Heat-resistant low-smoke flame-retardant PVC cable

A low-smoke, flame-retardant, PVC resin technology, applied in the direction of insulating cables, cables, circuits, etc., can solve problems such as insufficient heat resistance, achieve reasonable proportioning, reduce manufacturing costs, and avoid thermal stress cracking problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

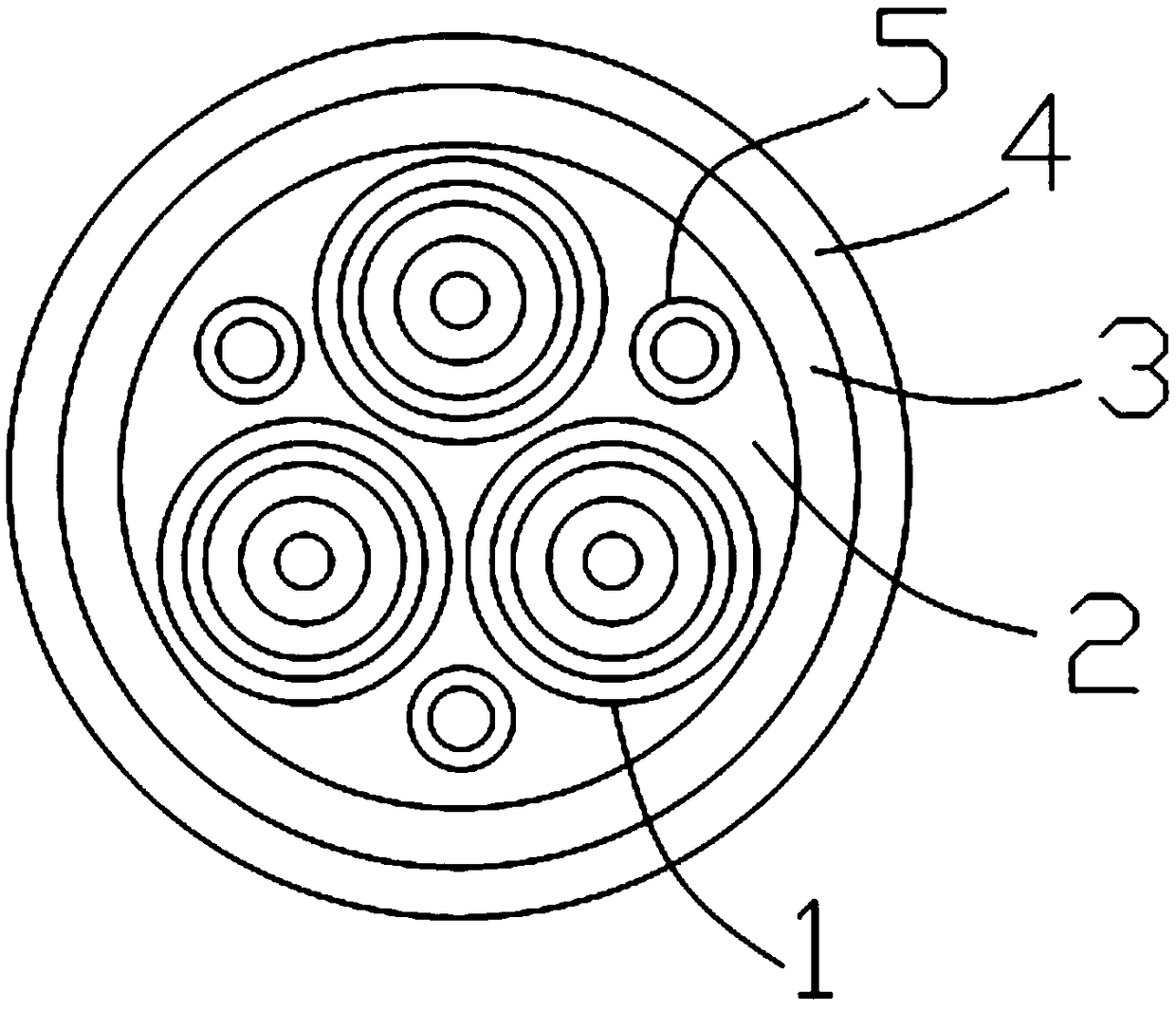

[0016] The heat-resistant, low-smoke, and flame-retardant PVC cable of this embodiment is composed of an aluminum alloy cable core 1, a filling layer 2, an ethylene-propylene rubber insulating layer 3, a heat-resistant and low-smoke-resistant PVC sheath 4, and a nickel cable core 5 Composition, the filling layer 2 is extruded with three aluminum alloy cable cores 1 and three nickel cable cores 5, the filling layer 2 is extruded and wrapped with a layer of ethylene-propylene rubber insulating layer 3, and the ethylene-propylene rubber insulating layer 3 is outside. A heat-resistant and low-smoke-resistance PVC jacket 4 is extruded; the raw materials of the heat-resistant and low-smoke-resistance PVC jacket 4 include the following components by weight:

[0017] 30 parts of PVC resin, 4 parts of styrene, 4 parts of 3-(2-furyl) acrylic acid, 4 parts of ethyl cinnamate, 5 parts of trioctyl trimellitate, 0.5 parts of epoxidized soybean oil, 1 part of calcium carbonate , 1 part of ca...

Embodiment 2

[0021] The heat-resistant, low-smoke, and flame-retardant PVC cable of this embodiment is composed of an aluminum alloy cable core 1, a filling layer 2, an ethylene-propylene rubber insulating layer 3, a heat-resistant and low-smoke-resistant PVC sheath 4, and a nickel cable core 5 Composition, the filling layer 2 is extruded with three aluminum alloy cable cores 1 and three nickel cable cores 5, the filling layer 2 is extruded and wrapped with a layer of ethylene-propylene rubber insulating layer 3, and the ethylene-propylene rubber insulating layer 3 is outside. A heat-resistant and low-smoke-resistance PVC jacket 4 is extruded; the raw materials of the heat-resistant and low-smoke-resistance PVC jacket 4 include the following components by weight:

[0022] 40 parts of PVC resin, 8 parts of styrene, 8 parts of 3-(2-furyl) acrylic acid, 8 parts of ethyl cinnamate, 10 parts of trioctyl trimellitate, 3 parts of epoxidized soybean oil, 4 parts of calcium carbonate , 4 parts of c...

Embodiment 3

[0026] The heat-resistant, low-smoke, and flame-retardant PVC cable of this embodiment is composed of an aluminum alloy cable core 1, a filling layer 2, an ethylene-propylene rubber insulating layer 3, a heat-resistant and low-smoke-resistant PVC sheath 4, and a nickel cable core 5 Composition, the filling layer 2 is extruded with three aluminum alloy cable cores 1 and three nickel cable cores 5, the filling layer 2 is extruded and wrapped with a layer of ethylene-propylene rubber insulating layer 3, and the ethylene-propylene rubber insulating layer 3 is outside. A heat-resistant and low-smoke-resistance PVC jacket 4 is extruded; the raw materials of the heat-resistant and low-smoke-resistance PVC jacket 4 include the following components by weight:

[0027] 30 parts of PVC resin, 8 parts of styrene, 4 parts of 3-(2-furyl) acrylic acid, 8 parts of ethyl cinnamate, 5 parts of trioctyl trimellitate, 3 parts of epoxidized soybean oil, 1 part of calcium carbonate , 4 parts of cal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com