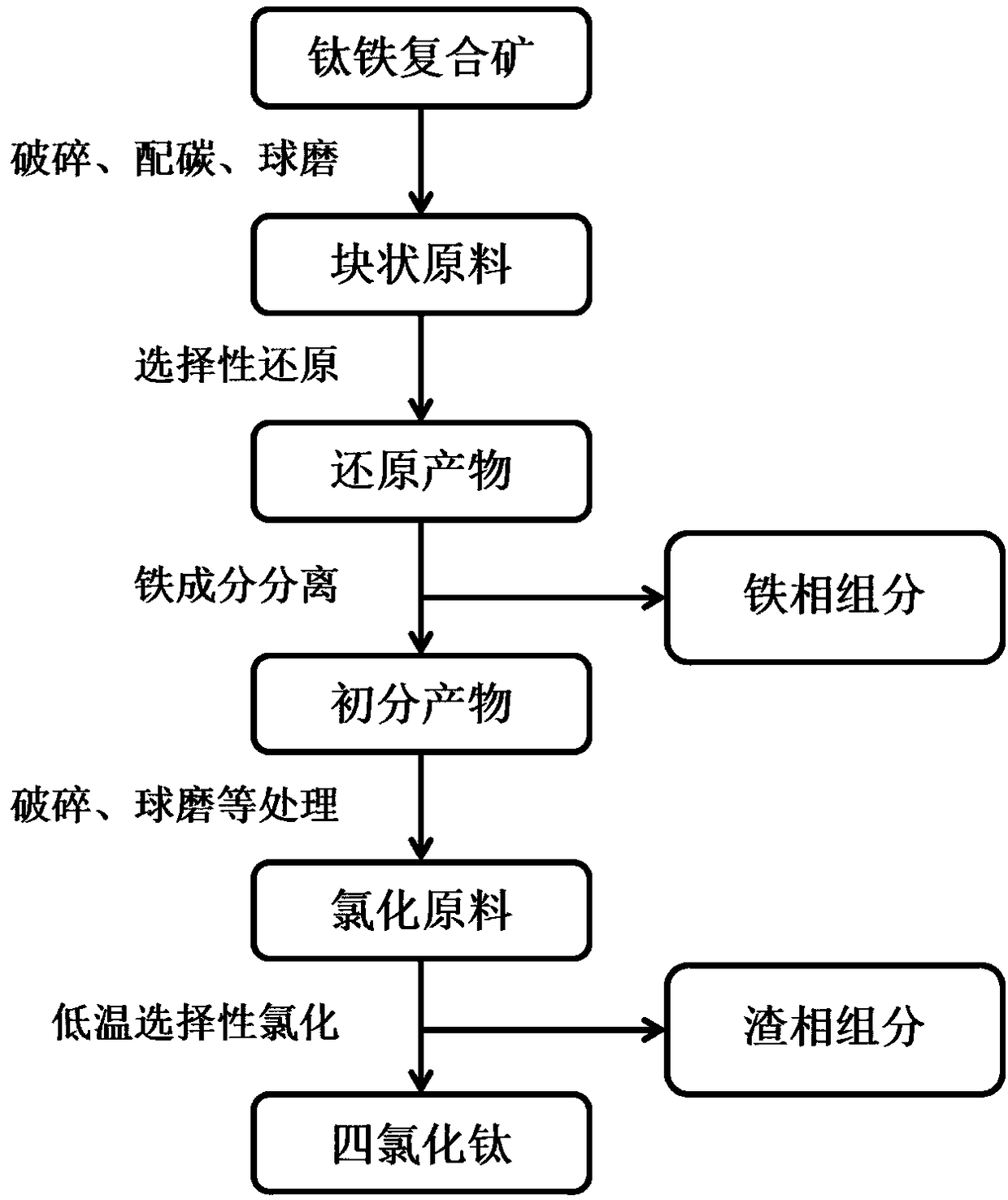

Method for preparing titanium products with ferrotitanium composite ores as raw materials

A technology for composite minerals and raw materials, applied in the chemical industry, can solve the problems of reducing the selectivity of the chlorination process, increasing the economic cost of the process, reducing the efficiency of titanium chlorination, etc. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

