Municipal solid waste landfill waste leachate treatment device and method

A technology for landfill leachate and domestic waste, which is applied in the field of leachate treatment devices in domestic waste landfills. It can solve the problems of good effect, difficult treatment of high-salt concentrated liquid, and high cost of dosing chemicals.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0084] Leachate from a landfill (10 tons / day)

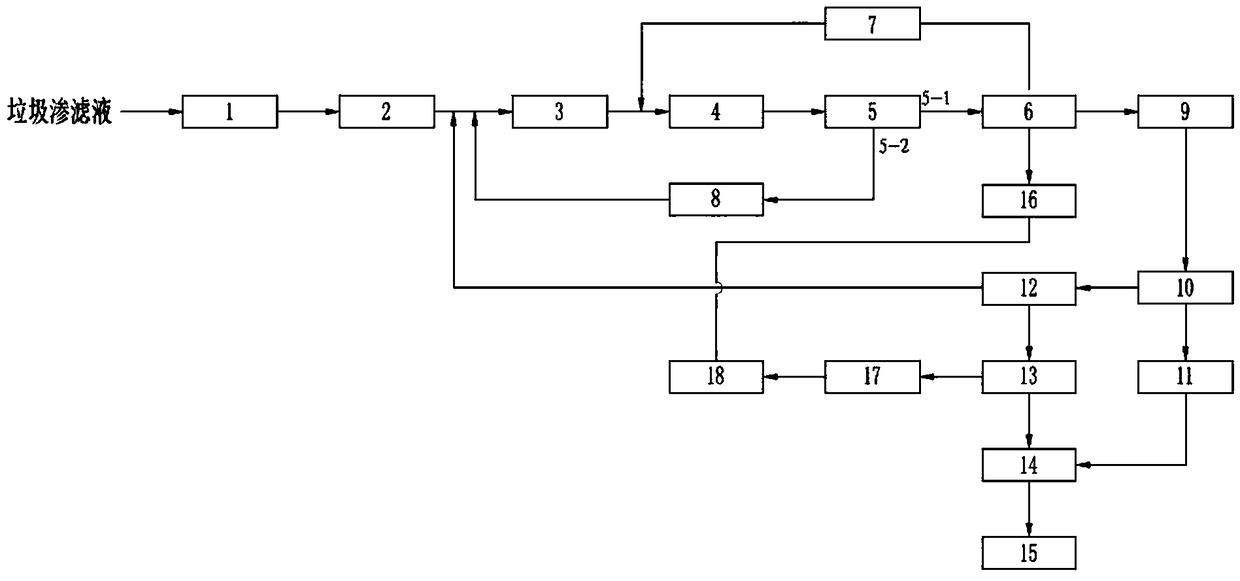

[0085] Processing devices such as figure 1 Shown:

[0086] Water intake: 10 tons / day;

[0087] The water quality of landfill leachate influent is shown in Table 1.

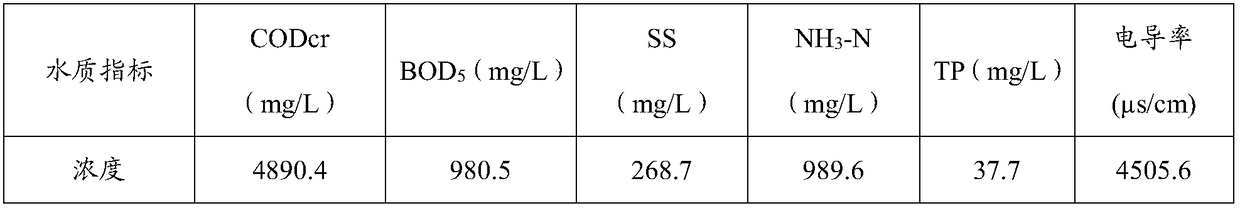

[0088] Table 1 Landfill leachate influent water quality

[0089]

[0090] The processing steps are as follows:

[0091] Garbage percolation passes through the grid / grid (1) to remove debris over 2mm and returns to the collection pool (2). After the above steps, the landfill leachate first enters the first-level anoxic pool (3), which is the same as the second-level The nitrifying liquid returned from the anoxic tank (5) is pre-denitrified by using the carbon source in the water (5-2), and then enters the aerobic tank (4) for further carbonization and nitrification, and then enters the secondary anoxic The pool (5) carries out endogenous denitrification, and the 200% mixed solution (R2) flows back to the primary anoxic pool (3) for pre-denitrification; the den...

