A doped and coated modified lithium nickel cobalt aluminate cathode material and a preparation method thereof

A technology of lithium nickel cobalt aluminate and lithium nickel cobalt oxide, which is applied in the field of doping and coating modified nickel cobalt lithium aluminate cathode material and its preparation, can solve the problem of limiting the application of ternary cathode materials and the cycle stability of lithium-ion batteries To improve cycle stability and inhibit erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

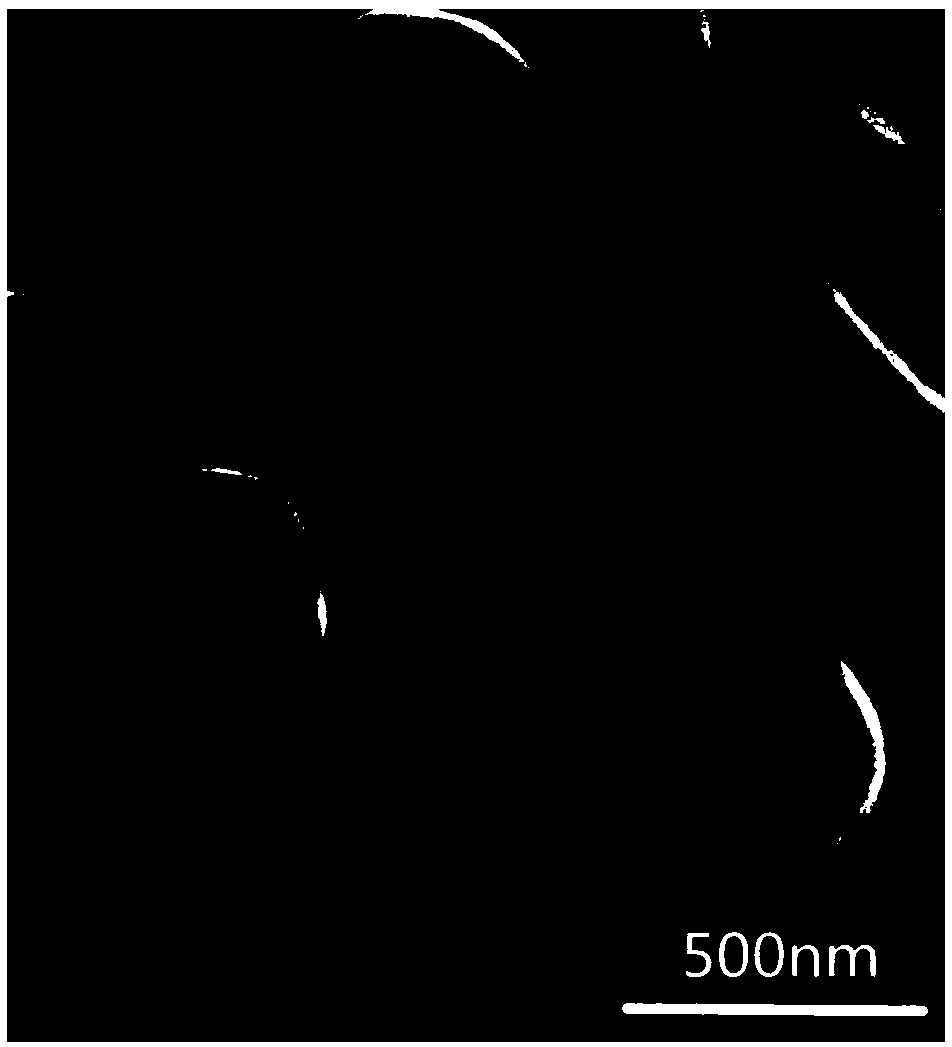

Image

Examples

preparation example Construction

[0035] The present invention also provides a method for preparing a doped and coated modified nickel-cobalt-lithium-aluminate positive electrode material, comprising the following steps:

[0036] (1) providing a titanium coating solution comprising a titanium source and an organic solvent;

[0037] (2) After mixing the titanium coating liquid in the step (1) with the nickel-cobalt-lithium-aluminate precursor, evaporate the organic solvent to obtain the precursor of the mixed titanium source; the nickel-cobalt-lithium-aluminate precursor is Ni 1-x-y co y al x (OH) 2 , where, 0.030≤x≤0.050, 0.100≤y≤0.150;

[0038] (3) The precursor of the mixed titanium source obtained in the step (2) is mixed with a lithium source and a chlorine source for ball milling to obtain a ball mill mixture;

[0039] (4) Under an oxygen atmosphere, pre-sinter and re-sinter the ball-milled mixture obtained in the step (3) to obtain a primary coating doped positive electrode material; the temperature of...

Embodiment 1

[0064] Preparation of cathode material:

[0065] (1) Dissolve tetraisopropyl titanate in 200 mL of absolute ethanol at a molar ratio of titanium source and organic solvent of 1:100, heat and stir at a constant speed for 10 min to prepare a titanium coating solution.

[0066] (2) According to the proportion that tetraisopropyl titanate accounts for the mole fraction of the precursor is 0.05mol%, the NCA precursor (molecular formula Ni 0.815 co 0.15al 0.035 (OH) 2 ) into the stirred titanium coating solution. During the mixing process, the temperature of the solution was controlled at 45°C. After stirring at a constant speed for 3 hours, the temperature was raised to 95°C, kept at 95°C, and the organic solvent was evaporated to dryness to obtain titanium-coated NCA. Precursor.

[0067] (3) Mix the titanium-coated NCA precursor prepared in (2), the lithium source (lithium hydroxide monohydrate) and ammonium chloride uniformly with a ball mill at a speed of 100r / min for 10h to...

Embodiment 2

[0072] The cathode material was prepared according to the method of Example 1, except that the mole fraction of tetraisopropyl titanate in the precursor in step (2) was 0.10 mol%.

[0073] Similarly, the elemental analysis and detection of the obtained positive electrode material shows that the obtained positive electrode material is a doped and coated modified nickel-cobalt lithium aluminate positive electrode material, including a chlorine-doped nickel-cobalt lithium aluminate core body core coating layer. The composition of the chlorine-doped nickel-cobalt-aluminate (NCA) core body is LiNi 0.815 co 0.15 al 0.035 Cl 0.005 o 1.9975 , the components of the cladding layer are PAN and Li 4 Ti 5 o 12 , the molar ratio of the cladding layer to the core body is 0.0010:1, and the PAN and Li in the cladding layer 4 Ti 5 o 12 The molar ratio is 4:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| First discharge specific capacity | aaaaa | aaaaa |

| First discharge specific capacity | aaaaa | aaaaa |

| First discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com