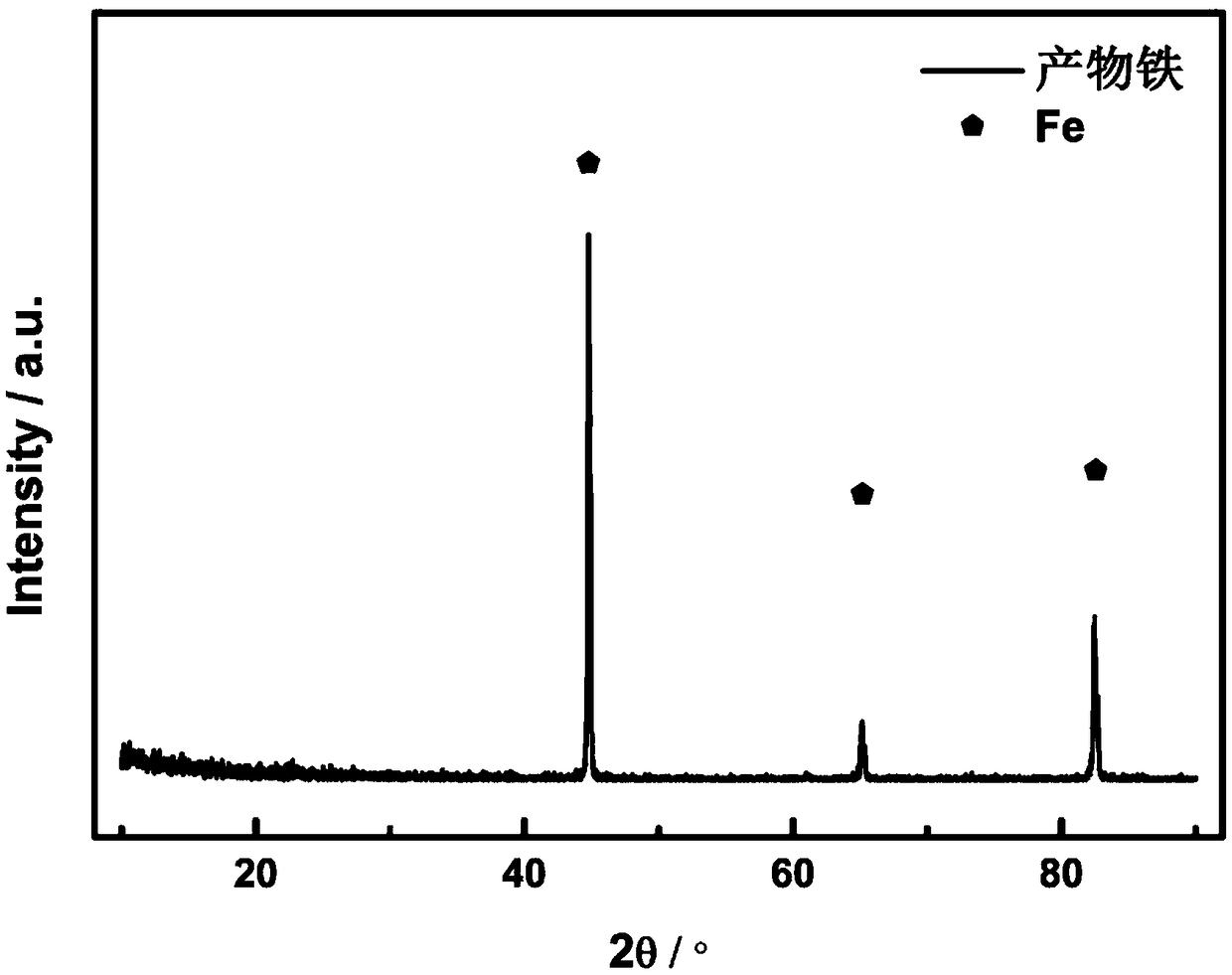

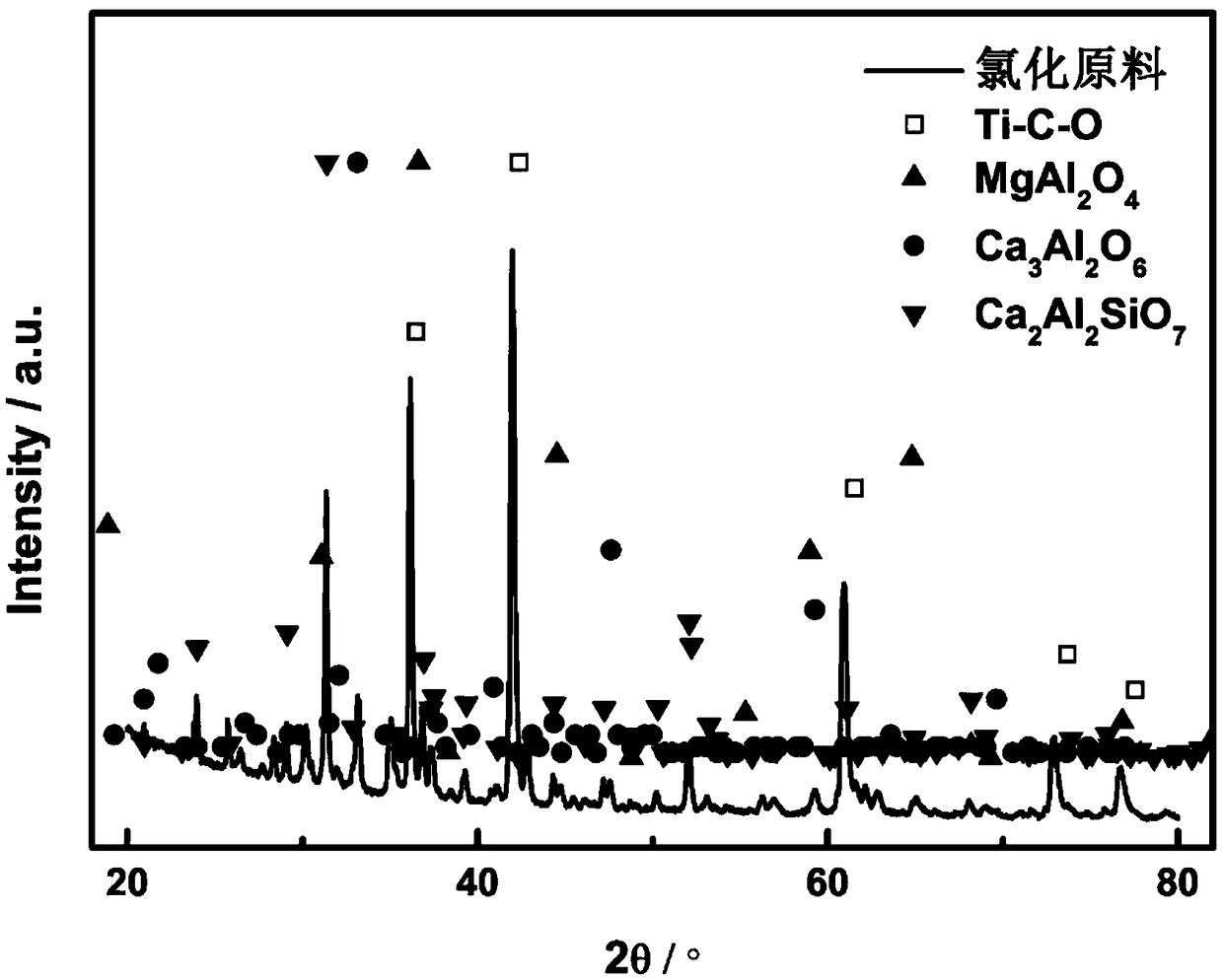

Embodiment 1

[0062] Weigh 200.0g of ilmenite (FeO: 42.7%, TiO 2 : 47.5%), put 42.9g of graphite powder (99.9% of carbon content) into the planetary ball mill and mix evenly. 2000°C, keep warm for 3 hours and then cool to room temperature to obtain a reduced product divided into upper and lower parts. The structure of the lower part is analyzed by X-ray diffraction, as shown in the attached manual. figure 2 As shown, it is the reduction product iron; the structure of the upper part is analyzed by X-ray diffraction, as shown in the attached image 3 shown, titanium carbide (TiC 0.5 o 0.5 , x / z=1) and other mixtures of unreduced oxide components. It can be seen that after carbothermal selective reduction, the iron oxide in the ilmenite composite ore is reduced to metallic iron and deposited on the lower part, and the titanium oxide is reduced to titanium oxycarbide (TiC 0.5 o 0.5 ) and other oxide components (Al 2 o 3 -MgO-CaO-SiO 2 ) is at the top. After the upper block of the redu...

Embodiment 2

[0064] Take by weighing 200.0g high titanium slag (Fe 2 o 3 : 10.5%, TiO 2 : 77.7%), add 48.1g of graphite powder (99.9% of carbon content) and put it in a planetary ball mill to mix evenly. ℃, keep warm for 7 hours and then cool to room temperature to obtain a reduction product divided into upper and lower parts. The reduction product iron is deposited in the lower part, and the structure of the upper part is analyzed by X-ray diffraction. x N y o z , x / z=0.75) and