A method for preparing near-infrared second-region fluorescent silver sulfide quantum dots in aqueous phase

A water-phase preparation, near-infrared technology, applied in chemical instruments and methods, luminescent materials, nano-optics, etc., can solve the problems of low fluorescence quantum yield of quantum dots, difficult to guarantee colloidal stability, etc. Short cycle times and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

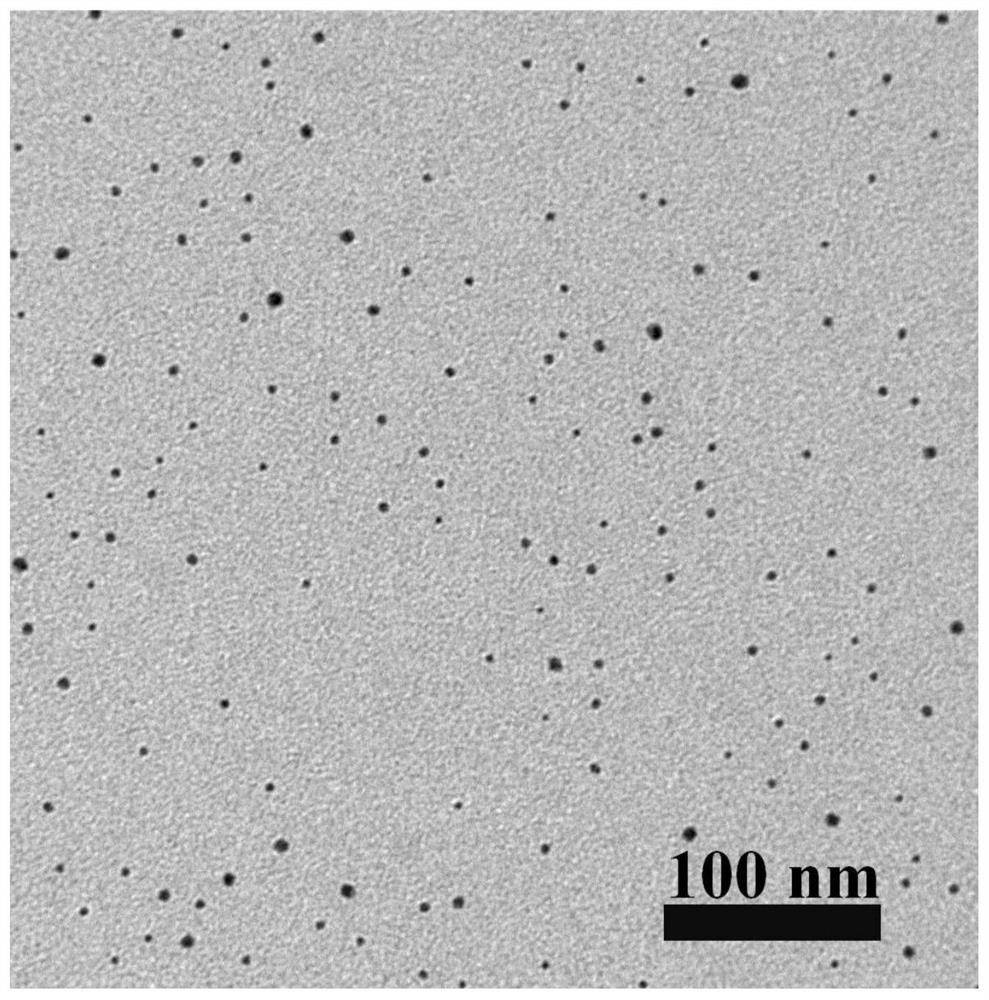

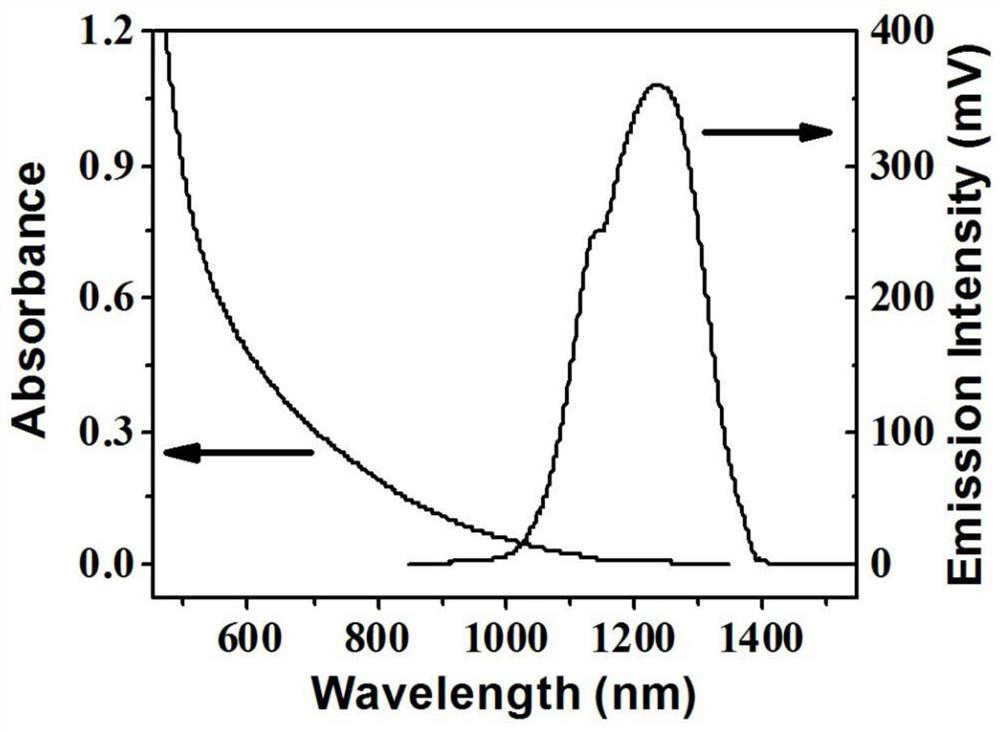

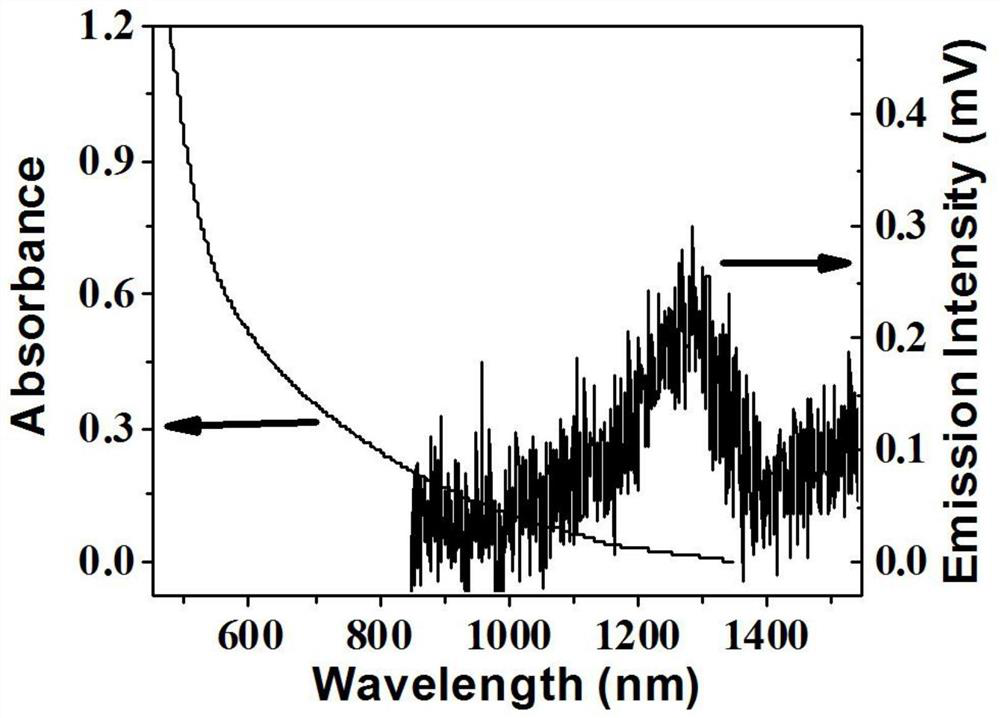

[0025] A method for preparing fluorescent silver sulfide quantum dots in the second near-infrared region in an aqueous phase, comprising the following steps:

[0026] Step 1: Add the cationic surfactant into the water and heat it until it is completely dissolved, then lower the aqueous solution of the cationic surfactant to (25-35)°C; wherein the cationic surfactant is cetyltrimethylammonium bromide ; The concentration of cationic surfactant is 1.1mM;

[0027] Step 2: Slowly add sodium sulfide solution into the cationic surfactant aqueous solution obtained in step 1 and stir evenly, then add silver nitrate solution and stir evenly; wherein, the molar ratio of sodium sulfide and silver nitrate is 0.45:1; vulcanization The concentration of sodium is 0.9mM;

[0028] Step 3: Heat the solution obtained in Step 2 to 90°C and react for 30 minutes to obtain an aqueous solution of fluorescent silver sulfide quantum dots in the second near-infrared region.

[0029] The advantages of t...

specific Embodiment 2

[0032] A method for preparing fluorescent silver sulfide quantum dots in the second near-infrared region in an aqueous phase, comprising the following steps:

[0033] Step 1: Add the cationic surfactant into the water and heat it until it is completely dissolved, then lower the aqueous solution of the cationic surfactant to (25-35)°C; wherein the cationic surfactant is cetyltrimethylammonium bromide ; The concentration of cationic surfactant is 100mM;

[0034] Step 2: Slowly add sodium sulfide solution into the cationic surfactant aqueous solution obtained in step 1 and stir evenly, then add silver nitrate solution and stir evenly; wherein, the molar ratio of sodium sulfide and silver nitrate is 0.45:1; vulcanization The concentration of sodium is 0.9mM;

[0035] Step 3: Heat the solution obtained in Step 2 to 90°C and react for 30 minutes to obtain an aqueous solution of fluorescent silver sulfide quantum dots in the second near-infrared region.

[0036] The advantages of t...

specific Embodiment 3

[0039] A method for preparing fluorescent silver sulfide quantum dots in the second near-infrared region in an aqueous phase, comprising the following steps:

[0040] Step 1: Add the cationic surfactant into the water and heat it until it is completely dissolved, then lower the aqueous solution of the cationic surfactant to (25-35)°C; wherein the cationic surfactant is cetyltrimethylammonium bromide ; The concentration of cationic surfactant is 0.55mM;

[0041] Step 2: Slowly add sodium sulfide solution into the cationic surfactant aqueous solution obtained in step 1 and stir evenly, then add silver nitrate solution and stir evenly; wherein, the molar ratio of sodium sulfide and silver nitrate is 0.45:1; vulcanization The concentration of sodium is 0.9mM;

[0042]Step 3: Heat the solution obtained in Step 2 to 90°C and react for 30 minutes to obtain an aqueous solution of fluorescent silver sulfide quantum dots in the second near-infrared region.

[0043] The advantages of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com