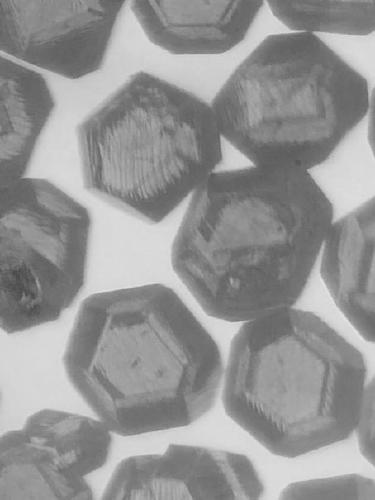

A kind of catalyst alloy powder and its surface grooved diamond prepared by using it, preparation method and application

A technology of diamond and alloy powder, which is used in diamond products and applications, catalyst alloy powder and the preparation of surface groove-shaped diamond by using it, can solve the problem that diamond cannot adapt to high-load working conditions, and the surface is smooth and diamond self-sharpening is not high enough. , can not guarantee the service life and other problems, to achieve the effect of large holding force, increase the proportion and improve the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A method for preparing a surface-grooved diamond, comprising the following steps:

[0023] (1) Preparation of catalyst alloy powder: trace elements of copper, manganese, chromium, niobium and cobalt are added to the iron-based catalyst, and the catalyst alloy powder is composed of the following raw materials in mass percentage: iron 79%, copper 12.5%, manganese 2.5%, chromium 1 %, niobium 1%, cobalt 4%; then made into 250 mesh alloy powder;

[0024] (2) Graphite column made by mixing materials: Graphite with a purity of 99.9% and the alloy powder obtained in step (1) are fully mixed according to the mass ratio of 1:1 and granulated with a granulator, and pressed into graphite column;

[0025] (3) Graphite column sintering: the graphite column obtained in step (2) was vacuum sintered at 400°C for 15 hours, and then reduced;

[0026] (4) Graphite column surface treatment: wrap the surface of the graphite column obtained in step (3) with 1mm thick pure iron as an oxygen r...

Embodiment 2

[0029] A method for preparing a surface-grooved diamond, comprising the following steps:

[0030] (1) Preparation of catalyst alloy powder: copper, manganese, chromium, niobium, and cobalt trace elements are added to the iron-based catalyst, and the catalyst alloy powder is composed of the following raw materials in mass percentage: 82.5% iron metal, 10% copper metal, and 2.5% manganese metal 1% of chromium metal, 1% of niobium, 3% of cobalt; then made into 250 mesh alloy powder;

[0031] (2) Graphite column made by mixing materials: Graphite with a purity of 99.9% and the alloy powder obtained in step (1) are fully mixed according to the mass ratio of 1:1 and granulated with a granulator, and pressed into graphite column;

[0032] (3) Graphite column sintering: the graphite column obtained in step (2) was vacuum sintered at 450°C for 12 hours, and then reduced;

[0033] (4) Graphite column surface treatment: wrap the surface of the graphite column obtained in step (3) with 1...

Embodiment 3

[0036] A method for preparing a surface-grooved diamond, comprising the following steps:

[0037] 1) Preparation of catalyst alloy powder: copper, manganese, chromium, niobium, and cobalt trace elements are added to the iron-based catalyst, and the catalyst alloy powder is composed of the following raw materials in mass percentage: iron 79%, copper 10%, manganese 3%, chromium 1.6% , niobium 1.6%, cobalt 4.8%; then made into 270 mesh alloy powder;

[0038] 2) Graphite column made by mixing materials: fully mix the graphite with a purity of 99.9% and the alloy powder obtained in step (1) according to the mass ratio of 1.2:1 and granulate it with a granulator, and press it into a graphite column;

[0039] 3) Graphite column sintering: the graphite column obtained in step (2) was vacuum sintered at 420°C for 17 hours, and then reduced;

[0040] 4) Graphite column surface treatment: wrap the surface of the graphite column obtained in step (3) with 1mm thick pure iron as an oxygen ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com