the mixture of unreduced components. After the upper block of the reduction product was crushed and ground to below 200 mesh, it was chlorinated at 400°C. After the reaction was complete, the residue was analyzed by X-ray diffraction. It was other oxide components (Al 2 o 3 -MgO-CaO-SiO 2 ), after further oxidation treatment of the chlorination product, the oxidation product obtained was analyzed by X-ray diffraction as titanium dioxide (TiO 2), composition analysis showed that its purity was 99.1%.

Embodiment 3

[0066] Weigh 200.0g of iron ore concentrate (Fe 2 o 3 : 47.3%, FeO: 29.2%, TiO 2 : 12.4%), mixed with 38.6g graphite powder (99.9% carbon content) and placed in a planetary ball mill to mix evenly. After 5 hours of heat preservation, it was cooled to room temperature, and the X-ray diffraction analysis results of the reduction products showed that after carbon thermal selective reduction, the iron oxides in the ilmenite composite ore were reduced to metallic iron, and the titanium oxides were reduced to carbon and nitrogen. Titanium oxide (TiC x N y o z , x / z=0.5), other components were not reduced. After the upper block of the reduction product was crushed and ground to below 200 mesh, it was chlorinated at 400°C. After the reaction was complete, the residue was analyzed by X-ray diffraction. The results showed that other oxide components (Al 2 o 3 -MgO-CaO-SiO 2 ), after further oxidation treatment of the chlorination product, the oxidation product obtained was analy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com