Method for non-pressure spark plasma sintering of ceramics

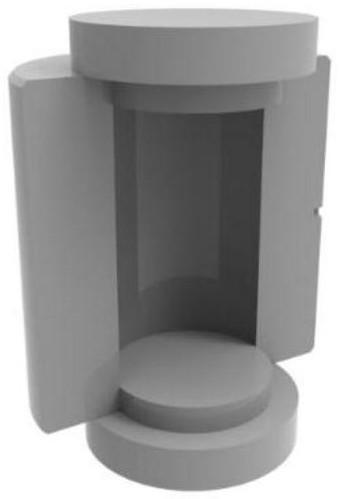

A technology of discharge plasma and sintered ceramics, which is applied in the field of preparation of inorganic non-metallic ceramics. It can solve the problems of single shape, axial/radial tissue composition and microstructure differences, etc., and achieve high density, uniform tissue composition, and improved tissue composition. and the effect of microstructural inhomogeneity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

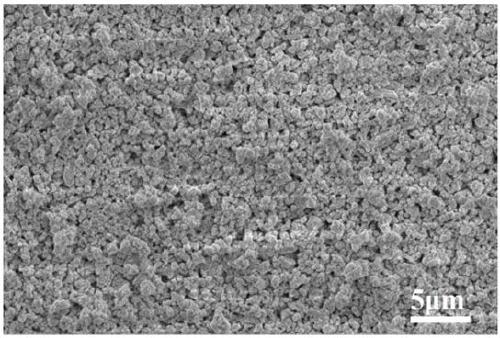

[0042] 45vol.% solid phase volume fraction, 1.2wt.% ammonium polyacrylate as dispersant, 5wt.% yttrium oxide and 2wt.% alumina as sintering aid, 5wt.% diacetate as curing agent for direct solidification injection molding ceramics The green body was sintered with pressureless discharge plasma at a heating rate of 100°C / min to 1700°C for 30 minutes to obtain silicon nitride ceramics.

[0043] Fully mix 93g of silicon nitride powder, 5g of yttrium oxide powder, 2g of alumina powder, 1.2g of ammonium polyacrylate and 35.95ml of deionized water, and ball mill for 120min at a ball milling speed of 300r / min to make it fully mixed evenly. 5:1, the grinding beads are made of silicon nitride ceramic balls to make a negatively charged ceramic slurry on the surface, then add 5g of diacetate, stir evenly, and place in a vacuum degasser for 15 minutes to remove the gas in the suspension , and then inject the ceramic slurry into a non-porous mold, and place it in a water bath at 70°C for 50 ...

Embodiment example 2

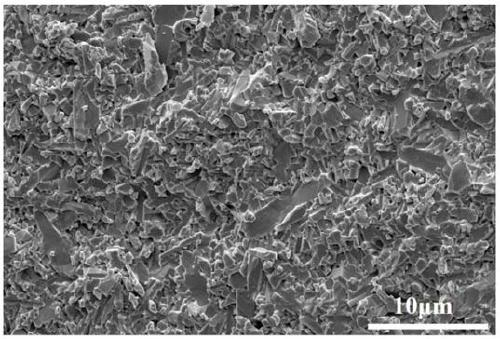

[0045] 65vol.% solid phase volume fraction, 0.1wt.% tetramethylammonium hydroxide as a dispersant, 2.0wt.% diacetate as a curing agent to directly solidify and inject molded ceramic green bodies at a heating rate of 300°C / min to Alumina ceramics were obtained by pressureless discharge plasma sintering at 1400°C for 5 minutes.

[0046] Fully mix 100g of alumina powder, 0.1g of tetramethylammonium hydroxide and 13.46ml of deionized water, and ball mill for 240min at a ball milling speed of 150r / min to fully mix them evenly. The ball-to-material ratio is 2:1. Zirconia ceramic balls, made of negatively charged ceramic slurry on the surface, then added 2g of diacetate, stirred evenly, placed in a vacuum degasser for 20min to remove the gas in the suspension, and then injected the ceramic slurry into the non-porous placed in the mold, and placed in a 60°C water bath for 120 minutes to solidify and form, and after the cured and formed ceramic wet blank was dried at 60°C for 48 hours,...

Embodiment example 3

[0048] 50vol.% solid phase volume fraction, 3.0wt.% ammonium citrate as a dispersant, 0.5wt.% agar powder as a curing agent, direct solidification and injection molding of ceramic green bodies, with a heating rate of 50°C / min to 1000°C without pressure Spark plasma sintering for 60min to obtain silicon dioxide ceramics.

[0049] Fully mix 100g of silica powder, 3.0g of ammonium citrate and 37.74ml of deionized water, and grind for 30 minutes at a ball milling speed of 450r / min to make them fully mixed. The ball-to-material ratio is 3:1, and the grinding beads are made of zirconia Ceramic balls, made of negatively charged ceramic slurry on the surface, then add 0.5g agar powder, stir evenly, place in a vacuum degasser for 30min to remove the gas in the suspension, and then inject the ceramic slurry into a non-porous mold , and put it in a water bath at 85°C for 10 minutes to solidify and form it, and dry the cured and formed ceramic wet blank at 70°C for 24 hours, and then plac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com