A back-passivated crystalline silicon solar cell and a preparation method thereof

A solar cell and backside passivation technology, applied in the field of solar cells, can solve the problems of reducing minority carrier lifetime, increasing cell cracks and cracks, increasing recombination centers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

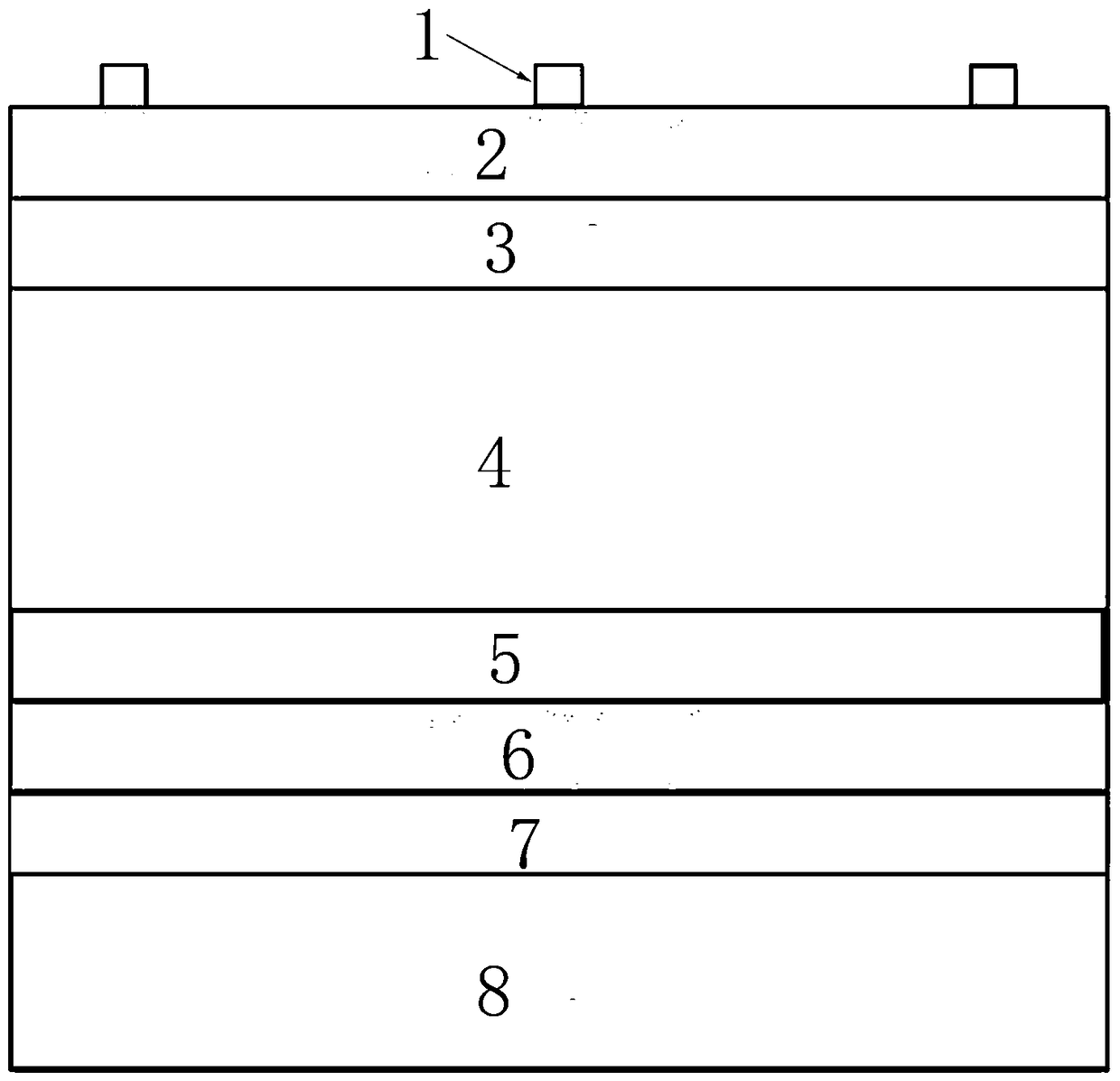

[0024] The crystalline silicon solar cell described in this embodiment uses molybdenum oxide as the p-type crystalline silicon passivation layer and the hole transport layer, and has the following structure: front Ag electrode 1, SiN x Layer (80nm) 2, n-c-Si layer 3, p-c-Si layer 4, SiO 2 Layer (1.2-1.5nm) 5, MoO 3 Layer (3nm) 6, Al layer (3nm) 7, back Ag electrode 8, wherein x=0.9-1.2, n-c-Si is phosphorus-doped n-type crystalline silicon.

