Preparation of a fluorine-containing silicone modified anti-graffiti coating

A fluorosilicon modification, anti-graffiti technology, applied in anti-corrosion coatings, anti-fouling/underwater coatings, electrophoretic coatings, etc., can solve problems such as good tank liquid circulation stability, good production efficiency, and unstable tank liquid circulation. , to achieve the effect of good bath stability, good decorative effect, smooth and bright board surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

[0028] Preparation Example 1 Preparation of fluorine-containing organosilicon ring-modified oxyacrylic resin

[0029]

[0030] In a flask with stirring, condenser and dropping funnel, add bisphenol A epoxy resin with epoxy equivalent of 188, polycaprolactone diol, PPG-400, dibutyltin dilaurate, bisphenol A. Methyl isobutyl ketone, heat up to 100°C, add dimethylbenzylamine, continue to heat up to 135°C and stir for 1.5 hours until the epoxy equivalent is 1000±100, add half-blocked polyisocyanate dropwise at 130-140°C After half an hour to complete the dropwise addition, continue to stir for 1 hour, then drop the temperature to 115°C and drop the mixed solution (methyl methacrylate, n-butyl acrylate, styrene, azobisisobutyronitrile, PMTFPS, benzoyl peroxide ), after 3 hours of dropwise addition and heat preservation for half an hour, add propylene glycol monobutyl ether, cool down to 115°C, add N-methylethanolamine, and react at 115°C for 3 hours to obtain a fluorosilicone-mo...

preparation Embodiment 2

[0031] Preparation Example 2 Preparation of blocked aliphatic isocyanate curing agent:

[0032] 25 parts methyl isobutyl ketone

[0033] 40 parts hexamethylene diisocyanate

[0034] 35 parts n-butanol

[0035] Add methyl isobutyl ketone and hexamethylene diisocyanate into a reaction vessel with a stirrer and a condenser according to the formula amount, blow nitrogen, raise the temperature to 75°C, add n-butanol dropwise, finish dropping in 1 hour, and keep warm After 2 hours, cool down to below 45°C and discharge to obtain the blocked aliphatic isocyanate curing agent.

preparation Embodiment 3

[0036] Preparation Example 3 Preparation of Fluorosilicone Modified Emulsion

[0037]

[0038] Add the fluorosilicone-modified cyclopropane resin and the blocked aliphatic isocyanate curing agent into the reaction vessel according to the formula quantity and stir for 1 hour to mix evenly, then add the neutralizer (lactic acid and sulfamic acid are dissolved in deionized water in advance) and stir After 1 hour, deionized water was added to the reaction vessel at one time and stirred at high speed for 2 hours. The temperature of the reaction vessel was controlled below 45° C. during the whole preparation process to obtain the fluorosilicon modified emulsion.

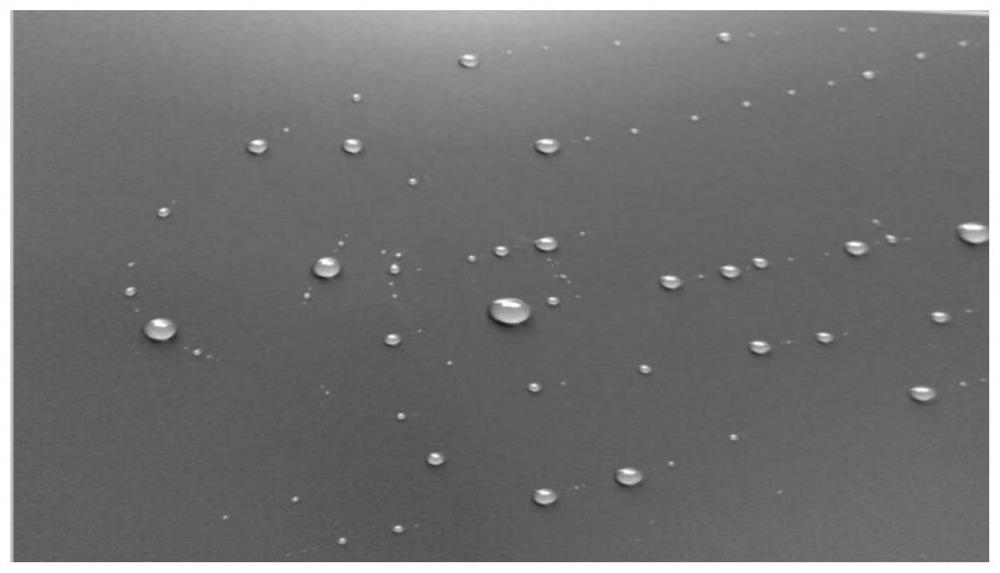

[0039]The fluorosilicon modified emulsion obtained in the above example 3 is matched with the HLS high-performance black slurry according to 6:1 to form an electrophoresis tank solution with a solid content of 12%, and it is matured in the electrophoresis tank for 24 hours. The electrophoresis voltage is 160V, and the te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com