Embodiment 2

[0116] Leachate from a landfill (10 tons / day)

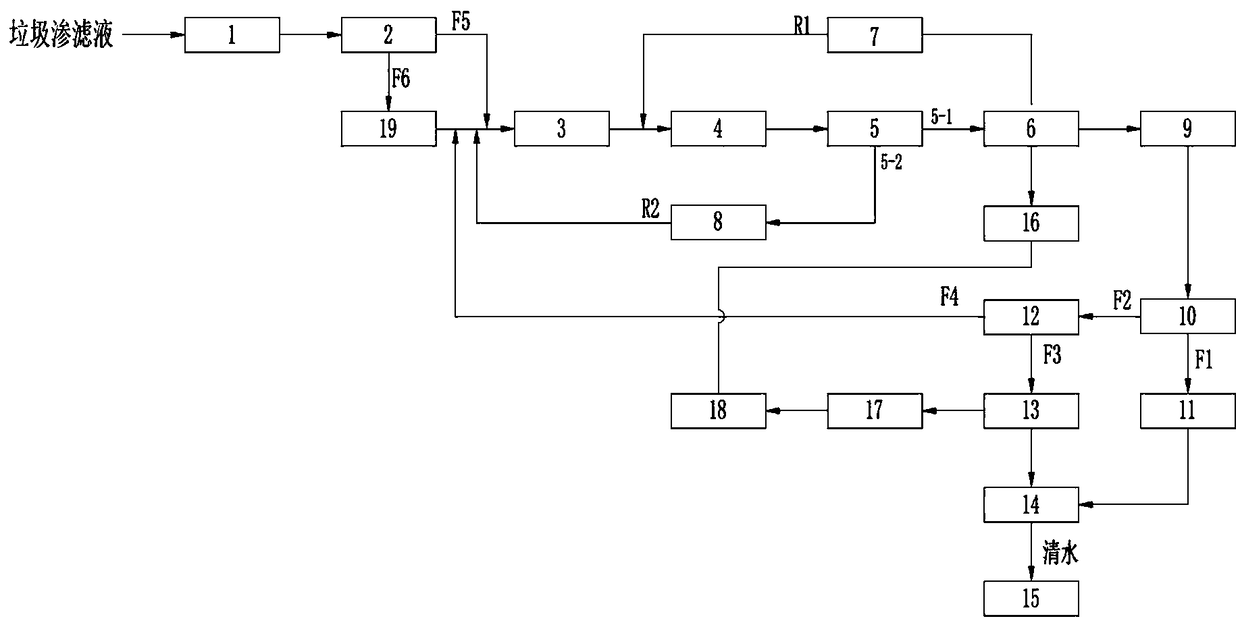

[0117] Processing devices such as figure 2 Shown:

[0118] Water intake: 10 tons / day;

[0119] The water quality of landfill leachate influent is shown in Table 3.

[0120] Table 3 Landfill leachate influent water quality

[0121]

[0122] The processing steps are as follows:

[0123] The landfill leachate passes through the grid / grid (1) to remove impurities larger than 2mm and then enters the collection tank (2), and most of the waste water (F6, 80%) undergoes anaerobic reaction in the anaerobic reaction tank (19) to remove large Part of the organic matter and a small part of waste water (F5, 20%) directly enter the primary anoxic pool (3), and the nitrifying liquid returned by the mixed liquid return pump (8) in the secondary anoxic pool (5) utilizes the carbon in the incoming water source for pre-denitrification, then enters the aerobic tank (4) for further carbonization and nitrification, then enters the secondary a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com