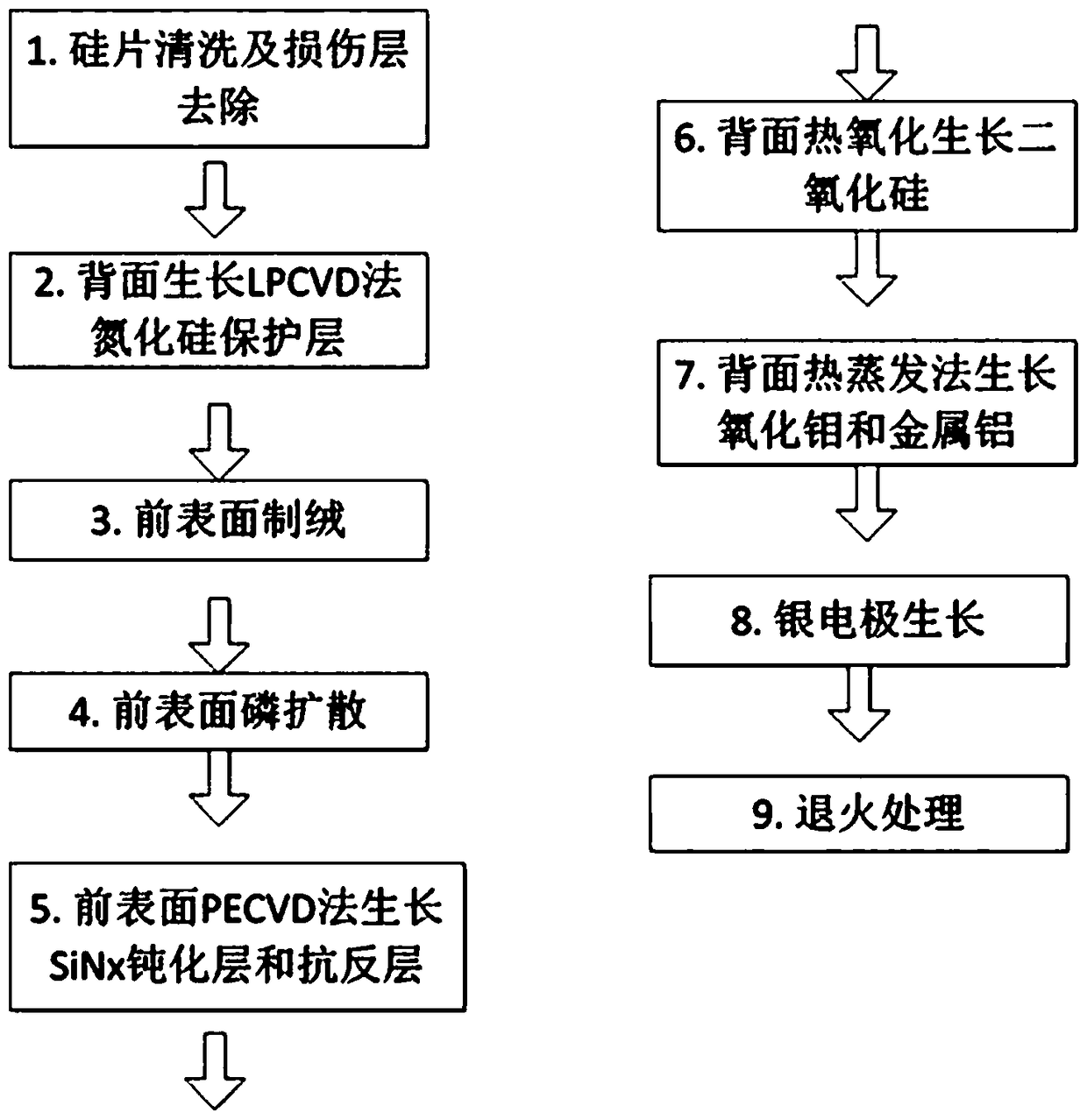

[0025] The preparation process of the battery is as follows:

[0026] 1) Cleaning and cashmere

[0027]The silicon wafer used in the experiment is a single crystal silicon wafer cut by diamond wire, with a resistivity of 0.5-1.5Ω.cm, a thickness of 180μm, and a size of 4×4cm. 2 . First, immerse the silicon wafer in acetone and absolute ethanol solution successively and use ultrasonic cleaning for 10 minutes to remove surface oil stains and dirt; secondly, treat the silicon wafer in a 30% sodium hydroxide solution at 80°C for 20 minute...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com