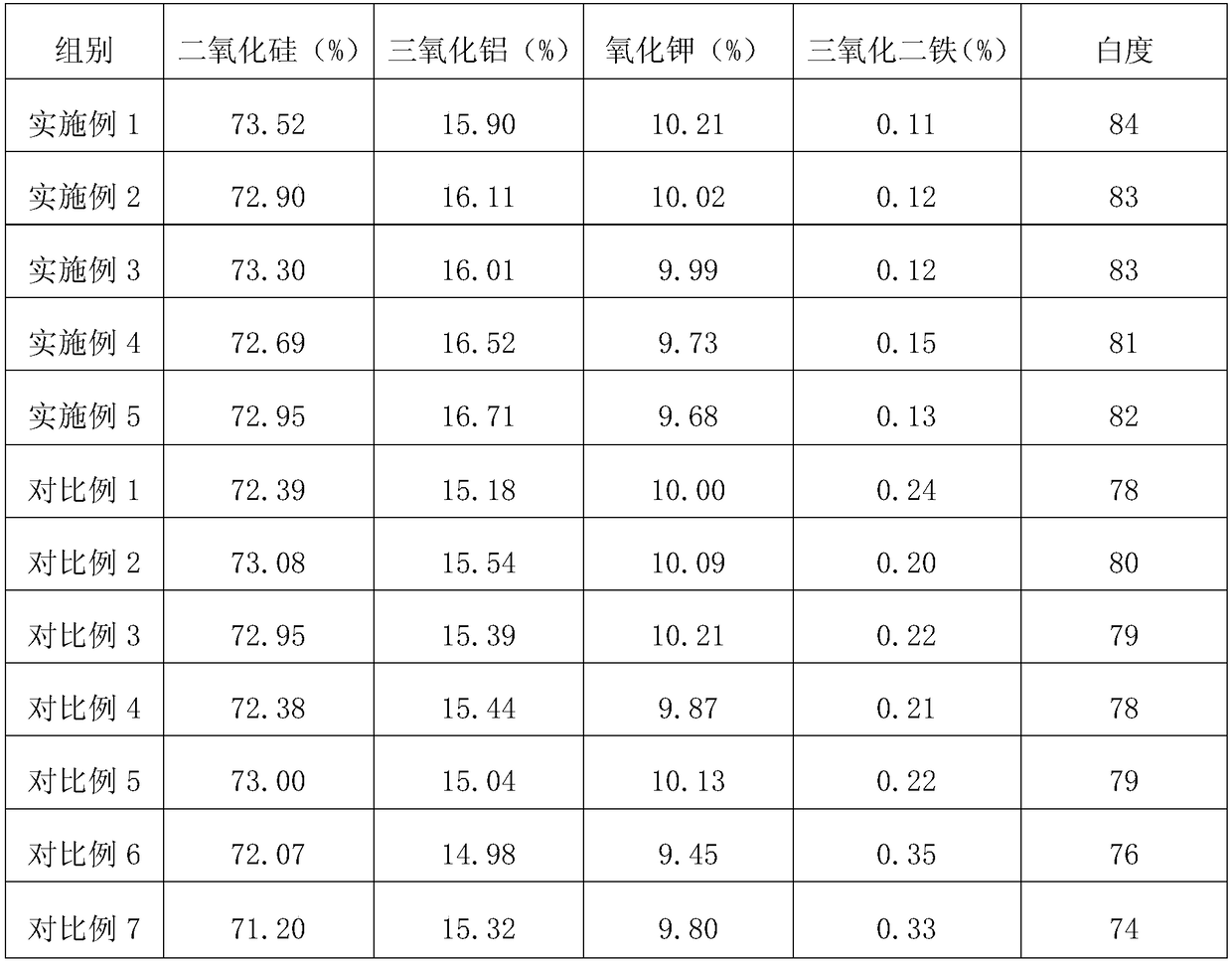

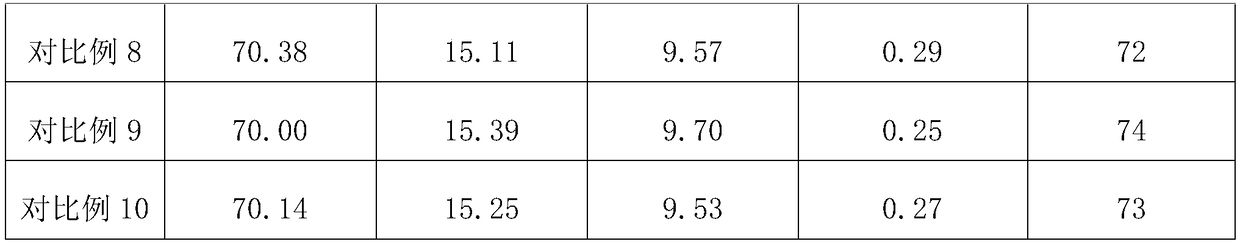

Examples

Embodiment 1

[0034] The purification process of potassium feldspar sand powder comprises the following steps:

[0035] S1. Add 200 mesh potassium feldspar sand powder into water, the solid-to-liquid ratio is 1:0.9, mix well to obtain a slurry, and add the following agents to the slurry for purification: add water glass and stir for 15 minutes, and keep the temperature at 80°C; Add nitrilotriacetic acid and stir for 8 minutes, and keep the temperature at 72°C (after the temperature drops to the set temperature, which is 72°C, then add the medicament, the same below); add sodium benzoate and sodium hydroxymethylcellulose and stir for 7 minutes, and keep the temperature at 70°C; Then mixed slurry is transferred in the high-voltage electric pulse device, through high-voltage electric pulse treatment, the electric pulse frequency of high-voltage electric pulse treatment process is 55Hz, electric field strength is 45kv, and pulse processing time is 2min; Add octylamine and Sodium dodecylbenzenes...

Embodiment 2

[0045] The purification process of potassium feldspar sand powder comprises the following steps:

[0046] S1. Add 200 mesh potassium feldspar sand powder into water, the solid-to-liquid ratio is 1:0.8, mix well to obtain a slurry, and add the following agents to the slurry for purification: add water glass and stir for 12 minutes, and keep the temperature at 85°C; Add nitrilotriacetic acid and stir for 6 minutes, keeping the temperature at 75°C; add sodium benzoate and sodium hydroxymethylcellulose and stir for 7 minutes, keeping the temperature at 75°C; Treatment, the electric pulse frequency of the high-voltage electric pulse treatment process is 50Hz, the electric field strength is 40kv, and the pulse treatment time is 3min; then add octylamine and sodium dodecylbenzenesulfonate and stir for 15min, and the temperature is kept at 58°C;

[0047] The consumption of each described medicament is calculated by every 1000kg of water, specifically as follows:

[0048] Water glass ...

Embodiment 3

[0056] The purification process of potassium feldspar sand powder comprises the following steps:

[0057]S1. Add 200 mesh potassium feldspar sand powder into water, the solid-liquid ratio is 1:1, mix well to obtain a slurry, and add the following agents to the slurry for purification: add water glass and stir for 18 minutes, and the temperature is kept at 78 ℃; Add nitrilotriacetic acid and stir for 8 minutes, and the temperature is kept at 70 °C; add sodium benzoate and sodium hydroxymethyl cellulose and stir for 9 minutes, and the temperature is kept at 65 °C; then the mixed slurry is transferred to a high-voltage electric pulse device. Treatment, the electric pulse frequency of the high-voltage electric pulse treatment process is 60Hz, the electric field intensity is 50kv, and the pulse treatment time is 2min; then add octylamine and sodium dodecylbenzenesulfonate and stir for 25min, and the temperature is kept at 55 ℃;

[0058] The dosage of each medicament, calculated per...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap